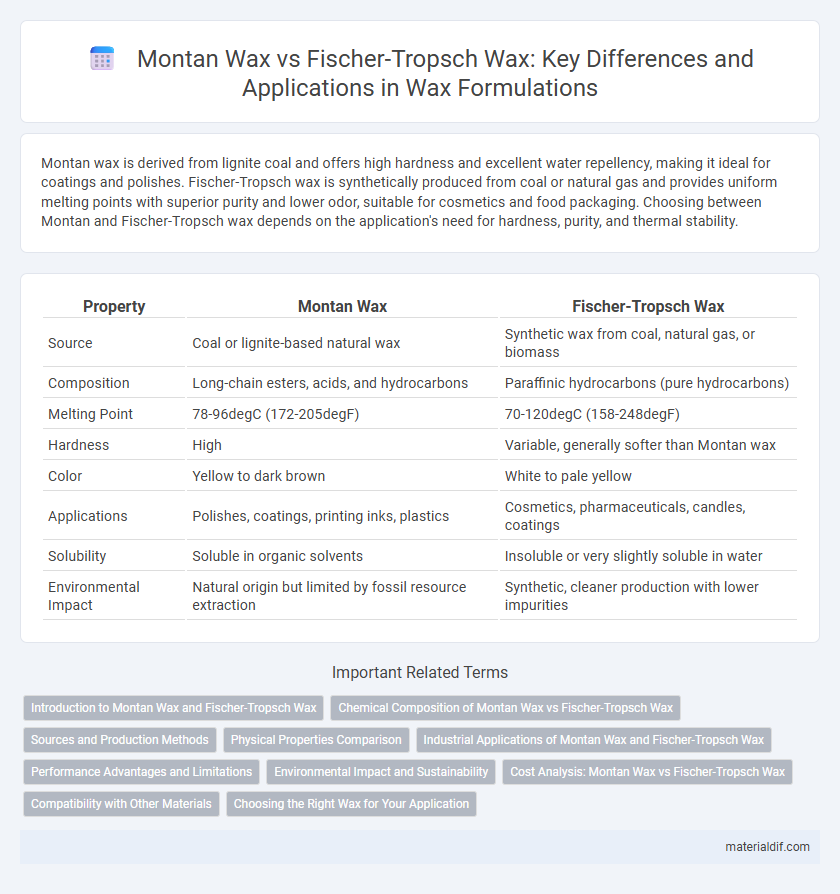

Montan wax is derived from lignite coal and offers high hardness and excellent water repellency, making it ideal for coatings and polishes. Fischer-Tropsch wax is synthetically produced from coal or natural gas and provides uniform melting points with superior purity and lower odor, suitable for cosmetics and food packaging. Choosing between Montan and Fischer-Tropsch wax depends on the application's need for hardness, purity, and thermal stability.

Table of Comparison

| Property | Montan Wax | Fischer-Tropsch Wax |

|---|---|---|

| Source | Coal or lignite-based natural wax | Synthetic wax from coal, natural gas, or biomass |

| Composition | Long-chain esters, acids, and hydrocarbons | Paraffinic hydrocarbons (pure hydrocarbons) |

| Melting Point | 78-96degC (172-205degF) | 70-120degC (158-248degF) |

| Hardness | High | Variable, generally softer than Montan wax |

| Color | Yellow to dark brown | White to pale yellow |

| Applications | Polishes, coatings, printing inks, plastics | Cosmetics, pharmaceuticals, candles, coatings |

| Solubility | Soluble in organic solvents | Insoluble or very slightly soluble in water |

| Environmental Impact | Natural origin but limited by fossil resource extraction | Synthetic, cleaner production with lower impurities |

Introduction to Montan Wax and Fischer-Tropsch Wax

Montan wax is a natural wax derived from lignite coal, known for its hard texture, high melting point, and excellent lubricating properties, making it valuable in coatings, polishes, and plastics. Fischer-Tropsch wax is a synthetic wax produced through the Fischer-Tropsch process by hydrogenating carbon monoxide, offering uniform molecular structure, high purity, and consistent performance in cosmetics, candles, and extrusion applications. Both waxes differ significantly in origin, chemical composition, and specific industrial uses, influencing their selection based on desired characteristics and environmental impact.

Chemical Composition of Montan Wax vs Fischer-Tropsch Wax

Montan wax is primarily composed of long-chain esters, acids, and alcohols derived from lignite coal, featuring a complex mixture of hydrocarbons with carbon chain lengths typically between C28 and C36. Fischer-Tropsch wax consists mainly of linear, saturated hydrocarbons produced through the catalytic hydrogenation of synthesis gas, with chain lengths ranging from C20 to C40, and lacks the ester and acid components present in Montan wax. The presence of functional groups such as esters and acids in Montan wax imparts distinct chemical reactivity and melting behavior compared to the pure hydrocarbon structure of Fischer-Tropsch wax.

Sources and Production Methods

Montan wax is derived from lignite coal and involves complex extraction and purification processes, primarily through solvent refining, to obtain a hard, high-melting-point wax rich in long-chain fatty acids and alcohols. Fischer-Tropsch wax is synthesized through the catalytic hydrogenation of carbon monoxide and hydrogen gases, producing a paraffinic wax with a highly uniform molecular structure and lower melting point compared to Montan wax. The distinct sources--fossil lignite for Montan wax versus syngas processed in Fischer-Tropsch synthesis--result in different chemical compositions and production techniques tailored for specific industrial applications.

Physical Properties Comparison

Montan wax exhibits a higher melting point, typically around 82-88degC, compared to Fischer-Tropsch wax, which melts between 75-90degC but often has a narrower range depending on synthesis conditions. Montan wax features greater hardness and brittleness due to its long-chain fatty acid esters, whereas Fischer-Tropsch waxes are characterized by a more uniform hydrocarbon structure resulting in better thermal stability and lower brittleness. Both waxes differ in density, with Montan wax generally having a density of 1.0-1.05 g/cm3, while Fischer-Tropsch wax ranges from 0.9-0.96 g/cm3, influencing their application in coatings, polishes, and industrial uses.

Industrial Applications of Montan Wax and Fischer-Tropsch Wax

Montan wax, derived from lignite coal, finds extensive industrial use in coatings, polishes, and rubber additives due to its high melting point and excellent hardness. Fischer-Tropsch wax, synthesized from carbon monoxide and hydrogen via catalytic processes, is favored in pharmaceuticals, cosmetics, and food packaging for its purity and controlled melting characteristics. Both waxes serve crucial roles in manufacturing lubrication, surface finishing, and chemical industries, but Montan wax excels in durability applications while Fischer-Tropsch wax offers superior chemical consistency.

Performance Advantages and Limitations

Montan wax offers superior hardness, high melting point, and excellent lubrication, making it ideal for applications requiring durability and resistance to wear, while Fischer-Tropsch wax delivers high purity and uniformity with low odor and color, beneficial for pharmaceuticals and cosmetics. Montan wax, derived from lignite coal, has limitations in brittleness and solubility compared to the synthetic Fischer-Tropsch wax, which boasts better chemical stability and lower melting range for improved blending flexibility. Performance advantages of Fischer-Tropsch wax include consistent quality and compatibility with polymers, whereas Montan wax excels in mechanical strength and natural origin benefits.

Environmental Impact and Sustainability

Montan wax, derived from lignite coal, undergoes extensive refining processes resulting in higher energy consumption and significant greenhouse gas emissions compared to Fischer-Tropsch wax, which is synthetically produced from biomass or natural gas through catalytic conversion. Fischer-Tropsch wax offers improved sustainability due to its lower carbon footprint and potential for renewable feedstock integration, aligning better with circular economy principles. Montan wax production also raises concerns over mining impacts, while Fischer-Tropsch wax benefits from scalable, cleaner technological advancements that reduce environmental degradation.

Cost Analysis: Montan Wax vs Fischer-Tropsch Wax

Montan wax is generally more expensive than Fischer-Tropsch wax due to its extraction from lignite coal and extensive refining process, which increases production costs. Fischer-Tropsch wax, synthesized from natural gas via the Fischer-Tropsch process, offers a cost advantage with consistent quality and lower raw material expenses. Cost analysis reveals that while Montan wax commands higher prices for specialty applications requiring hardness and polish, Fischer-Tropsch wax is preferred in mass production for its economic efficiency and customizable properties.

Compatibility with Other Materials

Montan wax offers superior compatibility with natural and synthetic resins, making it ideal for coatings and polishes requiring flexibility and adhesion. Fischer-Tropsch wax, characterized by its high purity and consistent molecular structure, blends well with polymers such as polyethylene and polypropylene, enhancing surface smoothness and thermal stability. Both waxes exhibit excellent compatibility with additives, but Montan wax is preferred when formulation demands enhanced plasticization and gloss.

Choosing the Right Wax for Your Application

Montan wax offers superior hardness and high melting points, making it ideal for applications in polishes, coatings, and rubber compounding where durability and heat resistance are essential. Fischer-Tropsch wax, characterized by its purity, uniform molecular structure, and excellent chemical stability, suits cosmetic formulations, adhesives, and food packaging requiring non-toxicity and consistent performance. Selecting the right wax depends on application-specific requirements such as hardness, melting point, chemical resistance, and regulatory compliance to ensure optimal functionality and product quality.

Montan Wax vs Fischer-Tropsch Wax Infographic

materialdif.com

materialdif.com