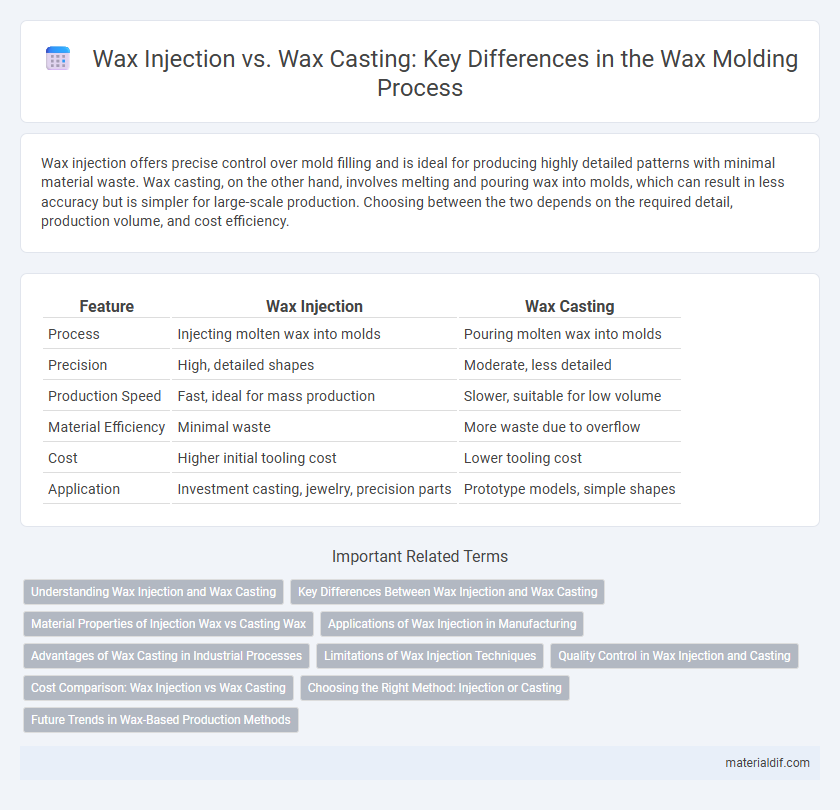

Wax injection offers precise control over mold filling and is ideal for producing highly detailed patterns with minimal material waste. Wax casting, on the other hand, involves melting and pouring wax into molds, which can result in less accuracy but is simpler for large-scale production. Choosing between the two depends on the required detail, production volume, and cost efficiency.

Table of Comparison

| Feature | Wax Injection | Wax Casting |

|---|---|---|

| Process | Injecting molten wax into molds | Pouring molten wax into molds |

| Precision | High, detailed shapes | Moderate, less detailed |

| Production Speed | Fast, ideal for mass production | Slower, suitable for low volume |

| Material Efficiency | Minimal waste | More waste due to overflow |

| Cost | Higher initial tooling cost | Lower tooling cost |

| Application | Investment casting, jewelry, precision parts | Prototype models, simple shapes |

Understanding Wax Injection and Wax Casting

Wax injection involves injecting molten wax into precise molds to form detailed patterns used in investment casting, ensuring high dimensional accuracy and smooth surface finishes. Wax casting refers to the broader process of creating wax models, which can include hand sculpting, pouring, or injection methods, serving as essential patterns for producing metal parts through lost-wax casting. Understanding the differences highlights wax injection's efficiency for complex, repeatable designs versus wax casting's versatility for custom or intricate shapes.

Key Differences Between Wax Injection and Wax Casting

Wax injection involves injecting molten wax into a mold under pressure, ensuring precise and consistent replication of intricate details, while wax casting uses pouring or dipping techniques to form wax patterns. Injection offers higher accuracy and repeatability, ideal for complex jewelry or industrial components, whereas casting is more suitable for larger, less detailed parts due to its simpler process. The primary distinction lies in the method of wax pattern creation--pressure-driven filling in injection versus gravity or manual layering in casting--impacting precision and production efficiency.

Material Properties of Injection Wax vs Casting Wax

Injection wax exhibits high flowability and fine detail reproduction due to its low viscosity and uniform particle size, making it ideal for precise mold filling. Casting wax features higher brittleness and lower tensile strength, suited for easy burnout and clean removal during investment casting. The thermal expansion of injection wax is minimal, ensuring dimensional stability, while casting wax tends to have greater expansion, which can affect final casting accuracy.

Applications of Wax Injection in Manufacturing

Wax injection plays a crucial role in manufacturing by producing highly precise and intricate patterns used in investment casting, especially for aerospace, automotive, and jewelry industries. This technique allows for consistent and repeatable wax prototypes, enabling superior surface finishes and dimensional accuracy essential for complex metal parts. The process supports high-volume production while reducing material waste and improving overall molding efficiency compared to traditional wax casting methods.

Advantages of Wax Casting in Industrial Processes

Wax casting offers superior precision and intricate detail reproduction compared to wax injection, making it ideal for complex industrial components. This process enables the creation of consistent and high-quality molds with minimal material waste, enhancing overall manufacturing efficiency. Its ability to produce intricate geometries supports advanced applications in aerospace, automotive, and jewelry industries.

Limitations of Wax Injection Techniques

Wax injection techniques face limitations such as inconsistencies in filling fine details, leading to defects in the final pattern. Temperature control is critical, with improper heating causing wax degradation or incomplete mold filling. The method is also restricted by the size and complexity of patterns, making it less suitable for large or highly intricate components compared to wax casting.

Quality Control in Wax Injection and Casting

Wax injection ensures consistent mold filling under controlled pressure and temperature, minimizing defects such as voids and shrinkage with precise dimensional accuracy. Wax casting involves pouring molten wax into molds, susceptible to air bubbles and surface irregularities, demanding rigorous inspection protocols for uniformity. Quality control in wax injection emphasizes repeatability and defect detection through automated sensors, while wax casting relies heavily on manual inspection and post-processing corrections to maintain product standards.

Cost Comparison: Wax Injection vs Wax Casting

Wax injection offers a higher initial investment due to the cost of specialized molds and machinery, but lower per-unit expenses make it more cost-effective for large production runs. Wax casting involves simpler tools and lower upfront costs, making it suitable for small batches or prototypes despite higher material waste and labor intensity. Evaluating production volume and complexity is crucial to determining the most economical wax pattern manufacturing method.

Choosing the Right Method: Injection or Casting

Wax injection offers precise control and consistency, ideal for producing complex, detailed components with minimal material waste in high-volume applications. Wax casting is preferred for creating larger, less intricate shapes where flexibility in design adjustments and cost-effective prototyping are important. Selecting between wax injection and casting depends on factors such as part complexity, production volume, and cost efficiency requirements.

Future Trends in Wax-Based Production Methods

Wax injection and wax casting are evolving with advancements in additive manufacturing and automation technologies, enabling greater precision and faster production cycles. Future trends highlight the integration of AI-driven process control to optimize wax pattern uniformity and reduce material waste in investment casting applications. Sustainable wax formulations and hybrid manufacturing techniques are expected to enhance efficiency and environmental compatibility in wax-based production methods.

Wax injection vs Wax casting Infographic

materialdif.com

materialdif.com