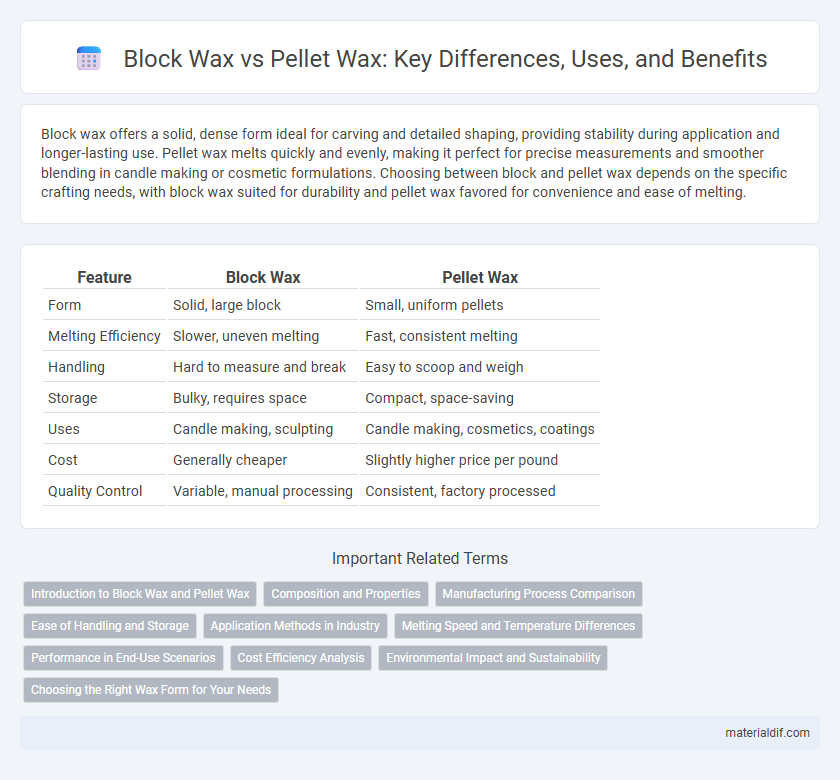

Block wax offers a solid, dense form ideal for carving and detailed shaping, providing stability during application and longer-lasting use. Pellet wax melts quickly and evenly, making it perfect for precise measurements and smoother blending in candle making or cosmetic formulations. Choosing between block and pellet wax depends on the specific crafting needs, with block wax suited for durability and pellet wax favored for convenience and ease of melting.

Table of Comparison

| Feature | Block Wax | Pellet Wax |

|---|---|---|

| Form | Solid, large block | Small, uniform pellets |

| Melting Efficiency | Slower, uneven melting | Fast, consistent melting |

| Handling | Hard to measure and break | Easy to scoop and weigh |

| Storage | Bulky, requires space | Compact, space-saving |

| Uses | Candle making, sculpting | Candle making, cosmetics, coatings |

| Cost | Generally cheaper | Slightly higher price per pound |

| Quality Control | Variable, manual processing | Consistent, factory processed |

Introduction to Block Wax and Pellet Wax

Block wax is a solid form of wax commonly used in candle making and cosmetics, offering easy handling and versatility due to its dense, compact shape. Pellet wax consists of small, uniform beads that melt quickly and evenly, ideal for precise temperature control in crafting and industrial applications. Both types vary in composition and melting points, influencing their suitability for specific projects and performance requirements.

Composition and Properties

Block wax typically consists of a denser, more solid composition containing high molecular weight hydrocarbons, which results in a harder texture and higher melting point ideal for durable applications. Pellet wax features smaller, uniform granules with a refined blend of paraffin and microcrystalline waxes, offering improved flexibility, faster melting rates, and easier handling in industrial processes. The differences in their composition directly influence thermal properties, hardness, and compatibility with additives in manufacturing and cosmetic uses.

Manufacturing Process Comparison

Block wax is produced by pouring molten wax into large molds where it solidifies into dense, uniform blocks, ensuring consistent texture and minimal air pockets. Pellet wax manufacturing involves cooling molten wax on chilled rollers followed by mechanical cutting into small, uniform pellets that facilitate easier melting and faster processing. The block wax process emphasizes bulk handling and storage efficiency, while pellet wax manufacturing prioritizes rapid melting and dosing precision in industrial applications.

Ease of Handling and Storage

Block wax offers straightforward handling due to its solid form, allowing for easy cutting and measurement, while pellet wax enhances convenience through uniform, small pieces that melt consistently. Pellet wax typically requires less storage space as it can be densely packed, whereas block wax demands more room and careful stacking to prevent damage. Both forms provide efficient options, but pellet wax improves operational flow with minimal preparation and simpler storage solutions.

Application Methods in Industry

Block wax is predominantly used in industrial applications requiring slow melting and precise molding, such as candle making and encaustic art, due to its solid, compact form that allows for easy handling and long-lasting burn. Pellet wax, composed of small, uniform pieces, facilitates faster melting and consistent heating, making it ideal for automated pouring systems in large-scale candle production and cosmetics manufacturing. The choice between block and pellet wax depends on the required melting rate, ease of handling, and compatibility with the specific industrial equipment used in production.

Melting Speed and Temperature Differences

Block wax typically has a slower melting speed due to its dense and solid form, which requires more heat energy to reach the melting point compared to pellet wax. Pellet wax melts at a lower temperature and faster rate because its small, uniform granules increase surface area exposure to heat, enabling quicker liquefaction. These differences make pellet wax more suitable for applications demanding rapid melting, while block wax is preferred for longer, controlled melting processes.

Performance in End-Use Scenarios

Block wax offers superior moldability and consistent density, making it ideal for detailed candle designs and sculpting applications. Pellet wax melts faster and provides easier measurement and blending, enhancing efficiency in mass production and container filling. Both forms exhibit strong scent throw and smooth finish, but selection depends on whether precision or processing speed is prioritized in the end-use scenario.

Cost Efficiency Analysis

Block wax generally offers greater cost efficiency due to its lower price per pound and reduced packaging expenses compared to pellet wax. Pellet wax typically commands a higher price because of its ease of handling and melting speed, which can reduce labor costs in industrial applications. When evaluating overall cost efficiency, block wax is more economical for large-scale production, while pellet wax suits small to medium operations seeking convenience.

Environmental Impact and Sustainability

Block wax typically has a lower environmental impact compared to pellet wax due to its simpler manufacturing process, which consumes less energy and produces fewer emissions. Pellet wax often requires additional processing and packaging, contributing to increased resource use and waste generation. Choosing sustainably sourced block wax can further enhance environmental benefits by promoting biodegradable and non-toxic materials.

Choosing the Right Wax Form for Your Needs

Block wax offers a dense and solid form ideal for sculpting, carving, or creating large molds, providing stability and longer burn time; pellet wax melts faster and distributes more evenly, making it suitable for candle making and small-scale projects. Consider the specific application, desired melting speed, and ease of handling when choosing between block and pellet wax. Selecting the appropriate wax form enhances efficiency and quality in crafting, ensuring optimal results for both hobbyists and professionals.

Block Wax vs Pellet Wax Infographic

materialdif.com

materialdif.com