Synthetic wax offers consistent texture and melting points, making it ideal for industrial applications requiring precision and durability. Natural wax, derived from plant or animal sources, provides eco-friendly benefits and biodegradability but can vary in composition and performance. Choosing between synthetic and natural wax depends on the balance between sustainability and specific functional requirements.

Table of Comparison

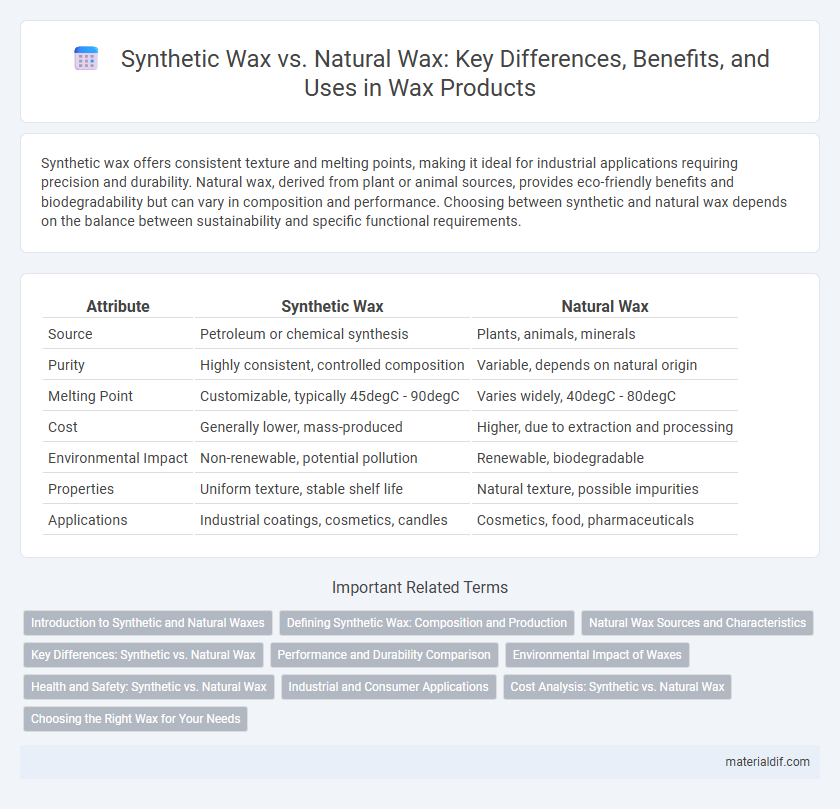

| Attribute | Synthetic Wax | Natural Wax |

|---|---|---|

| Source | Petroleum or chemical synthesis | Plants, animals, minerals |

| Purity | Highly consistent, controlled composition | Variable, depends on natural origin |

| Melting Point | Customizable, typically 45degC - 90degC | Varies widely, 40degC - 80degC |

| Cost | Generally lower, mass-produced | Higher, due to extraction and processing |

| Environmental Impact | Non-renewable, potential pollution | Renewable, biodegradable |

| Properties | Uniform texture, stable shelf life | Natural texture, possible impurities |

| Applications | Industrial coatings, cosmetics, candles | Cosmetics, food, pharmaceuticals |

Introduction to Synthetic and Natural Waxes

Synthetic waxes are man-made compounds derived from petroleum, characterized by consistent melting points and enhanced durability, making them ideal for industrial applications. Natural waxes, extracted from plants, animals, and minerals, offer biodegradable properties and complex chemical structures, commonly used in cosmetics, food coatings, and candle making. The choice between synthetic and natural wax depends on factors like environmental impact, performance requirements, and application specificity.

Defining Synthetic Wax: Composition and Production

Synthetic wax is a man-made substance primarily composed of long-chain hydrocarbons derived from petroleum, coal, or natural gas through processes like Fischer-Tropsch synthesis or polymerization. Unlike natural waxes that originate from plant, animal, or mineral sources, synthetic waxes are engineered to have consistent physical properties such as melting point, hardness, and crystallinity. These synthetic processes allow precise control over the wax's composition, resulting in tailored performance characteristics ideal for various industrial applications including coatings, candles, and cosmetics.

Natural Wax Sources and Characteristics

Natural waxes originate from plant, animal, and mineral sources, including beeswax, carnauba wax, candelilla wax, and montan wax, each possessing unique chemical compositions and physical properties. Beeswax, secreted by honeybees, exhibits high melting points and excellent emulsifying capabilities, while carnauba wax, derived from the leaves of the Brazilian palm Copernicia prunifera, is valued for its hardness and glossy finish. These natural waxes are biodegradable, sustainable, and commonly used in cosmetics, food packaging, and pharmaceuticals due to their non-toxic and hypoallergenic characteristics.

Key Differences: Synthetic vs. Natural Wax

Synthetic wax is chemically engineered, offering consistent purity, controlled melting points, and enhanced durability, making it ideal for industrial applications. Natural wax, derived from plant or animal sources such as beeswax or carnauba, contains complex hydrocarbons that provide unique aromas and biodegradability but may vary in composition. The key differences lie in origin, consistency, environmental impact, and specific performance attributes like melting behavior and hardness.

Performance and Durability Comparison

Synthetic wax exhibits superior performance and enhanced durability compared to natural wax due to its uniform molecular structure, providing consistent melting points and long-lasting protective properties. Natural wax, such as beeswax or carnauba, offers excellent biodegradability but may degrade faster under high temperatures or prolonged exposure to environmental stress. The synthetic variants maintain structural integrity and resist oxidation, making them ideal for applications requiring extended lifespan and reliable performance.

Environmental Impact of Waxes

Synthetic waxes, derived from petrochemical sources, often have a higher environmental footprint due to non-renewable resource extraction and slower biodegradability. Natural waxes, such as beeswax and carnauba, tend to be more eco-friendly, offering renewable sourcing and faster decomposition rates, which reduce soil and water pollution. However, sustainable harvesting practices are essential for minimizing environmental disruption and preserving biodiversity in natural wax production.

Health and Safety: Synthetic vs. Natural Wax

Synthetic waxes, often derived from petrochemicals, may release harmful volatile organic compounds (VOCs) during burning, posing respiratory risks and indoor air quality concerns. Natural waxes, such as beeswax or soy wax, offer safer alternatives with cleaner combustion and fewer toxic emissions, reducing health hazards. Opting for natural waxes enhances safety in home environments due to their non-toxic, biodegradable properties and lower environmental impact.

Industrial and Consumer Applications

Synthetic wax offers superior consistency, higher melting points, and enhanced chemical resistance compared to natural wax, making it ideal for industrial applications such as coatings, adhesives, and plastics manufacturing. Natural wax, derived from plant or animal sources, is prized in consumer products like cosmetics, food packaging, and candles for its biodegradability and natural origin. The choice between synthetic and natural wax heavily depends on performance requirements, environmental considerations, and cost-efficiency in both industrial and consumer markets.

Cost Analysis: Synthetic vs. Natural Wax

Synthetic wax generally offers a lower production cost due to its scalable petroleum-based manufacturing process, resulting in more affordable market prices compared to natural waxes. Natural waxes, derived from plants or animals such as beeswax or carnauba, involve higher extraction and purification expenses that increase their overall cost. Cost analysis must consider factors like raw material availability, processing complexity, and end-use application requirements to determine the most economical option for specific industries.

Choosing the Right Wax for Your Needs

Synthetic wax offers consistent melting points and superior durability, making it ideal for industrial applications and products requiring long-lasting performance. Natural wax, derived from beeswax or plant sources, excels in eco-friendliness and skin compatibility, preferred in cosmetics and organic products. Selecting the right wax depends on whether priority lies in environmental sustainability or enhanced physical properties for specialized uses.

Synthethic Wax vs Natural Wax Infographic

materialdif.com

materialdif.com