Melting point wax is designed to melt at a specific temperature, making it ideal for applications requiring precise thermal control, such as candle making or molding. Flexible point wax, on the other hand, remains pliable over a broader temperature range, providing durability and resistance to cracking in products like adhesives and coatings. Understanding the differences between melting point wax and flexible point wax helps in selecting the right type for specific industrial or crafting needs.

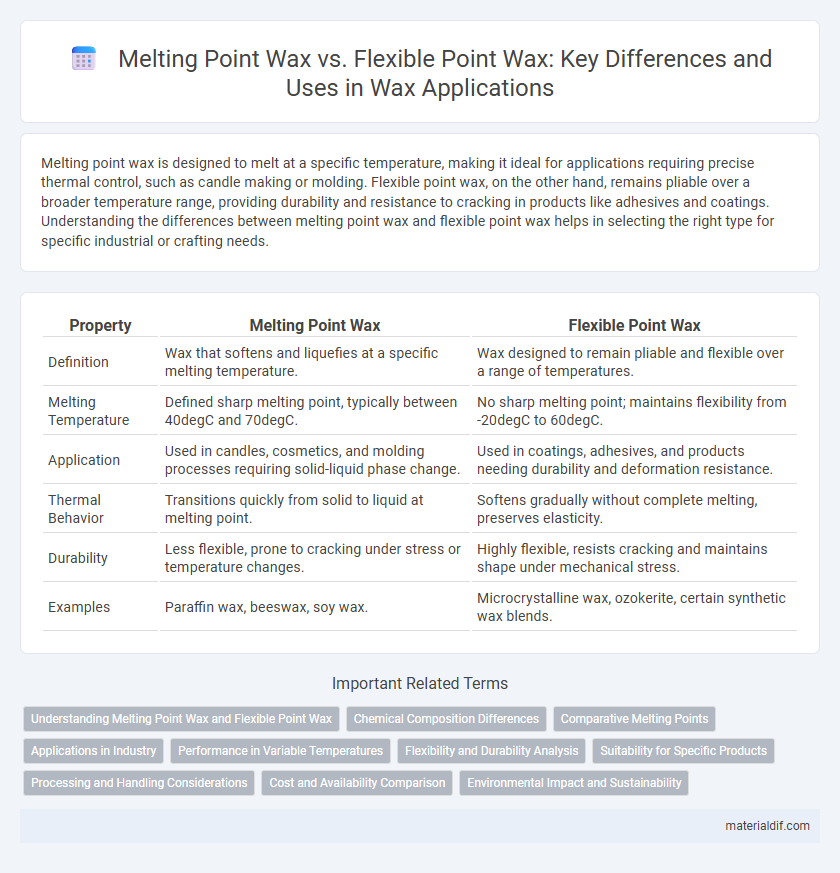

Table of Comparison

| Property | Melting Point Wax | Flexible Point Wax |

|---|---|---|

| Definition | Wax that softens and liquefies at a specific melting temperature. | Wax designed to remain pliable and flexible over a range of temperatures. |

| Melting Temperature | Defined sharp melting point, typically between 40degC and 70degC. | No sharp melting point; maintains flexibility from -20degC to 60degC. |

| Application | Used in candles, cosmetics, and molding processes requiring solid-liquid phase change. | Used in coatings, adhesives, and products needing durability and deformation resistance. |

| Thermal Behavior | Transitions quickly from solid to liquid at melting point. | Softens gradually without complete melting, preserves elasticity. |

| Durability | Less flexible, prone to cracking under stress or temperature changes. | Highly flexible, resists cracking and maintains shape under mechanical stress. |

| Examples | Paraffin wax, beeswax, soy wax. | Microcrystalline wax, ozokerite, certain synthetic wax blends. |

Understanding Melting Point Wax and Flexible Point Wax

Melting point wax is defined by the specific temperature at which it transitions from solid to liquid, crucial for applications requiring precise thermal control. Flexible point wax, in contrast, emphasizes the temperature at which wax maintains flexibility without cracking, essential for coatings and adhesives. Understanding these properties helps optimize wax selection for industrial processes involving temperature variations and mechanical stress.

Chemical Composition Differences

Melting point wax primarily consists of paraffin hydrocarbons with a high concentration of straight-chain alkanes, which provide a sharp phase transition at a specific temperature. Flexible point wax contains a higher proportion of branched-chain hydrocarbons and microcrystalline components that contribute to its pliability and gradual softening characteristic. The difference in chemical composition directly influences their thermal behavior, with melting point wax exhibiting a distinct melting threshold while flexible point wax maintains flexibility over a broader temperature range.

Comparative Melting Points

Melting point wax typically solidifies at higher temperatures, ranging between 58degC and 65degC, providing rigidity and structural stability suited for various applications. Flexible point wax, in contrast, melts at lower temperatures around 40degC to 50degC, maintaining pliability and flexibility even when exposed to mild heat. The comparative melting points highlight the distinction in their thermal behavior, with melting point wax favoring stiffness and flexible point wax enabling adaptability.

Applications in Industry

Melting point wax is commonly used in industries requiring precise temperature control, such as candle manufacturing, cosmetics, and pharmaceuticals, where it ensures consistent melting and solidification. Flexible point wax finds applications in packaging, coatings, and adhesives, offering durability and elasticity under varying stress conditions. Choosing between these wax types depends on the desired thermal behavior and mechanical flexibility in industrial processes.

Performance in Variable Temperatures

Melting point wax exhibits a sharp phase transition at a specific temperature, providing rigidity and structural integrity in stable thermal conditions. Flexible point wax offers a broader softening range, enhancing durability and pliability under fluctuating temperatures, preventing cracking and deformation. Performance in variable temperatures favors flexible point wax for applications requiring elasticity, while melting point wax suits environments demanding precise melting behavior.

Flexibility and Durability Analysis

Melting point wax typically solidifies at higher temperatures, offering rigidity but limited flexibility, making it ideal for structural applications. Flexible point wax remains pliable at varying temperatures, enhancing durability through resistance to cracking and deformation under stress. Evaluating both types highlights that flexible point wax provides superior adaptability and long-term resilience in dynamic environments.

Suitability for Specific Products

Melting point wax is ideal for products requiring rigidity and structural stability, such as candles and crayons, where maintaining shape under moderate heat is essential. Flexible point wax suits applications needing pliability and resistance to cracking, like coatings and adhesives, ensuring durability under stress and bending. Choosing the right wax type enhances product performance by aligning physical properties with specific functional requirements.

Processing and Handling Considerations

Melting point wax requires precise temperature control during processing to ensure it melts uniformly without degrading, which is critical for applications needing consistent solidification. Flexible point wax offers greater elasticity and can withstand bending or deformation without cracking, enhancing its handling in dynamic environments or flexible product formulations. Selecting the right wax involves balancing melting behavior and mechanical flexibility to optimize performance and manufacturability in specific industrial applications.

Cost and Availability Comparison

Melting point wax generally costs less than flexible point wax due to its simpler formulation and widespread availability in industrial markets. Flexible point wax, designed for applications requiring elasticity at various temperatures, tends to be more expensive as it incorporates specialized additives and is available in limited quantities. Both types of wax are accessible through major chemical suppliers, but melting point wax benefits from a broader distribution network, reducing overall procurement costs.

Environmental Impact and Sustainability

Melting point wax typically requires higher energy consumption for production and melting processes, leading to greater carbon emissions compared to flexible point wax, which melts at lower temperatures and reduces energy use. Flexible point wax often incorporates biodegradable and renewable materials, enhancing its sustainability profile over traditional melting point waxes derived from petroleum-based sources. Selecting flexible point wax can significantly decrease environmental impact by minimizing fossil fuel dependency and improving the wax's end-of-life biodegradability.

Melting Point Wax vs Flexible Point Wax Infographic

materialdif.com

materialdif.com