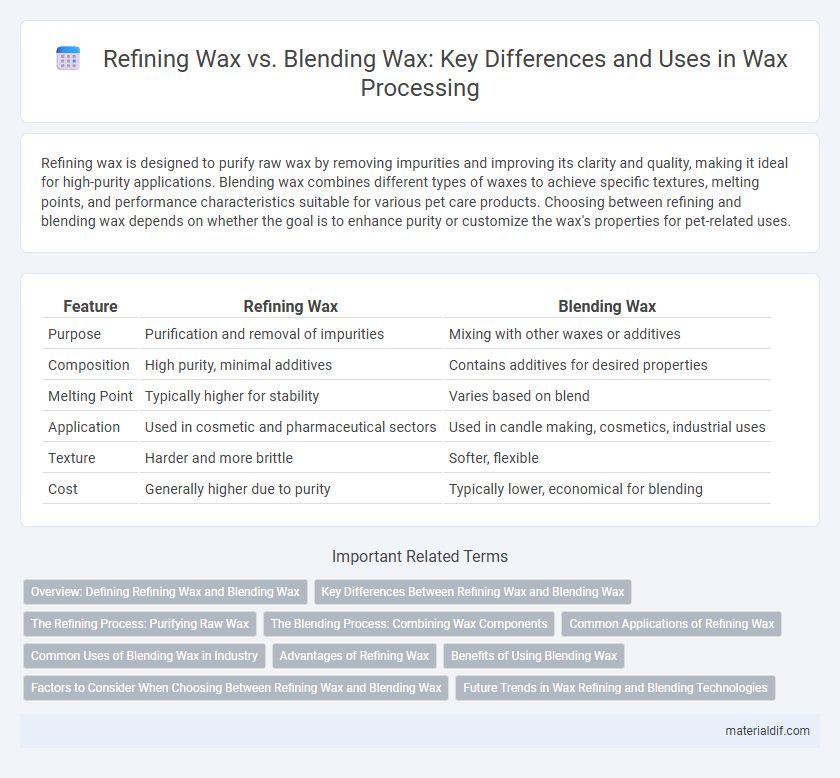

Refining wax is designed to purify raw wax by removing impurities and improving its clarity and quality, making it ideal for high-purity applications. Blending wax combines different types of waxes to achieve specific textures, melting points, and performance characteristics suitable for various pet care products. Choosing between refining and blending wax depends on whether the goal is to enhance purity or customize the wax's properties for pet-related uses.

Table of Comparison

| Feature | Refining Wax | Blending Wax |

|---|---|---|

| Purpose | Purification and removal of impurities | Mixing with other waxes or additives |

| Composition | High purity, minimal additives | Contains additives for desired properties |

| Melting Point | Typically higher for stability | Varies based on blend |

| Application | Used in cosmetic and pharmaceutical sectors | Used in candle making, cosmetics, industrial uses |

| Texture | Harder and more brittle | Softer, flexible |

| Cost | Generally higher due to purity | Typically lower, economical for blending |

Overview: Defining Refining Wax and Blending Wax

Refining wax involves purifying raw wax materials through processes like filtration and distillation to remove impurities, achieving a higher level of clarity and consistency. Blending wax refers to combining different types or grades of waxes to create a customized product with specific melting points, hardness, and performance characteristics. Both refining and blending are essential for producing quality waxes tailored for various industrial and cosmetic applications.

Key Differences Between Refining Wax and Blending Wax

Refining wax undergoes a purification process to remove impurities and enhance clarity, odor, and melting point, primarily used in applications requiring high purity such as cosmetics and pharmaceuticals. Blending wax, conversely, is created by mixing different types of waxes or additives to achieve specific texture, hardness, and performance characteristics for products like candles and polishes. The key differences lie in refining's focus on purification and consistency versus blending's emphasis on customization and functional properties.

The Refining Process: Purifying Raw Wax

The refining process involves purifying raw wax to remove impurities such as oils, dirt, and colorants, ensuring a cleaner and more consistent end product. Techniques like filtration, bleaching, and deodorizing enhance the wax's quality by improving its color, odor, and melting point. This purification is crucial for applications requiring high-purity wax, such as cosmetics and pharmaceuticals.

The Blending Process: Combining Wax Components

The blending process involves combining different wax components such as paraffin, beeswax, soy, and microcrystalline waxes to achieve specific melting points, hardness, and scent throw characteristics. This method allows manufacturers to tailor wax formulations for various candle types, optimizing burn time and fragrance release. Unlike refining, blending focuses on synergy between waxes rather than purifying a single wax source.

Common Applications of Refining Wax

Refining wax is primarily used to remove impurities from raw wax, resulting in a purified product ideal for cosmetics, pharmaceuticals, and food-grade applications. Its ability to enhance clarity and improve melting points makes it essential in candle making and polishes. Unlike blending wax, which combines different waxes for tailored properties, refining wax ensures consistent quality and performance in sensitive applications.

Common Uses of Blending Wax in Industry

Blending wax is predominantly used in the cosmetics industry for formulating creams, lip balms, and lotions due to its flexibility in adjusting texture and melting points. It also finds extensive application in candle making, providing smooth finishes and enhancing burn quality. Furthermore, blending wax is vital in industrial coatings and adhesives, where it improves spreadability and durability.

Advantages of Refining Wax

Refining wax offers superior purity and consistency by removing impurities and contaminants, resulting in a product ideal for high-quality applications such as cosmetics and pharmaceuticals. The enhanced melting point and color stability of refined wax improve performance in manufacturing processes and end-use durability. Compared to blending wax, refining wax guarantees better chemical stability and reduced odor, enhancing product safety and consumer appeal.

Benefits of Using Blending Wax

Blending wax offers superior flexibility by combining different wax types to achieve customized hardness, melting points, and textures tailored to specific applications such as cosmetics, candles, and industrial use. This ability to modify properties enhances performance, consistency, and cost-efficiency compared to single-type refining wax. Using blending wax improves product quality and allows manufacturers to meet diverse consumer needs with optimized formulations.

Factors to Consider When Choosing Between Refining Wax and Blending Wax

Refining wax offers superior purity and consistency, making it ideal for applications requiring high-quality, contaminant-free wax, while blending wax provides flexibility by combining properties from multiple wax types to achieve desired texture and melting points. Factors to consider include the end-use requirements such as hardness, melting temperature, scent retention, and compatibility with additives or pigments. Cost efficiency and production scale also play critical roles, as refining wax is typically more expensive and time-consuming, whereas blending wax allows for customization and faster processing.

Future Trends in Wax Refining and Blending Technologies

Future trends in wax refining emphasize advanced catalytic dewaxing and solvent extraction techniques to achieve higher purity and tailored molecular structures for specialized applications. Innovations in blending wax technologies focus on customizable formulations integrating bio-based and synthetic waxes to meet sustainability demands and enhance performance characteristics. Emerging digital process controls and AI-driven optimization are transforming both refining and blending operations, driving efficiency and product consistency in the wax industry.

Refining wax vs Blending wax Infographic

materialdif.com

materialdif.com