Refined wax offers a higher purity level than crude wax, resulting in a smoother texture and more consistent melting point ideal for pet care applications. Crude wax contains natural impurities that can affect the quality and safety of products used in pet grooming or veterinary treatments. Selecting refined wax ensures better performance and reduced risk of skin irritation for pets.

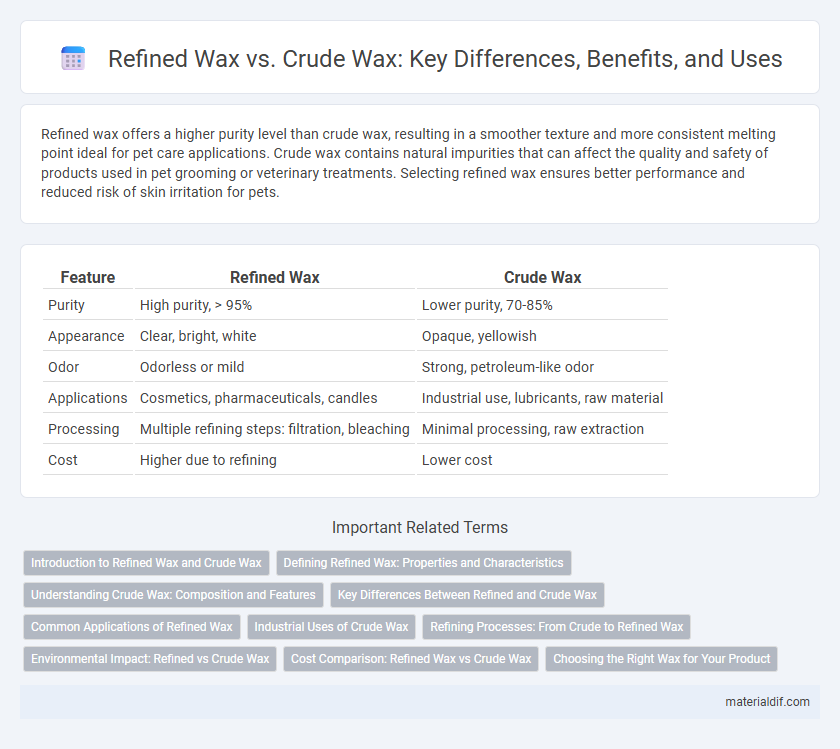

Table of Comparison

| Feature | Refined Wax | Crude Wax |

|---|---|---|

| Purity | High purity, > 95% | Lower purity, 70-85% |

| Appearance | Clear, bright, white | Opaque, yellowish |

| Odor | Odorless or mild | Strong, petroleum-like odor |

| Applications | Cosmetics, pharmaceuticals, candles | Industrial use, lubricants, raw material |

| Processing | Multiple refining steps: filtration, bleaching | Minimal processing, raw extraction |

| Cost | Higher due to refining | Lower cost |

Introduction to Refined Wax and Crude Wax

Refined wax undergoes extensive purification processes to remove impurities, resulting in a cleaner, high-quality product with consistent melting points and enhanced odorless or mild fragrance properties ideal for candle making and cosmetics. Crude wax is the unprocessed or minimally processed form, containing natural impurities such as hydrocarbons, resins, and free fatty acids that affect its color, odor, and melting behavior. The distinction between refined and crude wax centers on the level of processing and intended applications, influencing their physical characteristics and usability.

Defining Refined Wax: Properties and Characteristics

Refined wax is a purified form of wax obtained through processes such as distillation, filtration, and bleaching to remove impurities, colorants, and odors present in crude wax. It exhibits a higher melting point, consistent texture, and enhanced chemical stability, making it ideal for applications in cosmetics, pharmaceuticals, and food industries. Key characteristics include improved whiteness, lower acid value, and reduced sulfur content, distinguishing it from the raw and unprocessed nature of crude wax.

Understanding Crude Wax: Composition and Features

Crude wax consists primarily of a mixture of hydrocarbons, fatty acids, esters, and alcohols, which vary depending on the source such as mineral, plant, or animal origin. Its complex composition includes impurities like resins, pigments, and moisture, affecting its color, hardness, and melting point. Understanding these characteristics is essential for refining processes that enhance purity, consistency, and performance in industrial applications.

Key Differences Between Refined and Crude Wax

Refined wax undergoes extensive processing to remove impurities such as sulfur, colorants, and odors, resulting in a cleaner, more consistent product compared to crude wax. Crude wax typically retains natural contaminants and exhibits variable color and texture, affecting its performance and suitability for sensitive applications. The differences in purity and physical properties directly impact their applications, with refined wax preferred in cosmetics and pharmaceuticals, while crude wax is commonly used in industrial and agricultural settings.

Common Applications of Refined Wax

Refined wax offers superior purity and consistency, making it ideal for applications in cosmetics, pharmaceuticals, and food industries where safety and quality are critical. It is commonly used in candle making, coatings, and polishes due to its enhanced melting point and odorless characteristics. Crude wax, by contrast, is often reserved for industrial uses such as lubrication and waterproofing where refinement is less crucial.

Industrial Uses of Crude Wax

Crude wax, often derived from petroleum refining processes, finds extensive industrial applications due to its high melting point and natural impurities that enhance performance characteristics in coatings, rubber additives, and adhesives. Unlike refined wax, its impurities contribute to increased tackiness and better adhesion properties, making it valuable in manufacturing processes requiring durability and flexibility. Industrial sectors utilize crude wax for producing molded products, corrosion inhibitors, and as a binder in ceramics, exploiting its cost-effectiveness and functional versatility.

Refining Processes: From Crude to Refined Wax

Crude wax undergoes multiple refining processes including dewaxing, filtration, and bleaching to remove impurities such as oils, resins, and color bodies, resulting in a purer, more stable refined wax. The dewaxing process uses solvents or chilling techniques to separate wax from unwanted hydrocarbons, enhancing the wax's melting point and hardness. Advanced refining also improves the wax's clarity, odor, and performance, making it suitable for applications in cosmetics, candles, and pharmaceuticals.

Environmental Impact: Refined vs Crude Wax

Refined wax undergoes extensive processing to remove impurities, resulting in lower levels of toxic contaminants and reduced environmental pollution during its production and disposal compared to crude wax. Crude wax, often containing residual hydrocarbons and sulfur compounds, poses higher risks of soil and water contamination due to incomplete purification. The selection of refined wax supports sustainable practices by minimizing ecological harm and ensuring safer degradation or recycling processes.

Cost Comparison: Refined Wax vs Crude Wax

Refined wax typically incurs higher production costs due to extensive purification processes, resulting in a more consistent and high-quality product. Crude wax is less expensive because it requires minimal processing, making it a cost-effective option for industrial applications with lower quality demands. Businesses must balance the higher price of refined wax against its superior performance and purity when comparing procurement expenses.

Choosing the Right Wax for Your Product

Refined wax undergoes extensive purification to remove impurities, resulting in higher consistency, better color, and enhanced performance ideal for cosmetics, pharmaceuticals, and food packaging. Crude wax retains natural impurities and aromatic compounds, offering cost-effective applications in industrial uses and raw material processing. Selecting the right wax depends on product requirements for purity, texture, and regulatory standards specific to industries like cosmetics, candles, and coatings.

Refined Wax vs Crude Wax Infographic

materialdif.com

materialdif.com