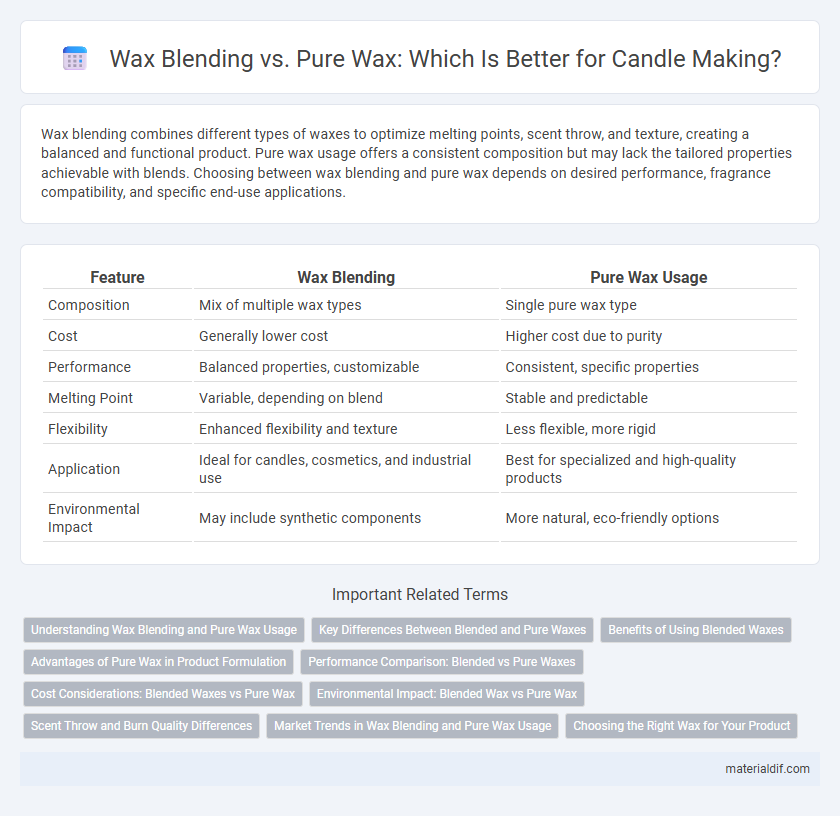

Wax blending combines different types of waxes to optimize melting points, scent throw, and texture, creating a balanced and functional product. Pure wax usage offers a consistent composition but may lack the tailored properties achievable with blends. Choosing between wax blending and pure wax depends on desired performance, fragrance compatibility, and specific end-use applications.

Table of Comparison

| Feature | Wax Blending | Pure Wax Usage |

|---|---|---|

| Composition | Mix of multiple wax types | Single pure wax type |

| Cost | Generally lower cost | Higher cost due to purity |

| Performance | Balanced properties, customizable | Consistent, specific properties |

| Melting Point | Variable, depending on blend | Stable and predictable |

| Flexibility | Enhanced flexibility and texture | Less flexible, more rigid |

| Application | Ideal for candles, cosmetics, and industrial use | Best for specialized and high-quality products |

| Environmental Impact | May include synthetic components | More natural, eco-friendly options |

Understanding Wax Blending and Pure Wax Usage

Wax blending involves combining different types of waxes to optimize melting points, texture, and fragrance throw, enhancing product performance in candles and cosmetics. Pure wax usage offers consistency and natural properties but may require precise handling due to limitations like brittleness or melting behavior. Understanding the benefits and trade-offs of wax blending versus pure wax helps manufacturers tailor products for durability, scent release, and user experience.

Key Differences Between Blended and Pure Waxes

Blended waxes combine natural and synthetic components, offering enhanced fragrance retention and improved melting points compared to pure waxes, which consist solely of natural materials like beeswax or soy wax. Pure waxes provide a cleaner burn and are often preferred for their ecological benefits and hypoallergenic properties. The choice between blended and pure waxes impacts scent throw, burn time, and environmental sustainability in candle-making and cosmetic formulations.

Benefits of Using Blended Waxes

Blended waxes combine natural and synthetic components to enhance texture, melting point, and scent throw compared to pure waxes. These blends offer improved burn time, stronger fragrance retention, and better compatibility with diverse fragrance oils and additives. Utilizing blended waxes in candle making results in a more consistent product with greater versatility and performance efficiency.

Advantages of Pure Wax in Product Formulation

Pure wax offers superior consistency and predictability in product formulation, ensuring uniform melting points and texture across batches. Its chemical stability minimizes the risk of unwanted reactions, enhancing product safety and longevity. Using pure wax allows formulators to tailor properties precisely, resulting in better performance and higher quality end products.

Performance Comparison: Blended vs Pure Waxes

Blended waxes often deliver enhanced performance by combining the durability and flexibility of multiple wax types, resulting in improved melting points and texture stability compared to pure waxes. Pure waxes, such as beeswax or soy wax, provide natural consistency and purity but may lack the optimal hardness or scent throw achieved through blending. Performance differences are critical in applications like candle making and cosmetics, where blend composition directly influences burn time, scent diffusion, and overall product quality.

Cost Considerations: Blended Waxes vs Pure Wax

Wax blending often reduces overall production costs by combining lower-priced waxes with premium ones, offering an economical balance without significantly compromising quality. Pure waxes, while delivering consistent properties and high purity, typically incur higher expenses due to the need for specialized sourcing and processing. Manufacturers must weigh cost factors against performance requirements when choosing between blended waxes and pure wax options.

Environmental Impact: Blended Wax vs Pure Wax

Blended wax often contains synthetic additives or petroleum-based components that can increase environmental pollution and hinder biodegradability compared to pure natural waxes like beeswax or soy wax. Pure wax typically offers a more sustainable and eco-friendly choice due to its renewable sourcing and complete biodegradability, reducing carbon footprint and landfill waste. Evaluating the environmental impact of wax products requires considering raw material sourcing, production emissions, and end-of-life decomposition behavior.

Scent Throw and Burn Quality Differences

Wax blending enhances scent throw by combining different waxes to optimize fragrance diffusion while maintaining a cleaner burn compared to some pure waxes. Pure waxes often provide a consistent, natural burn quality but may have a limited scent throw due to their singular composition. Selecting the right blend can achieve a balanced burn rate and potent fragrance release, improving overall candle performance.

Market Trends in Wax Blending and Pure Wax Usage

Wax blending is gaining significant traction in the market due to its enhanced performance characteristics and cost-efficiency, driving demand in automotive, cosmetic, and candle industries. Pure wax usage remains strong in niche applications where consistency and purity are critical, such as high-end cosmetics and specialty industrial products. Market data indicates a steady growth rate of 7% annually for wax blends, outperforming the 3% growth seen in pure wax segments, reflecting a shift towards multifunctional and customizable wax solutions.

Choosing the Right Wax for Your Product

Selecting the appropriate wax type impacts product performance, with wax blending offering enhanced melting points and tailored textures compared to pure wax usage. Blended waxes combine various natural and synthetic waxes to optimize hardness, scent throw, and burn time, meeting specific formulation needs. Pure waxes like soy or beeswax provide natural benefits but may lack the customization potential available through blends for specialized applications.

Wax Blending vs Pure Wax Usage Infographic

materialdif.com

materialdif.com