Container wax is specifically formulated to adhere to the sides of containers, ensuring a slower, more controlled burn without tunneling, making it ideal for jar candles. Pillar wax, on the other hand, is designed to be self-supporting and holds its shape, allowing it to be molded into freestanding pillars or shapes without a container. Both waxes feature distinct melting points and hardness levels tailored to their intended uses, optimizing burn performance and aesthetic appeal.

Table of Comparison

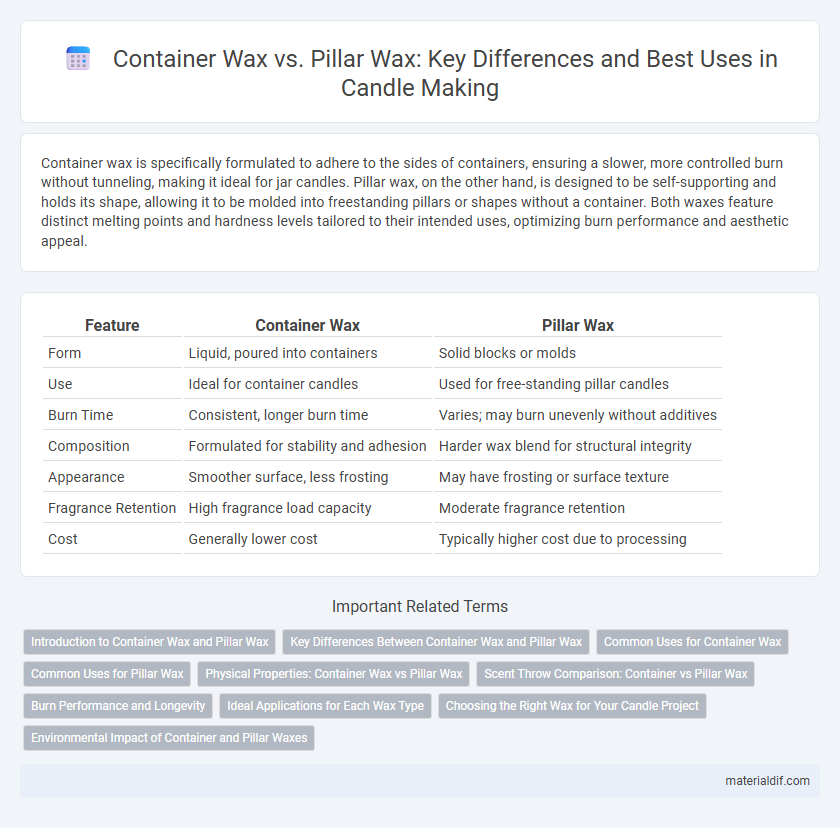

| Feature | Container Wax | Pillar Wax |

|---|---|---|

| Form | Liquid, poured into containers | Solid blocks or molds |

| Use | Ideal for container candles | Used for free-standing pillar candles |

| Burn Time | Consistent, longer burn time | Varies; may burn unevenly without additives |

| Composition | Formulated for stability and adhesion | Harder wax blend for structural integrity |

| Appearance | Smoother surface, less frosting | May have frosting or surface texture |

| Fragrance Retention | High fragrance load capacity | Moderate fragrance retention |

| Cost | Generally lower cost | Typically higher cost due to processing |

Introduction to Container Wax and Pillar Wax

Container wax is specifically formulated to adhere to the glass or metal containers used in candle making, exhibiting a lower melt point to ensure even burning and minimal shrinkage. Pillar wax, on the other hand, features a harder and denser composition designed to retain its shape without a container, often blending multiple types of wax for structural stability. Both wax types are optimized for their intended candle forms, with container wax prioritizing smooth finishes and scent throw, while pillar wax emphasizes durability and clean edges.

Key Differences Between Container Wax and Pillar Wax

Container wax is formulated to have a lower melt point and better adhesion, enabling it to harden moistly while securely bonding to glass or metal containers. Pillar wax features a higher melting temperature and greater stiffness, designed to hold its shape for freestanding candles without the need for a container. Key differences include melt point, hardness, scent throw, and container adherence, making container wax ideal for jar candles and pillar wax suited for decorative, self-supporting shapes.

Common Uses for Container Wax

Container wax is specifically formulated for use in glass, metal, or plastic containers to produce smooth, even candles without shrinking or cracking. Its unique chemical composition allows it to adhere well to container walls, providing a stable structure ideal for scented and decorative candles. Common uses for container wax include making jar candles, votives, and tealights, where retention of fragrance and a clean burn are essential.

Common Uses for Pillar Wax

Pillar wax is primarily used for molding decorative candles, offering a hard, dense texture that holds shape well during burning. This type of wax is favored in crafting free-standing candles due to its excellent scent retention and vibrant color compatibility. Common uses include creating artistic shapes and intricate designs where structural stability is essential.

Physical Properties: Container Wax vs Pillar Wax

Container wax exhibits a softer texture with a lower melting point typically ranging between 120degF to 130degF, ensuring it remains molten enough to adhere smoothly to glass containers during candle making. In contrast, pillar wax is harder and more brittle, with a higher melting point around 135degF to 145degF, allowing it to maintain a stable, self-supporting shape without a container. These physical properties influence the scent throw, burn rate, and structural integrity of the final candle product.

Scent Throw Comparison: Container vs Pillar Wax

Container wax typically offers a stronger scent throw due to its formulation designed for slower, controlled burning in enclosed vessels. Pillar wax, often denser and harder, provides a more subtle fragrance release as it burns less evenly and has a lower fragrance load capacity. The difference in scent diffusion between container and pillar wax significantly impacts the overall aromatic experience in candle usage.

Burn Performance and Longevity

Container wax is formulated with a higher soy or paraffin content, offering a smooth surface and slower, even burn ideal for glass or tins, enhancing longevity by maintaining structural integrity during combustion. Pillar wax, often a blend of paraffin and additives, provides a firmer texture suitable for freestanding candles but tends to burn faster with reduced melt pool formation, affecting overall burn time. Choosing the appropriate wax type directly impacts burn performance, with container wax delivering extended use and pillar wax prioritizing shape retention over longevity.

Ideal Applications for Each Wax Type

Container wax is ideal for making candles that require a smooth finish and strong scent throw, suitable for glass jars and tins due to its excellent adhesion and minimal shrinkage. Pillar wax is designed for free-standing candles like pillars and tapers, offering a harder texture and better structural support to maintain shape without the need for containers. Both waxes cater to specific candle-making needs, optimizing burn quality and aesthetic appeal based on their physical properties.

Choosing the Right Wax for Your Candle Project

Container wax offers excellent adhesion and a smooth texture ideal for glass jars, ensuring a stable burn and clear scent throw in candle making. Pillar wax, formulated with a harder texture, supports self-standing candles and maintains shape without a container, providing a longer burn time and less shrinkage. Selecting the appropriate wax depends on the candle style, with container wax favored for enclosed designs and pillar wax suited for freestanding decorative pieces.

Environmental Impact of Container and Pillar Waxes

Container wax typically has a lower environmental impact due to its efficient burn and minimal waste, as it melts within a confined space, reducing soot and emissions. Pillar wax often requires a higher volume of wax to maintain its shape, leading to increased raw material consumption and longer burn times, which can contribute to greater carbon emissions. Sustainable sourcing and the use of eco-friendly additives in both types can significantly mitigate their overall environmental footprint.

Container wax vs Pillar wax Infographic

materialdif.com

materialdif.com