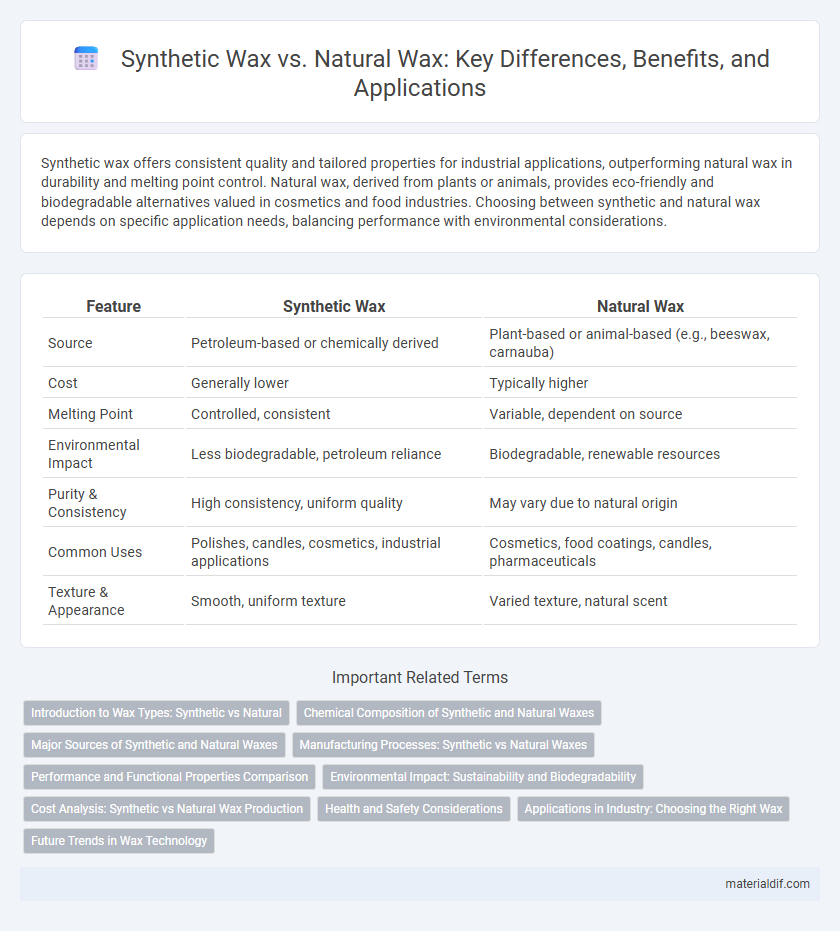

Synthetic wax offers consistent quality and tailored properties for industrial applications, outperforming natural wax in durability and melting point control. Natural wax, derived from plants or animals, provides eco-friendly and biodegradable alternatives valued in cosmetics and food industries. Choosing between synthetic and natural wax depends on specific application needs, balancing performance with environmental considerations.

Table of Comparison

| Feature | Synthetic Wax | Natural Wax |

|---|---|---|

| Source | Petroleum-based or chemically derived | Plant-based or animal-based (e.g., beeswax, carnauba) |

| Cost | Generally lower | Typically higher |

| Melting Point | Controlled, consistent | Variable, dependent on source |

| Environmental Impact | Less biodegradable, petroleum reliance | Biodegradable, renewable resources |

| Purity & Consistency | High consistency, uniform quality | May vary due to natural origin |

| Common Uses | Polishes, candles, cosmetics, industrial applications | Cosmetics, food coatings, candles, pharmaceuticals |

| Texture & Appearance | Smooth, uniform texture | Varied texture, natural scent |

Introduction to Wax Types: Synthetic vs Natural

Synthetic waxes are chemically engineered substances designed to replicate the properties of natural waxes while offering enhanced consistency and durability for industrial applications. Natural waxes, derived from plant, animal, or mineral sources, provide ecological benefits and unique chemical compositions that vary based on their origin, such as beeswax, carnauba, or paraffin. Understanding the differences in melting points, texture, and biodegradability between synthetic and natural waxes is essential for selecting the appropriate wax type in manufacturing, cosmetics, and food industries.

Chemical Composition of Synthetic and Natural Waxes

Synthetic waxes are primarily composed of long-chain hydrocarbons derived from petroleum, including polyethylene, Fischer-Tropsch waxes, and other synthetic polymers featuring uniform molecular structures. Natural waxes, such as beeswax, carnauba, and paraffin, contain complex mixtures of esters, fatty acids, alcohols, and hydrocarbons with diverse molecular weights and structures. The chemical composition of synthetic waxes allows for greater consistency and tailored properties, while natural waxes exhibit variability due to their botanical or animal origins.

Major Sources of Synthetic and Natural Waxes

Synthetic waxes primarily derive from petroleum-based hydrocarbons, including paraffin wax, microcrystalline wax, and polyethylene wax, produced through refining crude oil. Natural waxes originate from plant and animal sources, such as carnauba wax from Brazilian palm leaves, beeswax from honeybee hives, and montan wax extracted from lignite. Industrial uses often dictate the choice between synthetic and natural waxes based on their source properties, like melting point and hardness.

Manufacturing Processes: Synthetic vs Natural Waxes

Synthetic waxes are typically produced through chemical synthesis involving polymers or petroleum derivatives, allowing precise control over melting points and molecular structures. Natural waxes are extracted from biological sources such as plants, animals, and minerals using mechanical or solvent-based methods, resulting in complex mixtures of esters, fatty acids, and hydrocarbons. Manufacturing synthetic waxes offers consistency and customization advantages, while natural waxes provide biodegradability and inherent organic properties.

Performance and Functional Properties Comparison

Synthetic wax offers superior consistency and higher melting points compared to natural wax, enhancing durability and thermal stability in diverse applications. Natural waxes provide better biodegradability and inherent lubricity, making them ideal for eco-friendly and skin-sensitive products. Performance optimization depends on balancing synthetic wax's chemical uniformity with the renewable characteristics and bio-based benefits of natural waxes.

Environmental Impact: Sustainability and Biodegradability

Synthetic waxes, derived from petrochemicals, pose environmental challenges due to their non-renewable origins and slow biodegradability, leading to longer-lasting ecological footprints. Natural waxes, such as beeswax and carnauba wax, offer greater sustainability and faster biodegradability because they are sourced from renewable plants or animals and break down more readily in ecosystems. Choosing natural waxes reduces reliance on fossil fuels and minimizes long-term environmental pollution.

Cost Analysis: Synthetic vs Natural Wax Production

Synthetic wax production generally incurs lower costs due to the use of readily available petroleum-based raw materials and efficient industrial processes, resulting in higher scalability and consistency. Natural wax, derived from sources such as beeswax or plant-based materials, involves higher extraction and purification expenses, contributing to its premium pricing and limited supply. Market demand trends and environmental regulations further impact cost dynamics, often making synthetic wax a more economical choice for large-scale applications.

Health and Safety Considerations

Synthetic wax, often derived from petrochemicals, may release potentially harmful volatile organic compounds (VOCs) when heated, posing respiratory risks and skin irritation concerns. Natural waxes, such as beeswax or soy wax, are typically biodegradable and emit fewer toxins, making them safer for indoor air quality and human health. Evaluating the source and chemical composition of waxes is crucial for minimizing health hazards in candle making and cosmetic applications.

Applications in Industry: Choosing the Right Wax

Synthetic wax offers superior consistency and tailored properties ideal for industrial applications like coatings, adhesives, and plastics, ensuring enhanced performance and durability. Natural wax, derived from plants or animals, is favored in cosmetics, pharmaceuticals, and food processing for its biodegradability and skin-friendly characteristics. Selecting the appropriate wax depends on factors such as thermal stability, environmental impact, and end-use requirements in the manufacturing process.

Future Trends in Wax Technology

Synthetic waxes, engineered from petrochemical or polymer sources, offer enhanced consistency, melting points, and durability compared to natural waxes like beeswax or carnauba. Future trends emphasize bio-based synthetic waxes combining sustainability with tailored performance in cosmetics, packaging, and coatings industries. Advances in nanotechnology and green chemistry are driving the development of hybrid wax formulations that optimize biodegradability while maintaining superior functional properties.

Synthetic wax vs Natural wax Infographic

materialdif.com

materialdif.com