Hydrogenated wax is produced by adding hydrogen to unsaturated waxes, resulting in a more stable, solid form with higher melting points ideal for industrial applications. Non-hydrogenated wax retains its natural unsaturated properties, making it softer, more flexible, and suitable for cosmetics and skincare products. The choice between hydrogenated and non-hydrogenated wax depends on the required texture, stability, and melting characteristics for specific uses.

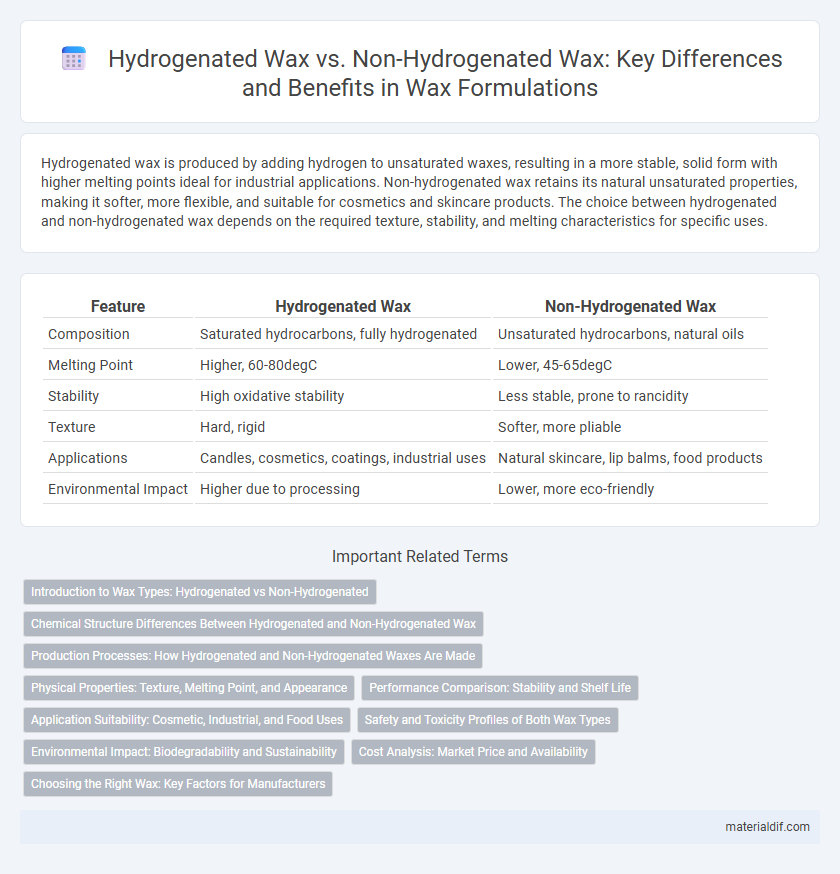

Table of Comparison

| Feature | Hydrogenated Wax | Non-Hydrogenated Wax |

|---|---|---|

| Composition | Saturated hydrocarbons, fully hydrogenated | Unsaturated hydrocarbons, natural oils |

| Melting Point | Higher, 60-80degC | Lower, 45-65degC |

| Stability | High oxidative stability | Less stable, prone to rancidity |

| Texture | Hard, rigid | Softer, more pliable |

| Applications | Candles, cosmetics, coatings, industrial uses | Natural skincare, lip balms, food products |

| Environmental Impact | Higher due to processing | Lower, more eco-friendly |

Introduction to Wax Types: Hydrogenated vs Non-Hydrogenated

Hydrogenated wax is chemically treated with hydrogen to increase its melting point, hardness, and stability, making it ideal for applications requiring durability and resistance to oxidation. Non-hydrogenated wax, retaining its natural unsaturated bonds, offers greater flexibility and a lower melting point, suitable for cosmetics and food products where softness and easy spreadability are desired. Understanding the differences between hydrogenated and non-hydrogenated waxes is crucial for selecting the right type based on performance requirements in manufacturing and formulation.

Chemical Structure Differences Between Hydrogenated and Non-Hydrogenated Wax

Hydrogenated wax contains saturated hydrocarbons formed by the addition of hydrogen atoms to unsaturated bonds, resulting in a more stable, solid structure at room temperature. Non-hydrogenated wax retains unsaturated carbon-carbon double bonds in its chemical structure, making it softer and more prone to oxidation. The key chemical difference lies in the saturation level, affecting physical properties such as melting point and oxidative stability.

Production Processes: How Hydrogenated and Non-Hydrogenated Waxes Are Made

Hydrogenated wax is produced through the chemical process of hydrogenation, where unsaturated hydrocarbons are exposed to hydrogen gas under high pressure and temperature in the presence of a catalyst, converting double bonds into single bonds and increasing the wax's stability and melting point. Non-hydrogenated wax, on the other hand, is extracted and purified directly from natural sources like plants, animals, or petroleum without altering its chemical structure, retaining more of the original unsaturated compounds. The production process of hydrogenated wax results in a harder, less reactive material suited for applications requiring durability, whereas non-hydrogenated waxes maintain softer textures and pliability useful in cosmetics and food coatings.

Physical Properties: Texture, Melting Point, and Appearance

Hydrogenated wax exhibits a harder texture, higher melting point, and clearer appearance due to the saturation of carbon bonds which increase structural stability. Non-hydrogenated wax tends to be softer, with a lower melting point and a more opaque or yellowish hue, resulting from the presence of unsaturated bonds. These physical differences influence their application in cosmetics, food coatings, and candles, where specific melting behaviors and textures are crucial.

Performance Comparison: Stability and Shelf Life

Hydrogenated wax offers superior stability and a longer shelf life compared to non-hydrogenated wax, due to its fully saturated molecular structure that resists oxidation and rancidity. Non-hydrogenated wax, containing unsaturated bonds, is more prone to degradation when exposed to heat, light, and oxygen, resulting in a shorter shelf life. This enhanced oxidative stability makes hydrogenated wax ideal for applications requiring extended durability and consistent performance.

Application Suitability: Cosmetic, Industrial, and Food Uses

Hydrogenated wax offers a higher melting point and greater stability, making it ideal for industrial applications such as lubricants, coatings, and candles. Non-hydrogenated wax, with its softer texture and natural composition, suits cosmetic uses like lip balms, creams, and hair products due to better skin compatibility. In food applications, non-hydrogenated waxes are preferred for coating fruits and confectionery, while hydrogenated wax is used in packaging and food-grade coatings requiring durability.

Safety and Toxicity Profiles of Both Wax Types

Hydrogenated waxes, produced through the hydrogenation process, typically exhibit greater chemical stability and lower reactivity, reducing the risk of oxidative degradation and associated toxic byproducts compared to non-hydrogenated waxes. Non-hydrogenated waxes may contain unsaturated compounds prone to oxidation, potentially generating harmful free radicals or allergenic substances, which raises concerns in cosmetic and food applications. Safety assessments highlight that hydrogenated waxes generally have a more favorable toxicity profile with less potential for skin irritation or sensitization, making them preferable in formulations requiring high purity and long-term stability.

Environmental Impact: Biodegradability and Sustainability

Hydrogenated waxes, derived from petroleum or palm oil, tend to have lower biodegradability and contribute more significantly to environmental pollution compared to non-hydrogenated waxes, which are often plant-based and break down more easily in natural ecosystems. Non-hydrogenated waxes, such as those sourced from beeswax or carnauba, offer enhanced sustainability due to their renewable origins and reduced carbon footprint. Choosing non-hydrogenated waxes supports circular economy principles by minimizing synthetic chemical processing and promoting compostability.

Cost Analysis: Market Price and Availability

Hydrogenated wax generally has a higher market price compared to non-hydrogenated wax due to its more complex processing requirements and enhanced stability. Non-hydrogenated wax is more widely available and cost-effective, making it a preferred choice for industries focused on budget constraints. Market fluctuations in raw material supply and production technology advancements also influence the cost dynamics between these two wax types.

Choosing the Right Wax: Key Factors for Manufacturers

Manufacturers selecting between hydrogenated and non-hydrogenated wax should consider factors such as melting point, stability, and application requirements. Hydrogenated wax offers higher oxidative stability and a firmer texture ideal for cosmetics and food coatings, while non-hydrogenated wax retains more natural properties suitable for organic and biodegradable products. Evaluating product shelf life, environmental impact, and regulatory compliance ensures the optimal wax choice aligns with manufacturing goals.

Hydrogenated Wax vs Non-Hydrogenated Wax Infographic

materialdif.com

materialdif.com