Mold release wax is specifically formulated to prevent materials from sticking to molds during manufacturing, providing a smooth separation surface without affecting the mold's finish. Polishing wax enhances the appearance of surfaces by filling in minor scratches and imparting a glossy shine, while protecting the underlying material from contaminants. Choosing the right wax depends on whether the priority is ease of mold release or surface finishing and protection.

Table of Comparison

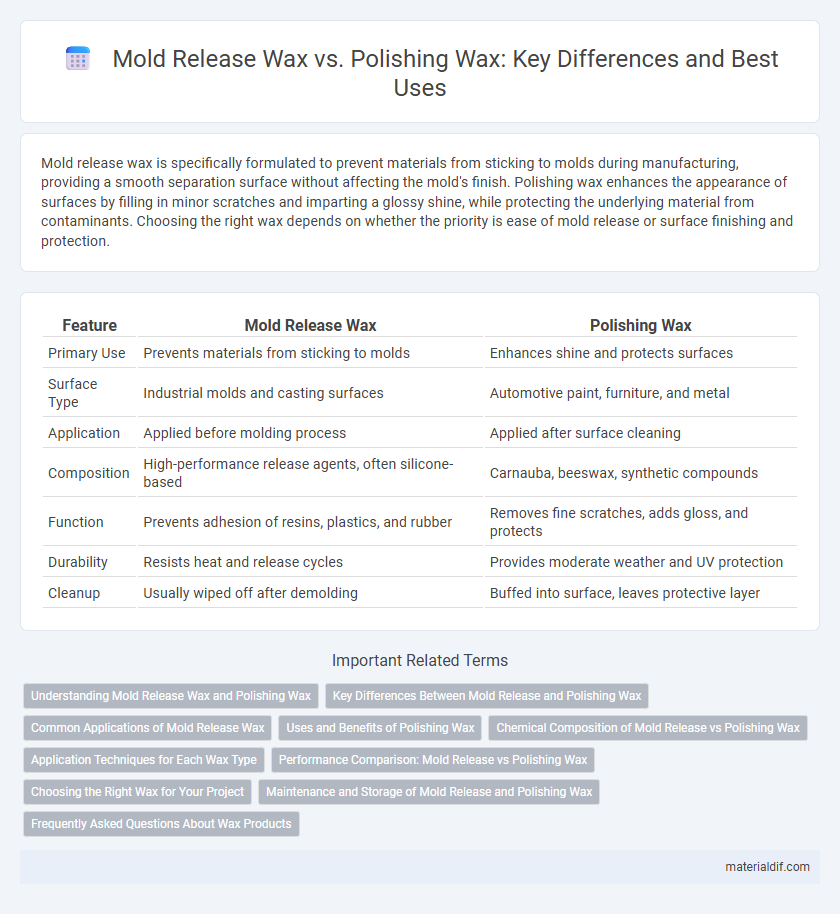

| Feature | Mold Release Wax | Polishing Wax |

|---|---|---|

| Primary Use | Prevents materials from sticking to molds | Enhances shine and protects surfaces |

| Surface Type | Industrial molds and casting surfaces | Automotive paint, furniture, and metal |

| Application | Applied before molding process | Applied after surface cleaning |

| Composition | High-performance release agents, often silicone-based | Carnauba, beeswax, synthetic compounds |

| Function | Prevents adhesion of resins, plastics, and rubber | Removes fine scratches, adds gloss, and protects |

| Durability | Resists heat and release cycles | Provides moderate weather and UV protection |

| Cleanup | Usually wiped off after demolding | Buffed into surface, leaves protective layer |

Understanding Mold Release Wax and Polishing Wax

Mold release wax is designed to create a barrier that prevents molded materials from sticking to surfaces, making it essential for efficient demolding in manufacturing processes. Polishing wax, on the other hand, is formulated to enhance the shine and protect surfaces by filling minor imperfections and providing a smooth, glossy finish. Understanding the distinct chemical compositions and applications of mold release wax and polishing wax ensures optimal results in both industrial molding and surface finishing.

Key Differences Between Mold Release and Polishing Wax

Mold release wax is specifically formulated to create a barrier that prevents adhesion of materials such as resin or concrete to molds, ensuring easy separation without damaging surfaces. Polishing wax, on the other hand, is designed to enhance surface shine and protect finishes by filling in minor scratches and providing a durable, glossy layer on materials like automotive paint or wood. The key difference lies in their primary functions: mold release wax prioritizes non-stick properties for manufacturing processes, while polishing wax focuses on aesthetic improvement and surface protection.

Common Applications of Mold Release Wax

Mold release wax is primarily used in industrial applications to ensure smooth separation between molds and cast materials, preventing adhesion and surface damage. Common applications include fiberglass molding, concrete casting, and plastic forming where consistent demolding is critical. Unlike polishing wax, which enhances surface shine and protection, mold release wax focuses on creating a thin barrier to facilitate easy removal of parts.

Uses and Benefits of Polishing Wax

Polishing wax enhances the shine and surface protection of materials such as automotive paint, wood, and metal by creating a smooth, reflective finish while sealing out moisture and contaminants. Unlike mold release wax, which is primarily used to prevent adhesion of casting materials in molds, polishing wax improves durability and water resistance, extending the lifespan of surfaces. Its benefits include easy application, restoration of color depth, and reduction of minor scratches and swirl marks for a long-lasting, glossy appearance.

Chemical Composition of Mold Release vs Polishing Wax

Mold release wax typically contains silicones, paraffin, or carnauba wax combined with additives designed to create a thin, non-stick barrier that facilitates easy separation of molded parts without compromising detail. Polishing wax often consists of natural waxes like carnauba and beeswax, blended with solvents and fine abrasives to enhance surface shine and provide a protective layer. The chemical composition of mold release wax prioritizes lubricity and quick vaporization, whereas polishing wax emphasizes hardness and gloss retention through durable resin blends.

Application Techniques for Each Wax Type

Mold release wax is primarily applied in thin, even layers using a soft cloth or spray to ensure smooth separation between the mold and cast, preventing damage and defects. Polishing wax requires buffing with a clean microfiber pad or polishing machine to enhance surface shine and protection, employing circular motions for uniform coverage. Proper application of mold release wax optimizes demolding efficiency, while precise polishing wax techniques maximize gloss and durability on finished surfaces.

Performance Comparison: Mold Release vs Polishing Wax

Mold release wax is engineered to create a non-stick barrier between molds and cast materials, optimizing ease of separation and minimizing surface defects, while polishing wax is formulated to enhance surface shine and provide protective coatings on finished products. Performance comparison reveals mold release wax excels in preventing adhesion and reducing cycle times during manufacturing, whereas polishing wax delivers improved aesthetic qualities and durability against environmental factors. Selecting the appropriate wax depends on application requirements, balancing release efficiency and surface finish performance for optimal results.

Choosing the Right Wax for Your Project

Mold release wax is specifically formulated to prevent materials from adhering to molds, ensuring smooth demolding in resin, fiberglass, and composite projects. Polishing wax is designed to enhance surface shine and protect finishes on automotive paint, metal, and wood. Selecting the right wax depends on whether the goal is to facilitate part release during fabrication or to improve and protect surface appearance after completion.

Maintenance and Storage of Mold Release and Polishing Wax

Mold release wax requires cool, dry storage to maintain its non-stick properties and prevent contamination, ensuring consistent application during mold maintenance. Polishing wax, on the other hand, benefits from airtight containers to preserve its abrasive qualities and prevent hardening or drying out, optimizing surface finish longevity. Proper maintenance includes regular cleaning of application tools and avoiding exposure to direct sunlight or extreme temperatures for both wax types.

Frequently Asked Questions About Wax Products

Mold release wax is formulated to prevent materials from sticking to molds during manufacturing, offering high heat resistance and easy removal, while polishing wax is designed to enhance surface shine and provide protective coatings on finished products. FAQs often address differences in application, durability, and chemical composition between these wax types, as mold release wax prioritizes slip properties and heat stability, whereas polishing wax emphasizes surface gloss and scratch resistance. Choosing the appropriate wax depends on the specific industrial or cosmetic requirement, including factors like temperature tolerance, ease of cleanup, and desired finish quality.

Mold release wax vs Polishing wax Infographic

materialdif.com

materialdif.com