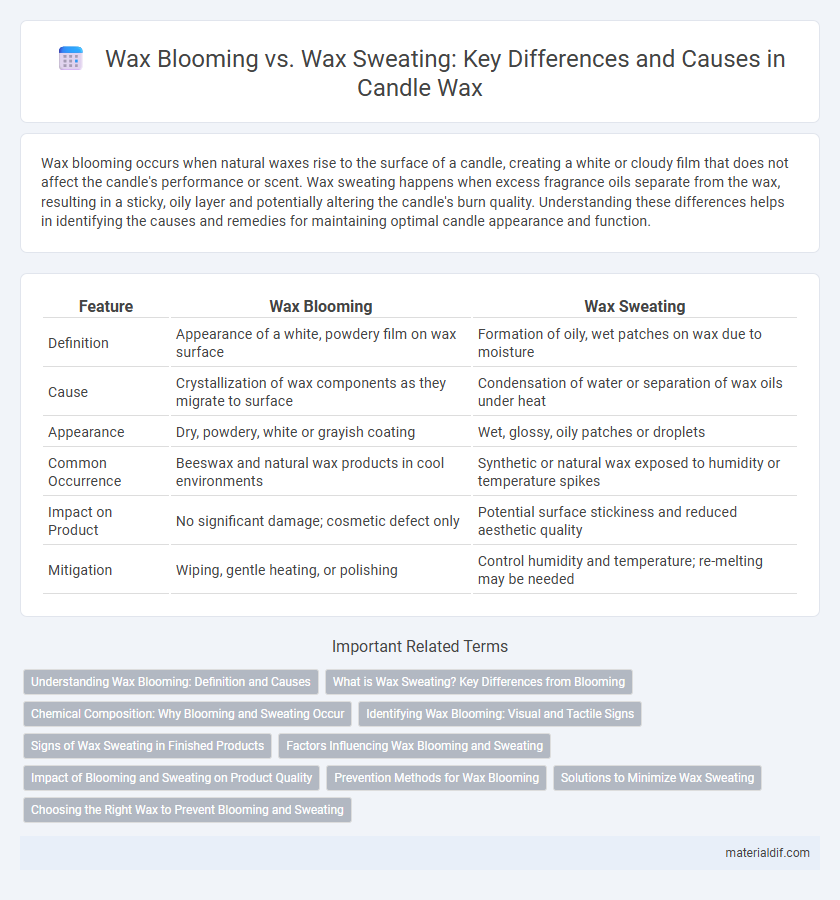

Wax blooming occurs when natural waxes rise to the surface of a candle, creating a white or cloudy film that does not affect the candle's performance or scent. Wax sweating happens when excess fragrance oils separate from the wax, resulting in a sticky, oily layer and potentially altering the candle's burn quality. Understanding these differences helps in identifying the causes and remedies for maintaining optimal candle appearance and function.

Table of Comparison

| Feature | Wax Blooming | Wax Sweating |

|---|---|---|

| Definition | Appearance of a white, powdery film on wax surface | Formation of oily, wet patches on wax due to moisture |

| Cause | Crystallization of wax components as they migrate to surface | Condensation of water or separation of wax oils under heat |

| Appearance | Dry, powdery, white or grayish coating | Wet, glossy, oily patches or droplets |

| Common Occurrence | Beeswax and natural wax products in cool environments | Synthetic or natural wax exposed to humidity or temperature spikes |

| Impact on Product | No significant damage; cosmetic defect only | Potential surface stickiness and reduced aesthetic quality |

| Mitigation | Wiping, gentle heating, or polishing | Control humidity and temperature; re-melting may be needed |

Understanding Wax Blooming: Definition and Causes

Wax blooming refers to the formation of a whitish or cloudy layer on the surface of wax products, caused by the migration of crystallized wax compounds to the surface. This phenomenon typically occurs when wax is exposed to fluctuating temperatures or improper cooling, leading to uneven crystallization. Understanding these causes helps in controlling appearance issues in candles, cosmetics, and other wax-based materials.

What is Wax Sweating? Key Differences from Blooming

Wax sweating occurs when moisture condenses on the surface of a wax product, creating a wet, sticky layer, whereas wax blooming is the formation of a powdery or cloudy white film caused by the migration of wax constituents to the surface. Sweating is typically due to temperature fluctuations or high humidity, whereas blooming results from the crystallization and recrystallization of wax components. Understanding these differences is crucial for maintaining the appearance and longevity of waxed surfaces and products.

Chemical Composition: Why Blooming and Sweating Occur

Wax blooming occurs when specific long-chain hydrocarbons and esters within the wax migrate to the surface and crystallize, forming a white or hazy layer due to phase separation. Wax sweating happens as volatile components or impurities evaporate or condense, causing moisture to accumulate and create a wet, translucent film. The chemical composition, including the ratio of lipids, esters, and aromatic compounds, dictates the propensity for either blooming or sweating during temperature fluctuations.

Identifying Wax Blooming: Visual and Tactile Signs

Wax blooming appears as a fine, powdery white film on the surface of wax, often caused by oxidation or environmental factors. Visually, it looks like a slight haze or frost, while tactilely it feels dry and powdery to the touch. Unlike wax sweating, which is oily and sticky, blooming does not alter the wax's texture beyond this surface layer.

Signs of Wax Sweating in Finished Products

Signs of wax sweating in finished products include a greasy or oily residue on the surface, often accompanied by a dull or sticky appearance. Unlike wax blooming, which manifests as white, powdery crystals, sweating causes visible liquid droplets or a moist film to form. This condition results from excess oils or additives migrating to the surface, affecting product texture and appearance.

Factors Influencing Wax Blooming and Sweating

Wax blooming occurs due to the migration of low molecular weight components to the surface, influenced by temperature fluctuations and storage conditions. Wax sweating results from moisture condensation on the wax surface, often triggered by rapid changes in humidity and ambient temperature. Both phenomena depend heavily on wax composition, additives, and environmental stability to minimize surface defects.

Impact of Blooming and Sweating on Product Quality

Wax blooming creates a white, powdery surface layer caused by the migration of wax components to the exterior, potentially diminishing the visual appeal but often protecting the product's interior from oxidation. Sweating results from heat-induced melting and re-distribution of wax, leading to a sticky, glossy surface that can compromise integrity and promote contamination. Both phenomena affect product quality by altering texture, appearance, and shelf-life stability, with blooming generally being reversible and less damaging than sweating.

Prevention Methods for Wax Blooming

Wax blooming occurs when wax migrates to the surface, forming a white, powdery film, while wax sweating is caused by trapped moisture and heat causing droplets on the surface. Prevention methods for wax blooming include maintaining proper storage temperatures between 18-24degC (65-75degF), avoiding exposure to direct sunlight, and using additives or blending waxes that reduce migration of low melting components. Controlling cooling rates during wax processing and ensuring proper curing time also significantly minimize the risk of wax bloom formation.

Solutions to Minimize Wax Sweating

Wax sweating occurs when excess oils within the candle migrate to the surface, causing a greasy film, while wax blooming manifests as a white, powdery residue due to crystallization of wax components. To minimize wax sweating, maintain consistent, moderate room temperatures and avoid placing candles near heat sources or direct sunlight. Using cosmetics-grade fragrances and thoroughly blending wax with additives like Vybar can improve wax stability and reduce oil separation.

Choosing the Right Wax to Prevent Blooming and Sweating

Selecting a wax with a low melting point and stable formulation is crucial to prevent blooming and sweating, common issues caused by temperature fluctuations and incompatible ingredients. Wax blooming, characterized by a powdery surface haze, results from fat or oil migration, while sweating involves liquid droplets appearing on the surface due to excessive heat. Opting for high-quality synthetic or natural wax blends designed for specific climates reduces the risk of these defects, ensuring a smooth, clean finish.

Wax blooming vs Wax sweating Infographic

materialdif.com

materialdif.com