Blending waxes combine multiple types of wax to enhance flexibility, adhesion, and durability, making them ideal for complex applications requiring varied performance characteristics. Pure wax application offers a consistent, uniform texture and melting point, which is preferred for precise, specialized uses where product purity and stability are critical. Selecting between blended or pure wax depends on the desired balance between performance needs and formulation consistency in cosmetic, industrial, or art-related products.

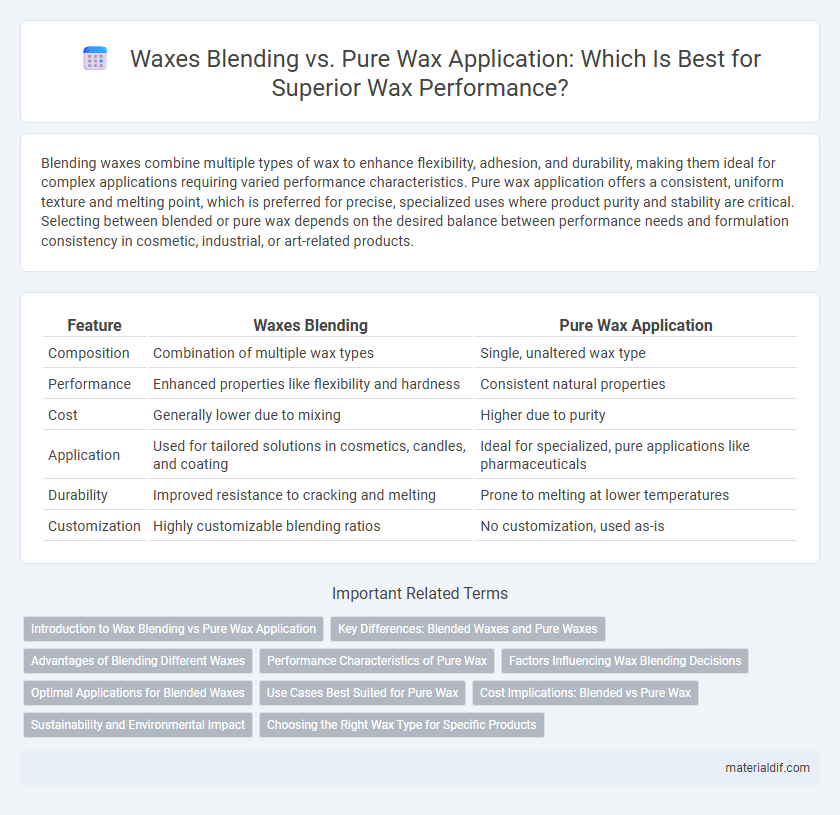

Table of Comparison

| Feature | Waxes Blending | Pure Wax Application |

|---|---|---|

| Composition | Combination of multiple wax types | Single, unaltered wax type |

| Performance | Enhanced properties like flexibility and hardness | Consistent natural properties |

| Cost | Generally lower due to mixing | Higher due to purity |

| Application | Used for tailored solutions in cosmetics, candles, and coating | Ideal for specialized, pure applications like pharmaceuticals |

| Durability | Improved resistance to cracking and melting | Prone to melting at lower temperatures |

| Customization | Highly customizable blending ratios | No customization, used as-is |

Introduction to Wax Blending vs Pure Wax Application

Wax blending combines multiple wax types to enhance performance characteristics such as melting point, hardness, and scent retention, offering greater versatility than pure wax application. Pure wax application uses a single type of wax, ensuring consistency and purity, often preferred for natural or specialty products. Understanding the differences helps in selecting the optimal wax formula for specific candle-making or industrial needs.

Key Differences: Blended Waxes and Pure Waxes

Blended waxes combine natural and synthetic components to optimize properties like melting point, hardness, and flexibility, offering enhanced performance and adaptability for various applications. Pure waxes, derived from a single source such as beeswax or carnauba, provide consistent natural properties and purity but may lack the tailored characteristics found in blends. The choice between blended and pure waxes depends on factors like desired durability, texture, application method, and cost-efficiency in industries ranging from cosmetics to industrial coatings.

Advantages of Blending Different Waxes

Blending different waxes creates formulations with enhanced thermal stability, improved texture, and optimized melting points, offering superior performance compared to pure wax applications. This method allows customization of hardness, flexibility, and gloss levels to meet specific industrial or cosmetic requirements. Combining waxes also improves adhesive properties and durability, making blended waxes more versatile and effective in various uses like candle making, cosmetics, and coatings.

Performance Characteristics of Pure Wax

Pure wax offers superior performance characteristics such as enhanced durability, consistent melting points, and greater thermal stability compared to wax blends. Its uniform molecular structure ensures predictable behavior in applications requiring precise temperature control and extended wear resistance. Pure wax is preferred in high-quality candle making and specialty coatings where purity directly impacts opacity, scent retention, and burn time.

Factors Influencing Wax Blending Decisions

Factors influencing wax blending decisions include desired melting point, hardness, and flexibility tailored for specific applications such as cosmetics, candles, or industrial uses. Blending allows customization by combining properties of different waxes, optimizing performance like burn time, scent retention, and texture. Cost-effectiveness and availability of raw materials also play crucial roles when choosing between pure wax application and blends.

Optimal Applications for Blended Waxes

Blended waxes combine natural and synthetic components to optimize melting points and improve durability, making them ideal for applications requiring precise performance characteristics. These blends offer enhanced flexibility and adhesion compared to pure waxes, resulting in better wear resistance and smoother finishes in cosmetics, candles, and industrial coatings. Utilizing blended waxes ensures consistent quality and user experience across a range of temperatures and environments, maximizing application efficiency.

Use Cases Best Suited for Pure Wax

Pure wax applications excel in scenarios requiring superior barrier protection, such as in cosmetics and food packaging, due to their unmatched purity and consistency. They are ideal for sensitive formulations where additives in blended waxes may cause adverse reactions or alter product performance. Medical dressings, specialty candles, and luxury skincare products benefit from pure wax's natural properties and predictable behavior.

Cost Implications: Blended vs Pure Wax

Blended waxes typically offer cost advantages over pure wax due to the use of additives and fillers that reduce material expenses without significantly compromising performance. Pure wax applications, while often delivering superior quality and consistency, involve higher raw material costs that increase overall production expenses. Manufacturers must balance these cost implications with performance requirements when selecting between blended and pure wax formulations.

Sustainability and Environmental Impact

Blending waxes with sustainable bio-based ingredients reduces reliance on petroleum-derived paraffin, lowering carbon footprints and enhancing biodegradability. Pure wax applications, typically using beeswax or soy wax, offer naturally renewable sourcing but may lack the performance versatility and cost-effectiveness of blended formulations. Selecting eco-friendly blends optimized for minimal environmental impact supports sustainable production while meeting diverse consumer needs.

Choosing the Right Wax Type for Specific Products

Blends of waxes offer tailored properties like enhanced flexibility, melting point, and texture, making them ideal for products such as candles, cosmetics, and polishes requiring specific performance characteristics. Pure waxes, like beeswax or paraffin, provide consistent purity and natural qualities preferred in applications demanding minimal additives or allergen-free ingredients. Selecting the right wax type depends on the desired hardness, melting range, and compatibility with other ingredients to optimize product functionality and consumer appeal.

Waxes Blending vs Pure Wax Application Infographic

materialdif.com

materialdif.com