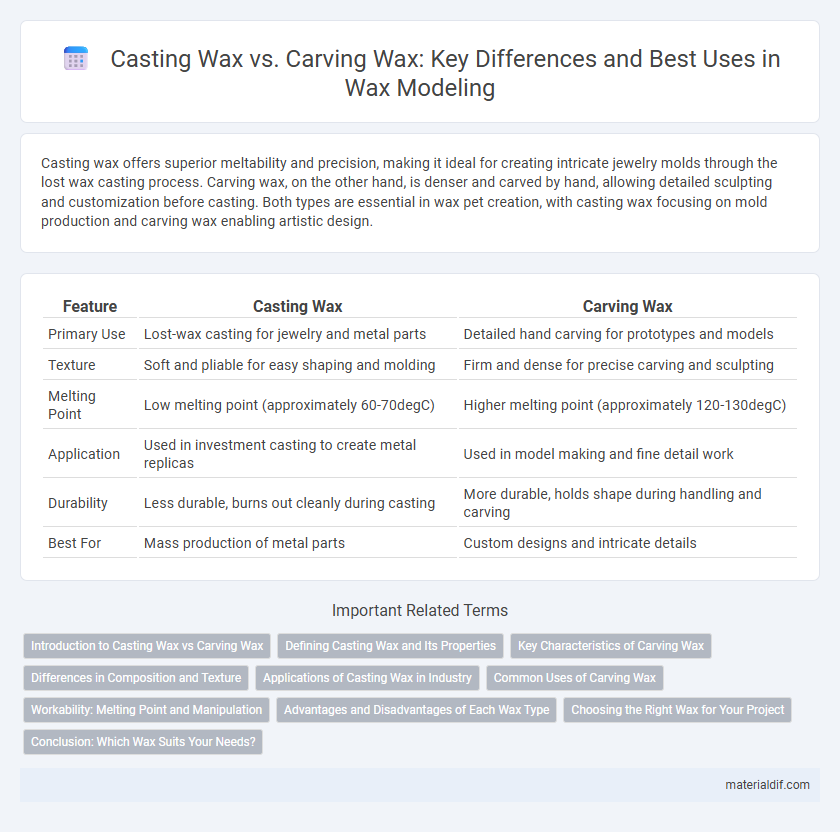

Casting wax offers superior meltability and precision, making it ideal for creating intricate jewelry molds through the lost wax casting process. Carving wax, on the other hand, is denser and carved by hand, allowing detailed sculpting and customization before casting. Both types are essential in wax pet creation, with casting wax focusing on mold production and carving wax enabling artistic design.

Table of Comparison

| Feature | Casting Wax | Carving Wax |

|---|---|---|

| Primary Use | Lost-wax casting for jewelry and metal parts | Detailed hand carving for prototypes and models |

| Texture | Soft and pliable for easy shaping and molding | Firm and dense for precise carving and sculpting |

| Melting Point | Low melting point (approximately 60-70degC) | Higher melting point (approximately 120-130degC) |

| Application | Used in investment casting to create metal replicas | Used in model making and fine detail work |

| Durability | Less durable, burns out cleanly during casting | More durable, holds shape during handling and carving |

| Best For | Mass production of metal parts | Custom designs and intricate details |

Introduction to Casting Wax vs Carving Wax

Casting wax and carving wax serve distinct purposes in the jewelry making process, with casting wax primarily designed for investment casting due to its ability to burn out cleanly without residue. Carving wax is softer and more pliable, allowing jewelers to sculpt intricate designs and fine details directly by hand. Understanding the differences in hardness, burnout properties, and workability is essential for selecting the appropriate wax for precise model creation and successful final casting.

Defining Casting Wax and Its Properties

Casting wax is a specialized material used primarily in the lost-wax casting process for creating precise metal parts and jewelry. It melts cleanly without residue, allowing for detailed mold creation and accurate replication of intricate designs. Its fine texture and consistent composition make casting wax ideal for producing smooth, high-quality casts in various metals.

Key Characteristics of Carving Wax

Carving wax is a firm, dense material designed for precise sculpting and shaping, offering excellent detail retention for intricate designs. It is typically used in lost-wax casting for jewelry and dental applications due to its ability to hold sharp edges and fine textures. Unlike casting wax, which melts easily for mold creation, carving wax maintains its shape under heat, enabling artists to refine complex patterns before casting.

Differences in Composition and Texture

Casting wax typically consists of a blend of paraffin, microcrystalline waxes, and resins designed to melt uniformly for precise mold filling, offering a smooth, slightly soft texture ideal for intricate detail reproduction. Carving wax, on the other hand, is formulated with a harder composition, often incorporating beeswax or synthetic polymers, providing a firm yet workable texture that allows artists to sculpt and refine shapes directly. The key differences lie in casting wax's low melting point and consistency for meltability versus carving wax's rigidity and tactile resistance for manual manipulation.

Applications of Casting Wax in Industry

Casting wax is extensively used in the jewelry and dental industries due to its excellent moldability and ability to produce precise, intricate designs through investment casting. Its low melting point and clean burn characteristics make it ideal for creating detailed metal parts and replicas in aerospace and automotive manufacturing. Casting wax ensures high-quality prototypes and final components, enhancing production accuracy and reducing post-processing time.

Common Uses of Carving Wax

Carving wax is primarily used in detailed jewelry making and dental applications where precision and intricate designs are essential. Unlike casting wax, carving wax offers a firmer texture that allows artists and technicians to sculpt fine details, making it ideal for custom jewelry prototypes and dental prosthetics. Its ability to hold sharp edges and complex shapes makes it a preferred choice for craftsmen requiring accuracy in their work.

Workability: Melting Point and Manipulation

Casting wax offers a lower melting point, making it ideal for precise molding and smooth surface finishes during the lost-wax casting process. Carving wax has a higher melting point, providing firm resistance for detailed sculpting and easier manipulation with hand tools. This distinction in workability and thermal properties directly influences the choice of wax for jewelry design and model fabrication.

Advantages and Disadvantages of Each Wax Type

Casting wax offers precise moldability and smooth surface finish, making it ideal for detailed jewelry designs, but it is brittle and can break easily during handling. Carving wax provides greater durability and allows for intricate hand-carved details, though it may require more effort to achieve a polished surface and can be less accurate in fine patterns. Selecting between casting and carving wax depends on the project's complexity, desired texture, and handling preferences.

Choosing the Right Wax for Your Project

Casting wax offers exceptional fluidity and is ideal for detailed molds in jewelry and metal casting, whereas carving wax provides a firmer texture suited for manual sculpting and intricate designs. Selecting the right wax depends on project requirements: use casting wax for precision casting and fine reproduction, while carving wax is preferable for direct craftsmanship and detailed carving work. Understanding the properties of each wax type ensures optimal results in modeling accuracy and finish quality.

Conclusion: Which Wax Suits Your Needs?

Choosing between casting wax and carving wax depends on the project's precision and application requirements. Casting wax offers superior detail and smoothness, ideal for creating intricate jewelry pieces, while carving wax provides greater durability and ease of shaping for larger models and prototypes. Assessing the complexity and final use of your design ensures the optimal wax type enhances both workflow and end results.

Casting Wax vs Carving Wax Infographic

materialdif.com

materialdif.com