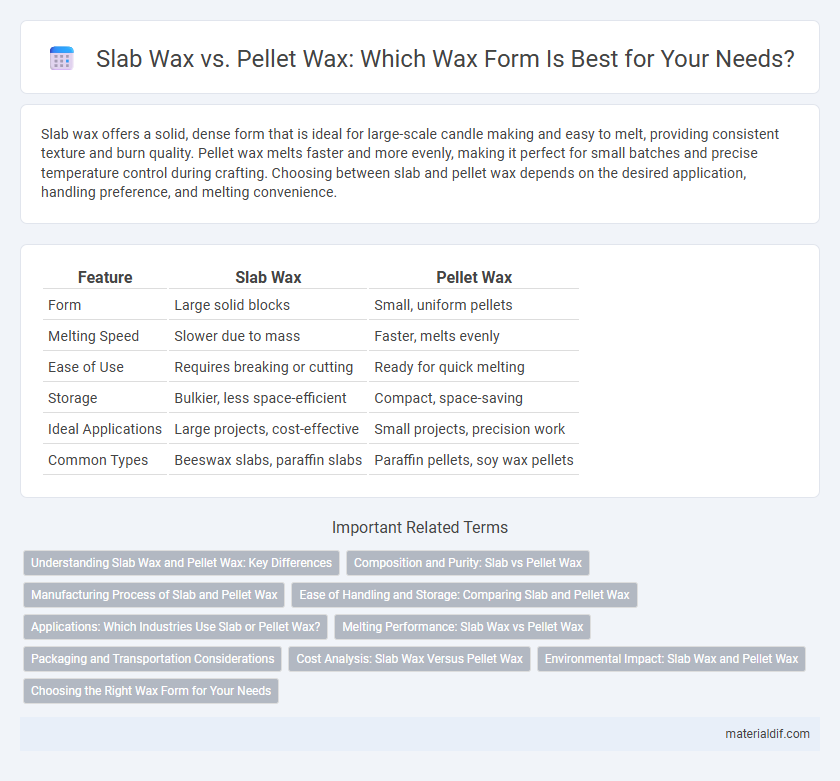

Slab wax offers a solid, dense form that is ideal for large-scale candle making and easy to melt, providing consistent texture and burn quality. Pellet wax melts faster and more evenly, making it perfect for small batches and precise temperature control during crafting. Choosing between slab and pellet wax depends on the desired application, handling preference, and melting convenience.

Table of Comparison

| Feature | Slab Wax | Pellet Wax |

|---|---|---|

| Form | Large solid blocks | Small, uniform pellets |

| Melting Speed | Slower due to mass | Faster, melts evenly |

| Ease of Use | Requires breaking or cutting | Ready for quick melting |

| Storage | Bulkier, less space-efficient | Compact, space-saving |

| Ideal Applications | Large projects, cost-effective | Small projects, precision work |

| Common Types | Beeswax slabs, paraffin slabs | Paraffin pellets, soy wax pellets |

Understanding Slab Wax and Pellet Wax: Key Differences

Slab wax consists of large, solid blocks that require cutting or melting, offering precise control for various applications such as candle making and cosmetics. Pellet wax is made up of small, uniform beads designed for easy melting and consistent blending, ideal for hobbyists and industrial use. Key differences include ease of handling, melting consistency, and application versatility, making each type suitable for specific user needs.

Composition and Purity: Slab vs Pellet Wax

Slab wax typically consists of a higher concentration of pure paraffin, offering a dense and uniform composition ideal for long-lasting applications. Pellet wax is often a blend of paraffin and microcrystalline waxes, resulting in smaller particles that melt uniformly but may contain more additives. The purity of slab wax generally surpasses pellet wax due to fewer processing steps, influencing both melting point and scent retention.

Manufacturing Process of Slab and Pellet Wax

Slab wax is produced by cooling molten wax into large, solid blocks that are then cut into slabs, ensuring a dense and uniform texture ideal for various industrial applications. Pellet wax undergoes an additional cooling and extrusion process, where molten wax is passed through a die and solidified into small, uniform pellets for easier handling and precise dosing in manufacturing. The pelletizing process enhances melting efficiency and reduces waste, making pellet wax preferable in automated production lines.

Ease of Handling and Storage: Comparing Slab and Pellet Wax

Slab wax offers straightforward handling due to its solid, uniform shape, making it easier to cut and portion for precise use. Pellet wax provides enhanced convenience in measuring and melting, as the small, consistent granules melt quickly and evenly, reducing waste. Storage-wise, slab wax requires more space and careful stacking to avoid breakage, while pellet wax packs densely and resists clumping, ensuring prolonged usability and efficient storage.

Applications: Which Industries Use Slab or Pellet Wax?

Slab wax is commonly used in industries requiring bulk melting and molding processes, such as candle making, cosmetics, and pharmaceuticals, due to its large, solid form that facilitates controlled melting. Pellet wax, favored in packaging, food coatings, and personal care products, offers easy handling and uniform melting because of its small, consistent granules. Both types cater to different manufacturing needs, with slab wax ideal for large-scale production and pellet wax suited for precise blending and dosing applications.

Melting Performance: Slab Wax vs Pellet Wax

Slab wax offers a slower, more controlled melting process ideal for large batches, maintaining uniform heat distribution and reducing the risk of overheating. Pellet wax melts faster and more evenly due to its small, consistent size, making it highly efficient for quick melting and precise temperature control. Comparing melting performance, pellet wax delivers superior speed and consistency, while slab wax provides stability for extended heating periods.

Packaging and Transportation Considerations

Slab wax typically comes in large, solid blocks, which require more robust packaging to prevent damage during transportation and can be heavier to handle, impacting shipping costs. Pellet wax is packaged in smaller, more uniform granules, often in resealable bags or boxes, offering easier handling, efficient storage, and reduced risk of contamination. The compact and lightweight nature of pellet wax packaging makes it more cost-effective for shipping and convenient for inventory management.

Cost Analysis: Slab Wax Versus Pellet Wax

Slab wax typically offers a lower cost per pound compared to pellet wax due to minimal processing requirements and bulk packaging, making it a budget-friendly option for large-scale candle production. Pellet wax, while generally more expensive, provides consistent melting properties and ease of handling that can reduce labor costs and waste in manufacturing processes. Evaluating total production expenses, including labor and material waste, is crucial for determining whether slab wax or pellet wax presents better cost efficiency for specific candle-making needs.

Environmental Impact: Slab Wax and Pellet Wax

Slab wax typically generates more waste due to irregular melting and trimming during use, increasing environmental burden compared to pellet wax, which melts uniformly and minimizes excess residue. Pellet wax is often made from biodegradable or renewable materials, enhancing its eco-friendly profile relative to some slab wax variants derived from petroleum-based sources. The controlled melting properties of pellet wax contribute to energy efficiency and reduced emissions during processing, supporting greener manufacturing practices.

Choosing the Right Wax Form for Your Needs

Slab wax offers a solid, easy-to-mold option ideal for customized shapes and precise applications, providing firm texture control for professional use. Pellet wax melts quickly and evenly, making it perfect for large-scale projects and consistent pouring in candle making or cosmetics. Selecting between slab and pellet wax depends on your project's scale, melting equipment, and desired ease of handling to achieve optimal results.

Slab wax vs Pellet wax Infographic

materialdif.com

materialdif.com