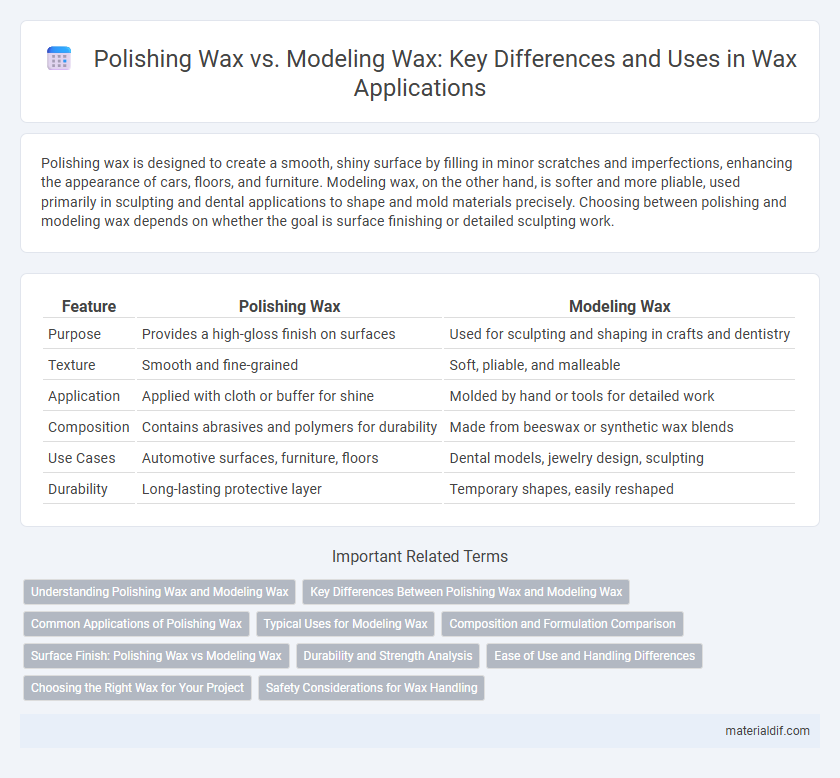

Polishing wax is designed to create a smooth, shiny surface by filling in minor scratches and imperfections, enhancing the appearance of cars, floors, and furniture. Modeling wax, on the other hand, is softer and more pliable, used primarily in sculpting and dental applications to shape and mold materials precisely. Choosing between polishing and modeling wax depends on whether the goal is surface finishing or detailed sculpting work.

Table of Comparison

| Feature | Polishing Wax | Modeling Wax |

|---|---|---|

| Purpose | Provides a high-gloss finish on surfaces | Used for sculpting and shaping in crafts and dentistry |

| Texture | Smooth and fine-grained | Soft, pliable, and malleable |

| Application | Applied with cloth or buffer for shine | Molded by hand or tools for detailed work |

| Composition | Contains abrasives and polymers for durability | Made from beeswax or synthetic wax blends |

| Use Cases | Automotive surfaces, furniture, floors | Dental models, jewelry design, sculpting |

| Durability | Long-lasting protective layer | Temporary shapes, easily reshaped |

Understanding Polishing Wax and Modeling Wax

Polishing wax is designed to create a high-gloss, protective finish on surfaces such as wood, metal, and automotive paint, enhancing appearance while sealing against moisture and contaminants. Modeling wax, often used in sculpting and dental applications, is pliable and easy to shape, allowing precise detail work and adjustments before hardening. Understanding the distinct purposes and formulations of these waxes ensures optimal results in finishing or modeling projects.

Key Differences Between Polishing Wax and Modeling Wax

Polishing wax is designed primarily for creating a smooth, shiny surface on finished metal or wood, offering protection and enhancing appearance with fine abrasives and buffs, whereas modeling wax is a softer, malleable material used in sculpting and dental applications to shape and refine details before final casting. Polishing wax contains abrasive particles that facilitate surface refinement, while modeling wax emphasizes workability and ease of carving without abrasive components. The key differences lie in composition, application purpose, and end results: polishing wax enhances surface finish and durability, whereas modeling wax supports detailed shaping and prototyping.

Common Applications of Polishing Wax

Polishing wax is commonly used for enhancing the surface finish of metals, wood, and automotive paint, providing a smooth, glossy shine while protecting against oxidation and corrosion. It is ideal for restoring luster on furniture, musical instruments, and vehicle exteriors, ensuring durability and aesthetic appeal. Unlike modeling wax, polishing wax is designed primarily for surface treatment rather than sculpting or shaping.

Typical Uses for Modeling Wax

Modeling wax is primarily used in dental and jewelry applications for creating detailed prototypes and intricate designs due to its pliable and easily sculpted nature. Unlike polishing wax, which enhances surface shine and protects finishes, modeling wax serves as a medium for shaping, fitting, and testing before final production. Its typical uses include fabricating dental crowns, bridges, and patterns for casting metal components with high precision.

Composition and Formulation Comparison

Polishing wax primarily consists of fine abrasives and oils designed to create a smooth, glossy finish on surfaces by gently removing micro-scratches. Modeling wax, formulated with higher concentrations of beeswax or synthetic waxes and softer resins, offers malleability and sculpting capabilities ideal for shaping and detailing. The key compositional difference lies in abrasives and fluidity agents in polishing wax versus pliable wax blends in modeling wax, tailoring each for their respective applications.

Surface Finish: Polishing Wax vs Modeling Wax

Polishing wax delivers a high-gloss, smooth surface finish by filling in micro-scratches and enhancing the sheen of materials like wood, metal, or stone. Modeling wax, designed for sculpting and shaping, typically leaves a matte or textured surface due to its thicker consistency and pliability. Choosing polishing wax over modeling wax is essential when the goal is to achieve a pristine, reflective finish rather than a sculpted form.

Durability and Strength Analysis

Polishing wax offers superior durability due to its hardening agents that create a resilient, protective layer on surfaces, making it ideal for long-lasting gloss and scratch resistance. Modeling wax, in contrast, prioritizes malleability and strength for sculpting and shaping purposes, resulting in firmness that withstands deformation but less surface hardness. The strength of polishing wax lies in its resistance to wear, while modeling wax excels in structural integrity and flexibility during detailed manipulation.

Ease of Use and Handling Differences

Polishing wax is designed for smooth application and quick buffing, making it user-friendly for achieving high-gloss finishes with minimal effort. Modeling wax, in contrast, offers greater pliability and sculpting control, requiring more skill to shape detailed forms but providing enhanced precision in artistic or dental applications. Ease of use thus depends on the task, with polishing wax favored for surface refinement and modeling wax preferred for intricate handling and customization.

Choosing the Right Wax for Your Project

Polishing wax creates a smooth, glossy finish ideal for enhancing surfaces like wood, metal, and automotive paint, providing protection from moisture and scratches. Modeling wax, typically softer and malleable, is better suited for sculpting, dental applications, and prototyping due to its flexibility and ability to hold detailed shapes. Selecting the right wax depends on whether your project requires a durable, polished surface or a workable, shapeable material.

Safety Considerations for Wax Handling

Polishing wax and modeling wax differ significantly in their chemical compositions, affecting their safety profiles during handling. Polishing wax often contains abrasives and solvents that require adequate ventilation and protective gloves to prevent skin irritation and respiratory issues. Modeling wax, typically made from natural or synthetic waxes with fewer additives, poses lower toxicity risks but still demands caution to avoid ingestion or prolonged skin contact.

Polishing Wax vs Modeling Wax Infographic

materialdif.com

materialdif.com