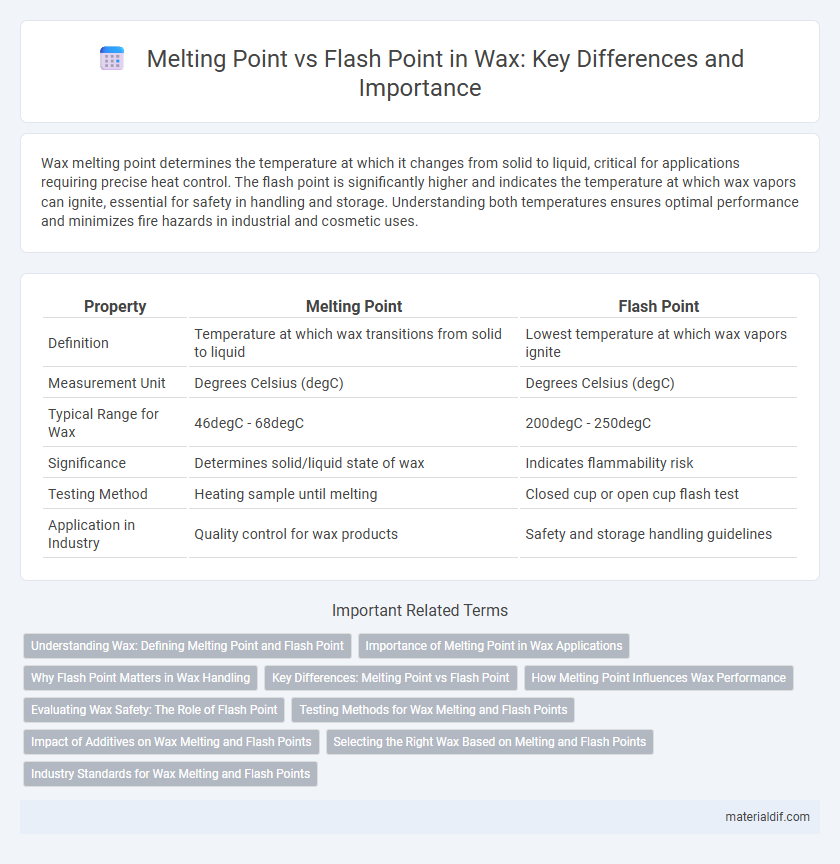

Wax melting point determines the temperature at which it changes from solid to liquid, critical for applications requiring precise heat control. The flash point is significantly higher and indicates the temperature at which wax vapors can ignite, essential for safety in handling and storage. Understanding both temperatures ensures optimal performance and minimizes fire hazards in industrial and cosmetic uses.

Table of Comparison

| Property | Melting Point | Flash Point |

|---|---|---|

| Definition | Temperature at which wax transitions from solid to liquid | Lowest temperature at which wax vapors ignite |

| Measurement Unit | Degrees Celsius (degC) | Degrees Celsius (degC) |

| Typical Range for Wax | 46degC - 68degC | 200degC - 250degC |

| Significance | Determines solid/liquid state of wax | Indicates flammability risk |

| Testing Method | Heating sample until melting | Closed cup or open cup flash test |

| Application in Industry | Quality control for wax products | Safety and storage handling guidelines |

Understanding Wax: Defining Melting Point and Flash Point

Melting point of wax is the specific temperature at which it transitions from solid to liquid, key for determining its usability in candles and cosmetics. Flash point, much higher than melting point, indicates the temperature where wax vapors ignite, crucial for safe handling and storage. Understanding both melting point and flash point ensures optimal wax performance and safety in various industrial applications.

Importance of Melting Point in Wax Applications

The melting point of wax is crucial in determining its suitability for various applications such as candle making, cosmetics, and pharmaceuticals, where precise temperature control ensures product stability and performance. Unlike the flash point, which indicates flammability risk, the melting point directly affects the texture, hardness, and melting behavior of wax, impacting processing and end-use quality. Accurate knowledge of the melting point allows manufacturers to select the right wax type for specific environmental conditions and functional requirements.

Why Flash Point Matters in Wax Handling

The flash point of wax is the temperature at which it can release enough vapor to ignite, making it a critical safety parameter in handling and storage. Unlike the melting point, which marks the transition from solid to liquid, the flash point directly indicates fire risk, essential for preventing accidents in industrial and candle-making processes. Strict monitoring of the flash point ensures proper ventilation and temperature control, minimizing the chance of ignition during heating or processing of wax.

Key Differences: Melting Point vs Flash Point

Melting point is the temperature at which wax transitions from a solid to a liquid, indicating its phase change threshold. Flash point refers to the lowest temperature at which wax vapors can ignite when exposed to an open flame, highlighting its flammability risk. These two properties serve distinct purposes: melting point measures physical state changes, while flash point assesses safety and combustion potential.

How Melting Point Influences Wax Performance

The melting point of wax critically determines its application and performance by indicating the temperature at which wax transitions from solid to liquid, affecting its stability and usability in various conditions. A wax with an appropriate melting point ensures optimal hardness, texture, and durability, enabling it to maintain shape and function in products such as candles, cosmetics, or coatings. The flash point, while important for safety, does not influence the physical properties or performance of wax like the melting point does.

Evaluating Wax Safety: The Role of Flash Point

The flash point of wax is a critical safety metric indicating the lowest temperature at which its vapors ignite, significantly impacting handling and storage precautions. While the melting point defines the temperature at which wax transitions from solid to liquid, it does not provide sufficient information about flammability risks. Evaluating wax safety requires prioritizing the flash point to prevent fire hazards during heating and application processes.

Testing Methods for Wax Melting and Flash Points

Wax melting point testing typically uses the ASTM D87 method, involving slow heating in a controlled environment to identify the temperature at which wax softens and loses its solid structure. Flash point testing follows ASTM D92, employing a Cleveland Open Cup tester to determine the lowest temperature at which wax vapors ignite when exposed to a flame. Accurate measurement of melting and flash points ensures wax quality, safety, and performance in industrial applications.

Impact of Additives on Wax Melting and Flash Points

Additives such as polymers, plasticizers, and fillers significantly influence the melting and flash points of wax, altering its thermal properties and combustion safety. Polymer additives typically raise the melting point by increasing molecular weight and structural rigidity, while plasticizers lower it by disrupting crystalline wax structures. Flash points can be elevated or reduced depending on the additive's volatility and chemical nature, impacting wax handling and application safety standards.

Selecting the Right Wax Based on Melting and Flash Points

Selecting the right wax requires understanding the melting point and flash point to ensure optimal performance and safety. Melting point determines the temperature at which wax transitions from solid to liquid, crucial for applications needing precise heat management, while the flash point indicates the temperature where wax vapors ignite, impacting fire risk and handling precautions. Choosing wax with a melting point matching the usage environment and a sufficiently high flash point ensures both functional effectiveness and safety compliance in products like candles, cosmetics, and industrial coatings.

Industry Standards for Wax Melting and Flash Points

Industry standards for wax melting and flash points ensure safety and quality in manufacturing and handling processes. The melting point defines the temperature at which wax transitions from solid to liquid, critical for product consistency, while the flash point indicates the lowest temperature at which wax vapors ignite, essential for fire hazard prevention. Regulatory agencies like ASTM International provide standardized testing methods and classification criteria to guide industrial practices and compliance.

Melting Point vs Flash Point Infographic

materialdif.com

materialdif.com