Slack wax is a semi-refined intermediate product containing impurities such as oil and resin, commonly used as a raw material for further refining in various industries. Fully refined wax undergoes extensive purification, resulting in a product with higher melting points, better clarity, and improved performance for applications like cosmetics, candles, and coatings. Selecting between slack wax and fully refined wax depends on the desired quality and end-use specifications.

Table of Comparison

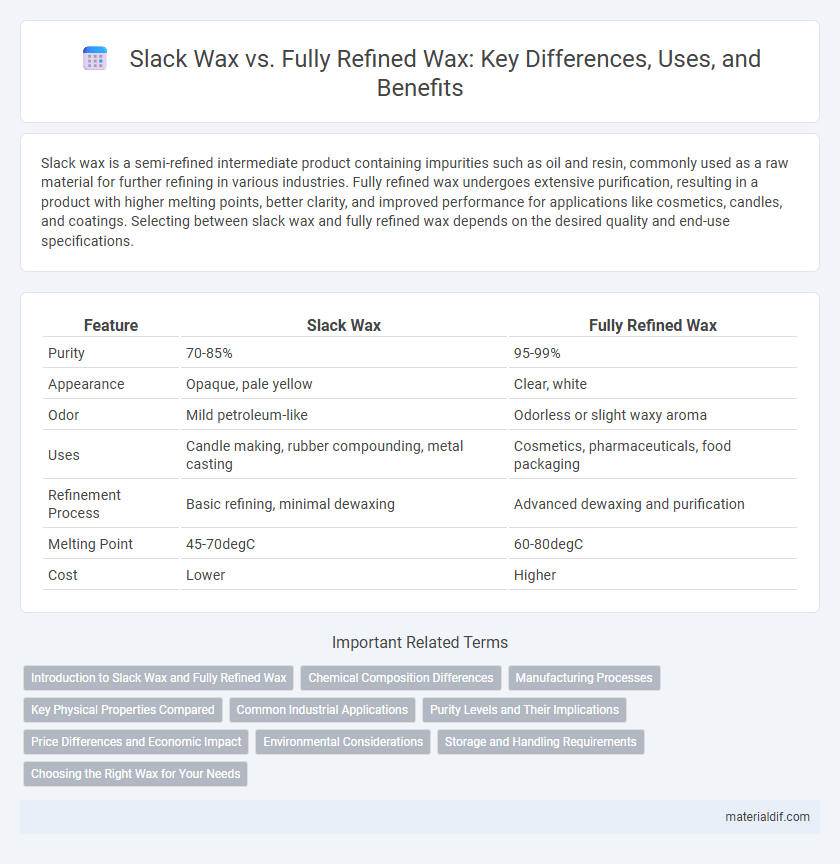

| Feature | Slack Wax | Fully Refined Wax |

|---|---|---|

| Purity | 70-85% | 95-99% |

| Appearance | Opaque, pale yellow | Clear, white |

| Odor | Mild petroleum-like | Odorless or slight waxy aroma |

| Uses | Candle making, rubber compounding, metal casting | Cosmetics, pharmaceuticals, food packaging |

| Refinement Process | Basic refining, minimal dewaxing | Advanced dewaxing and purification |

| Melting Point | 45-70degC | 60-80degC |

| Cost | Lower | Higher |

Introduction to Slack Wax and Fully Refined Wax

Slack wax is an intermediate product derived from the dewaxing of petroleum oils, containing both oil and wax components with a typical oil content ranging from 10% to 30%. Fully refined wax undergoes further processing to remove oil traces, resulting in a purer wax with an oil content below 0.5%, ideal for applications requiring high melting points and minimal oil contamination. The distinction between slack wax and fully refined wax lies primarily in their oil content and purity levels, influencing their suitability for various industrial and cosmetic uses.

Chemical Composition Differences

Slack wax contains about 15-30% oil and is less refined, retaining more impurities such as hydrocarbons and paraffins. Fully refined wax undergoes additional processing to remove oils and contaminants, resulting in a higher purity level exceeding 99% hydrocarbons. The key chemical difference lies in the residual oil content and refining depth, affecting melting point, color, and application suitability.

Manufacturing Processes

Slack wax undergoes minimal refining, retaining more oil and impurities derived from residual petroleum processing, which results in a softer and less pure material. Fully refined wax is subjected to extensive filtration, de-oiling, and bleaching processes that remove all contaminants, producing a harder, more stable, and highly pure wax suitable for cosmetic and pharmaceutical applications. Manufacturing slack wax involves distillation and dewaxing of residual oils, whereas fully refined wax requires additional chemical treatments and refining steps to achieve superior quality.

Key Physical Properties Compared

Slack wax exhibits higher viscosity and contains more residual oil content compared to fully refined wax, affecting its melting point and consistency. Fully refined wax has a higher melting point, greater hardness, and superior color clarity, making it ideal for applications requiring purity and durability. The difference in oil content and refining process directly influences the thermal stability and mechanical strength of both wax types.

Common Industrial Applications

Slack wax, a partially refined petroleum wax containing residual oil, is commonly used in industrial applications such as rubber compounding, candle making, and adhesives, where softness and tackiness are beneficial. Fully refined wax, characterized by low oil content and higher purity, is preferred for applications demanding enhanced color, odor, and melting point control, including cosmetics, food packaging coatings, and high-quality polishes. The choice between slack wax and fully refined wax depends on specific industry requirements for performance, purity, and cost-effectiveness.

Purity Levels and Their Implications

Slack wax contains impurities such as oil and contaminants, resulting in a purity level typically between 65% to 90%, which affects its suitability for applications requiring higher refinement. Fully refined wax undergoes further processing to remove these impurities, achieving purity levels above 99%, making it ideal for cosmetics, pharmaceuticals, and high-quality candles. The higher purity of fully refined wax ensures better performance, smoother texture, and consistent melting points, crucial for sensitive and precise uses.

Price Differences and Economic Impact

Slack wax, a semi-refined petroleum wax, is generally priced lower than fully refined wax due to less intensive processing and higher impurity levels. Fully refined wax commands a premium price reflecting its superior purity, consistent quality, and enhanced performance in applications such as cosmetics and pharmaceuticals. The economic impact favors slack wax for bulk industrial uses where cost-efficiency is critical, while fully refined wax supports higher-value markets demanding stringent product specifications.

Environmental Considerations

Slack wax derives from petroleum refining and contains residual impurities that can pose environmental hazards during production and disposal. Fully refined wax undergoes extensive purification, reducing contaminants and minimizing ecological impact through cleaner manufacturing processes. Choosing fully refined wax supports sustainability by limiting toxic emissions and promoting biodegradability in wax applications.

Storage and Handling Requirements

Slack wax requires controlled storage conditions to prevent oxidation and contamination, typically kept in airtight containers at stable temperatures to maintain its semi-solid state. Fully refined wax offers greater stability and can be stored under less stringent conditions without significant degradation, making it easier to handle during production and transportation. Proper handling of slack wax involves avoiding exposure to moisture and air, while fully refined wax's higher purity reduces such risks.

Choosing the Right Wax for Your Needs

Choosing between Slack Wax and Fully Refined Wax depends on your specific application and purity requirements. Slack Wax contains higher oil content and is less processed, making it ideal for uses needing flexibility and adhesion, such as candles and packaging. Fully Refined Wax offers higher purity with minimal impurities, preferred in cosmetics, pharmaceuticals, and food-grade applications where color and odor control are critical.

Slack Wax vs Fully Refined Wax Infographic

materialdif.com

materialdif.com