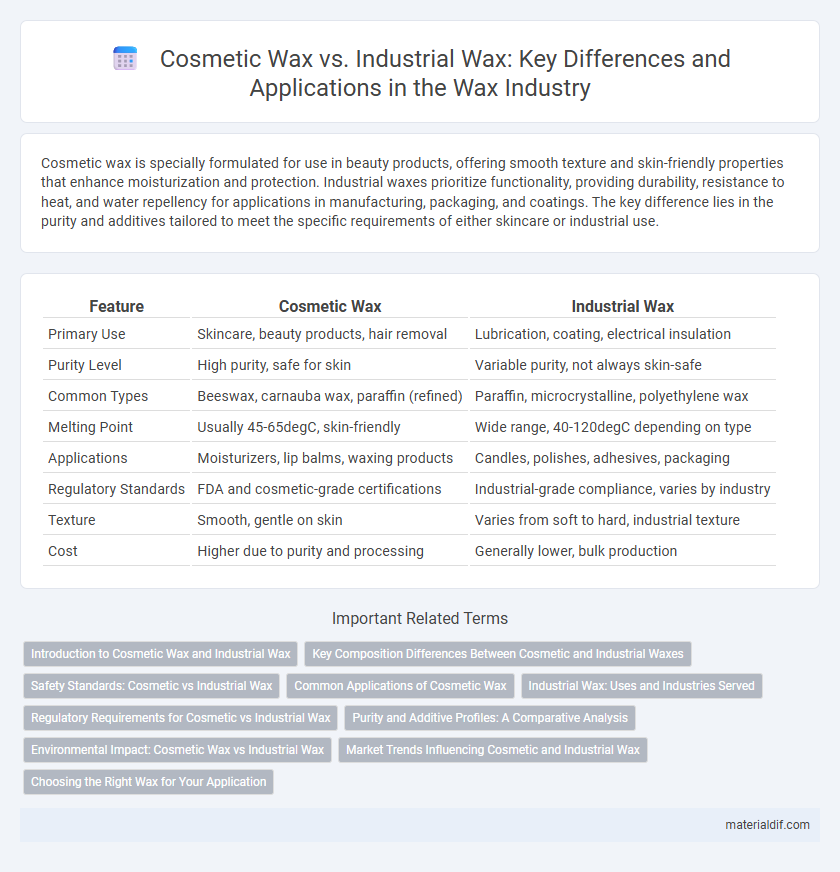

Cosmetic wax is specially formulated for use in beauty products, offering smooth texture and skin-friendly properties that enhance moisturization and protection. Industrial waxes prioritize functionality, providing durability, resistance to heat, and water repellency for applications in manufacturing, packaging, and coatings. The key difference lies in the purity and additives tailored to meet the specific requirements of either skincare or industrial use.

Table of Comparison

| Feature | Cosmetic Wax | Industrial Wax |

|---|---|---|

| Primary Use | Skincare, beauty products, hair removal | Lubrication, coating, electrical insulation |

| Purity Level | High purity, safe for skin | Variable purity, not always skin-safe |

| Common Types | Beeswax, carnauba wax, paraffin (refined) | Paraffin, microcrystalline, polyethylene wax |

| Melting Point | Usually 45-65degC, skin-friendly | Wide range, 40-120degC depending on type |

| Applications | Moisturizers, lip balms, waxing products | Candles, polishes, adhesives, packaging |

| Regulatory Standards | FDA and cosmetic-grade certifications | Industrial-grade compliance, varies by industry |

| Texture | Smooth, gentle on skin | Varies from soft to hard, industrial texture |

| Cost | Higher due to purity and processing | Generally lower, bulk production |

Introduction to Cosmetic Wax and Industrial Wax

Cosmetic wax, derived from natural sources such as beeswax and carnauba, contains skin-friendly properties ideal for skincare and beauty products, offering texture, hydration, and emulsification benefits. Industrial waxes, including paraffin and microcrystalline wax, are typically petroleum-based and designed for durability, heat resistance, and lubrication in manufacturing and mechanical applications. The distinction lies in purity and formulation, with cosmetic waxes meeting safety standards for topical use, while industrial waxes prioritize functional performance in non-cosmetic contexts.

Key Composition Differences Between Cosmetic and Industrial Waxes

Cosmetic waxes primarily comprise natural ingredients such as beeswax, carnauba wax, and candelilla wax, valued for their skin-friendly properties and non-toxicity. Industrial waxes tend to contain synthetic components like paraffin, microcrystalline wax, and polyethylene wax, optimized for durability, heat resistance, and lubricity. The key composition difference lies in cosmetic waxes' emphasis on purity and hypoallergenic characteristics, whereas industrial waxes prioritize performance and functionality in manufacturing processes.

Safety Standards: Cosmetic vs Industrial Wax

Cosmetic wax adheres to strict safety standards set by regulatory agencies like the FDA and COSMOS, ensuring non-toxicity, hypoallergenic properties, and suitability for direct skin contact. Industrial wax, used in manufacturing or lubrication, follows different safety protocols centered on chemical stability and fire resistance but often contains additives unsuitable for personal care applications. Understanding these distinct safety requirements is essential for preventing adverse reactions and ensuring compliance in product formulation.

Common Applications of Cosmetic Wax

Cosmetic waxes are primarily used in skincare products, lip balms, and hair removal formulations due to their moisturizing and pliable properties. These waxes, such as beeswax and carnauba wax, provide texture, stability, and emollient benefits in creams, lotions, and makeup products. Unlike industrial waxes, which are applied in mechanical, automotive, and manufacturing processes, cosmetic waxes focus on enhancing product performance and skin compatibility.

Industrial Wax: Uses and Industries Served

Industrial waxes are crucial in diverse sectors such as automotive, electronics, packaging, and construction, where they enhance product durability, lubrication, and insulation. These waxes, including paraffin, microcrystalline, and synthetic variants, improve manufacturing processes by providing moisture resistance, gloss, and adhesion properties. Their application ranges from coatings and molding to sealing and polishing, making them indispensable for industrial efficiency and product quality.

Regulatory Requirements for Cosmetic vs Industrial Wax

Cosmetic wax must comply with stringent regulatory requirements set by agencies such as the FDA or EU Cosmetics Regulation, ensuring purity, safety, and absence of harmful contaminants suitable for skin contact. Industrial wax standards prioritize performance characteristics like melting point and durability, with less emphasis on human safety and more on functional usage in manufacturing or lubrication. Compliance for cosmetic wax involves detailed safety assessments, ingredient transparency, and allergen testing, while industrial wax regulation focuses mainly on environmental and occupational safety standards.

Purity and Additive Profiles: A Comparative Analysis

Cosmetic wax features higher purity levels and minimal additives to ensure safe application on skin, often containing natural ingredients like beeswax or carnauba wax. Industrial wax, in contrast, includes various additives such as fillers, antioxidants, and fragrances tailored for durability and performance rather than skin compatibility. The purity and additive profiles directly impact the suitability of wax types for cosmetic formulations versus industrial uses like coatings and adhesives.

Environmental Impact: Cosmetic Wax vs Industrial Wax

Cosmetic wax is typically derived from natural sources such as beeswax or plant-based ingredients, making it biodegradable and less harmful to ecosystems compared to industrial wax, which often contains petroleum-based compounds with slow degradation rates. Industrial wax production and disposal contribute significantly to soil and water contamination due to persistent chemical residues, whereas cosmetic waxes break down more readily, reducing pollution levels. The use of sustainable, eco-friendly cosmetic waxes supports lower carbon footprints and aligns with environmentally conscious manufacturing and consumption practices.

Market Trends Influencing Cosmetic and Industrial Wax

The global cosmetic wax market is experiencing rapid growth driven by increasing demand for natural and organic personal care products, with beeswax and plant-based waxes dominating formulations. Industrial wax markets focus on applications such as packaging, automotive, and candles, where synthetic and paraffin waxes maintain high usage due to cost-efficiency and thermal properties. Emerging trends show a shift toward sustainable sourcing and bio-based alternatives in both sectors, responding to consumer preferences and regulatory pressures for eco-friendly materials.

Choosing the Right Wax for Your Application

Cosmetic waxes, such as beeswax and carnauba wax, are formulated for skin safety, providing smooth texture and moisturizing benefits crucial in skincare and makeup products. Industrial waxes, including paraffin and microcrystalline wax, offer high melting points, durability, and resistance to chemicals, making them ideal for manufacturing, packaging, and coating applications. Selecting the right wax depends on factors like intended use, safety requirements, melting temperature, and desired texture to ensure optimal performance.

Cosmetic wax vs Industrial wax Infographic

materialdif.com

materialdif.com