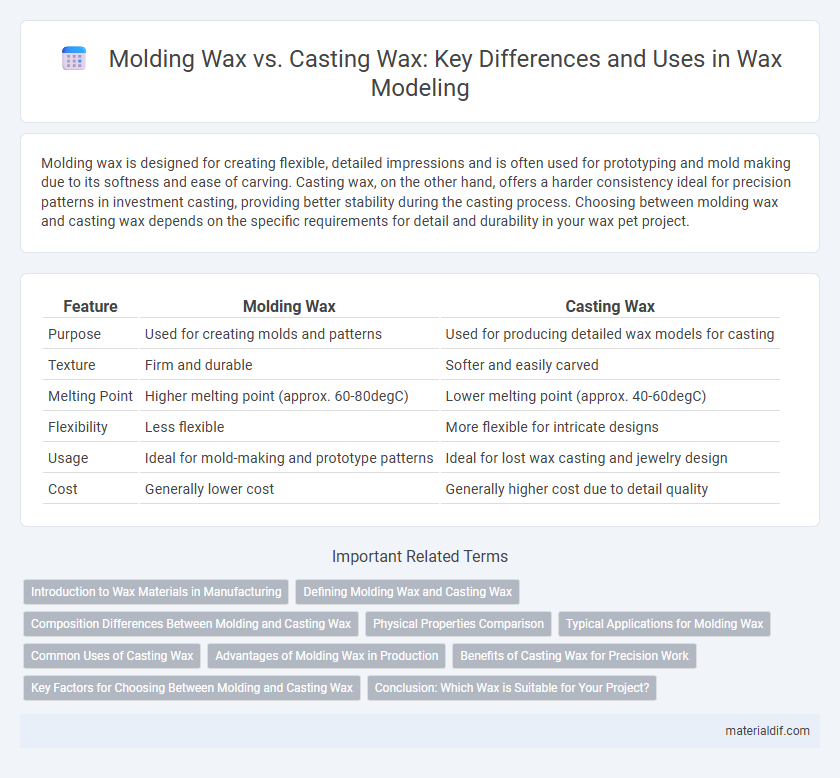

Molding wax is designed for creating flexible, detailed impressions and is often used for prototyping and mold making due to its softness and ease of carving. Casting wax, on the other hand, offers a harder consistency ideal for precision patterns in investment casting, providing better stability during the casting process. Choosing between molding wax and casting wax depends on the specific requirements for detail and durability in your wax pet project.

Table of Comparison

| Feature | Molding Wax | Casting Wax |

|---|---|---|

| Purpose | Used for creating molds and patterns | Used for producing detailed wax models for casting |

| Texture | Firm and durable | Softer and easily carved |

| Melting Point | Higher melting point (approx. 60-80degC) | Lower melting point (approx. 40-60degC) |

| Flexibility | Less flexible | More flexible for intricate designs |

| Usage | Ideal for mold-making and prototype patterns | Ideal for lost wax casting and jewelry design |

| Cost | Generally lower cost | Generally higher cost due to detail quality |

Introduction to Wax Materials in Manufacturing

Molding wax and casting wax serve distinct purposes in manufacturing, with molding wax designed for creating precise molds due to its pliability and ease of shaping. Casting wax, often utilized in lost-wax casting processes, offers higher detail resolution and burns out cleanly to produce intricate metal parts. Understanding the properties and applications of these wax materials is essential for optimizing production workflows in industries such as jewelry, aerospace, and automotive manufacturing.

Defining Molding Wax and Casting Wax

Molding wax is a pliable substance specifically designed to create detailed impressions or molds for various applications such as jewelry or industrial prototyping, characterized by its softness and ease of shaping. Casting wax, on the other hand, is formulated to burn out cleanly without residue during the lost-wax casting process, enabling the production of precise metal parts or sculptures. Both wax types serve crucial roles in manufacturing and art, with molding wax emphasizing mold creation and casting wax facilitating the transition from wax model to metal object.

Composition Differences Between Molding and Casting Wax

Molding wax typically contains a blend of paraffin and microcrystalline waxes, offering flexibility and ease of shaping, while casting wax is primarily formulated from harder, high-melting-point waxes to withstand the high temperatures of metal casting. The composition differences influence properties such as melting point, pliability, and burnout behavior, with casting wax designed for precise burnout and minimal residue during the lost-wax casting process. Understanding these compositional variations is crucial for selecting the appropriate wax type in jewelry-making and industrial applications.

Physical Properties Comparison

Molding wax exhibits higher hardness and lower thermal expansion compared to casting wax, making it ideal for creating precise molds with minimal deformation under heat. Casting wax has a lower melting point and greater flexibility, allowing it to flow easily into intricate mold cavities during the casting process. Both wax types differ significantly in viscosity and tensile strength, impacting their performance in various fabrication techniques.

Typical Applications for Molding Wax

Molding wax is typically used in applications such as creating detailed patterns for jewelry making, dental models, and small-scale prototyping due to its excellent carving properties and ability to hold fine details. Unlike casting wax, which is designed to be melted and poured into molds for metal casting, molding wax provides a stable medium for shaping and sculpting intricate designs. It is favored in industries where precision and smooth surface finish are crucial for producing accurate molds.

Common Uses of Casting Wax

Casting wax is widely used in jewelry making and dental applications due to its precise melting point and fine detail reproduction. It allows artisans to create intricate patterns that are essential for investment casting processes. Common uses include producing detailed prototypes, molds for metal casting, and components requiring high accuracy.

Advantages of Molding Wax in Production

Molding wax offers superior surface detail replication and higher dimensional stability compared to casting wax, making it ideal for precise production processes. Its excellent melting behavior reduces deformation risks during molding, ensuring consistent product quality. This wax type also provides enhanced rigidity, facilitating easier handling and faster cycle times in manufacturing environments.

Benefits of Casting Wax for Precision Work

Casting wax offers superior dimensional stability and fine detail reproduction, making it ideal for precision work in jewelry and dental applications. Its uniform texture allows for smoother surfaces and intricate designs that are difficult to achieve with molding wax. This precision directly enhances the quality and accuracy of the final cast product.

Key Factors for Choosing Between Molding and Casting Wax

Molding wax offers superior detail reproduction and is ideal for creating intricate patterns, while casting wax provides better heat resistance suited for investment casting processes. Key factors influencing the choice between molding and casting wax include thermal properties, ease of carving, and wax hardness. Selecting the appropriate wax depends on the complexity of the design and the specific requirements of the casting method.

Conclusion: Which Wax is Suitable for Your Project?

Molding wax offers precise shaping capabilities ideal for creating detailed impressions and prototypes, while casting wax is formulated to burn out cleanly, making it essential for investment casting processes. Choose molding wax for projects requiring surface accuracy and flexibility, and opt for casting wax when the goal is to produce intricate metal castings with minimal residue. Understanding the specific manufacturing needs and end-use will determine the most suitable wax type for optimal results.

Molding Wax vs Casting Wax Infographic

materialdif.com

materialdif.com