Fischer-Tropsch wax, derived from synthetic hydrocarbons produced through gas-to-liquid processes, offers superior purity and uniform molecular structure compared to petroleum wax, which is a byproduct of crude oil refining. This difference results in Fischer-Tropsch wax having higher melting points, better chemical stability, and enhanced hardness, making it ideal for specialized industrial applications such as cosmetics, pharmaceuticals, and high-performance coatings. Petroleum wax remains more cost-effective and widely used in packaging, candle making, and rubber industries due to its availability and established supply chain.

Table of Comparison

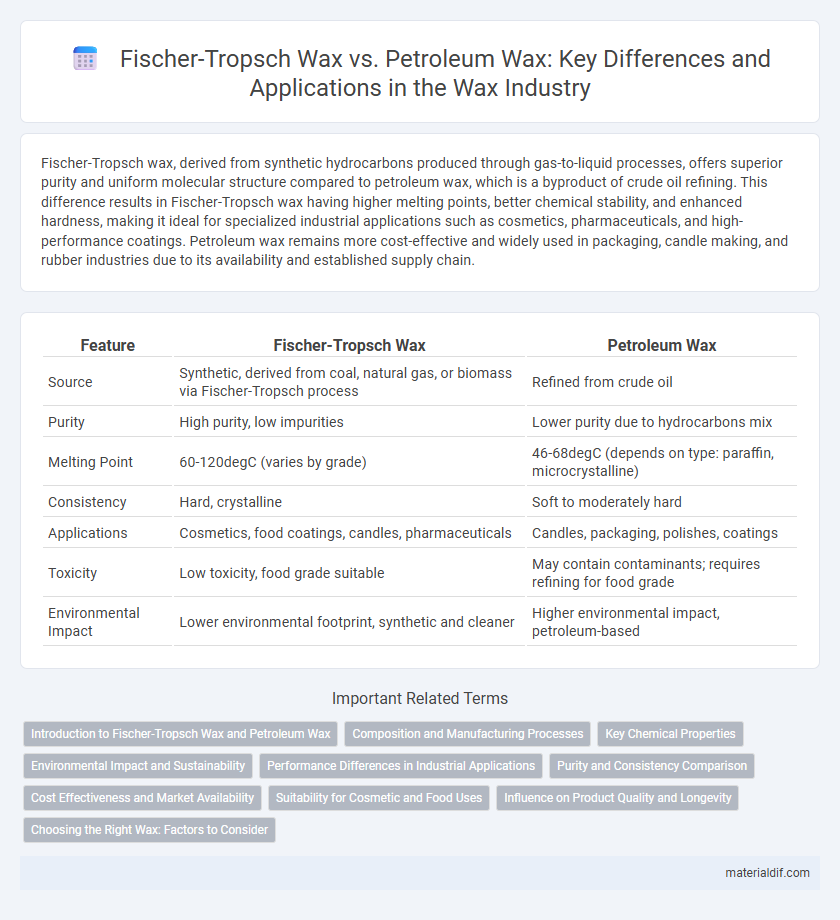

| Feature | Fischer-Tropsch Wax | Petroleum Wax |

|---|---|---|

| Source | Synthetic, derived from coal, natural gas, or biomass via Fischer-Tropsch process | Refined from crude oil |

| Purity | High purity, low impurities | Lower purity due to hydrocarbons mix |

| Melting Point | 60-120degC (varies by grade) | 46-68degC (depends on type: paraffin, microcrystalline) |

| Consistency | Hard, crystalline | Soft to moderately hard |

| Applications | Cosmetics, food coatings, candles, pharmaceuticals | Candles, packaging, polishes, coatings |

| Toxicity | Low toxicity, food grade suitable | May contain contaminants; requires refining for food grade |

| Environmental Impact | Lower environmental footprint, synthetic and cleaner | Higher environmental impact, petroleum-based |

Introduction to Fischer-Tropsch Wax and Petroleum Wax

Fischer-Tropsch wax is a synthetic wax produced through the Fischer-Tropsch process, which converts carbon monoxide and hydrogen into hydrocarbons, yielding a high-purity, uniform product with excellent thermal stability and low impurities. Petroleum wax, derived from crude oil refining, contains microcrystalline and paraffin waxes with variable melting points and impurities affecting consistency and performance. Fischer-Tropsch waxes are favored in applications requiring precise physical properties, such as cosmetics and specialty coatings, while petroleum waxes remain widely used in candles, packaging, and industrial lubricants.

Composition and Manufacturing Processes

Fischer-Tropsch wax, produced through the Fischer-Tropsch synthesis process, is primarily composed of long-chain linear hydrocarbons with high purity and uniform molecular structure, resulting from catalytic conversion of synthesis gas. Petroleum wax is derived from refining crude oil and consists of a mixture of saturated hydrocarbons with varying molecular weights, including paraffin, microcrystalline, and slack waxes. The manufacturing process of Fischer-Tropsch wax involves gas-to-liquid technology with controlled catalytic reactions, whereas petroleum wax is obtained through solvent dewaxing and refining of petroleum fractions.

Key Chemical Properties

Fischer-Tropsch wax is characterized by a high melting point, excellent chemical purity, and a straight-chain hydrocarbon structure, making it highly crystalline and uniform. Petroleum wax, derived from crude oil refining, contains branched hydrocarbons and varying impurities, resulting in lower melting points and less consistency. The key chemical difference impacts their applications, with Fischer-Tropsch wax offering superior thermal stability and odorless properties compared to petroleum wax.

Environmental Impact and Sustainability

Fischer-Tropsch wax, derived from synthetic hydrocarbons through gas-to-liquid technology, offers superior environmental benefits compared to petroleum wax, which is extracted from crude oil refining byproducts. The production of Fischer-Tropsch wax results in lower greenhouse gas emissions and reduced sulfur content, enhancing sustainability and reducing environmental pollution. In contrast, petroleum wax relies on fossil fuel extraction processes that contribute significantly to carbon emissions, making Fischer-Tropsch wax a more eco-friendly and sustainable alternative in industrial applications.

Performance Differences in Industrial Applications

Fischer-Tropsch wax offers superior purity and consistent molecular structure compared to petroleum wax, resulting in enhanced thermal stability and lower odor in industrial applications. Its high melting point and excellent compatibility improve performance in coatings, cosmetics, and adhesives, whereas petroleum wax may exhibit variability in hardness and melting behavior. Consequently, Fischer-Tropsch wax ensures better processing efficiency and product quality in high-demand industrial uses.

Purity and Consistency Comparison

Fischer-Tropsch wax offers superior purity compared to petroleum wax due to its synthetic origin, resulting in fewer impurities and a more uniform molecular structure. The consistency of Fischer-Tropsch wax remains stable across batches, ensuring predictable performance in applications such as cosmetics and coatings. Petroleum wax often contains variable hydrocarbon chains and contaminants, leading to fluctuating consistency and lower overall purity.

Cost Effectiveness and Market Availability

Fischer-Tropsch wax offers higher purity and uniform molecular structure, making it ideal for specialized industrial applications, though it often comes at a higher cost compared to petroleum wax. Petroleum wax remains more cost-effective and widely available due to its large-scale refining process and established supply chains. Market availability favors petroleum wax because of consistent global production and lower price points, while Fischer-Tropsch wax occupies niche markets requiring premium performance.

Suitability for Cosmetic and Food Uses

Fischer-Tropsch wax, derived from the catalytic conversion of carbon monoxide and hydrogen, exhibits high purity, consistent melting points, and low aromatic content, making it highly suitable for cosmetic and food applications requiring safety and hypoallergenic properties. Petroleum wax, sourced from refining crude oil, contains variable amounts of aromatic hydrocarbons and impurities, which may limit its use in sensitive formulations such as lip balms, creams, and food-grade coatings. The superior chemical stability and lack of contaminants in Fischer-Tropsch wax enhance product performance and compliance with stringent regulatory standards in cosmetics and food industries.

Influence on Product Quality and Longevity

Fischer-Tropsch wax, derived from gas-to-liquid processes, exhibits superior purity and uniform molecular structure compared to petroleum wax, which contains a wider range of hydrocarbons and impurities. This higher purity enhances product quality by providing better clarity, odorlessness, and consistent melting points, significantly extending the longevity of coatings, candles, and cosmetics. Petroleum waxes, though economical, may degrade faster due to the presence of aromatic compounds and varying chain lengths, potentially reducing overall product stability and shelf life.

Choosing the Right Wax: Factors to Consider

Fischer-Tropsch wax, derived from synthetic hydrocarbons via gas-to-liquid technology, offers superior purity and consistency compared to petroleum wax, which is sourced from crude oil refining. Factors to consider when choosing between these waxes include application requirements such as melting point, hardness, odor, and chemical stability, alongside environmental impact and production sustainability. Evaluating these properties ensures selection of the optimal wax for industries ranging from cosmetics to packaging and pharmaceuticals.

Fischer-Tropsch Wax vs Petroleum Wax Infographic

materialdif.com

materialdif.com