Low-melt wax melts at lower temperatures, making it ideal for delicate applications such as candle making and cosmetics where gentle heating is essential. High-melt wax requires higher temperatures to melt, providing increased durability and heat resistance, which is suitable for industrial uses and molding processes. Choosing between low-melt and high-melt wax depends on the specific melting point requirements and performance characteristics needed for the intended application.

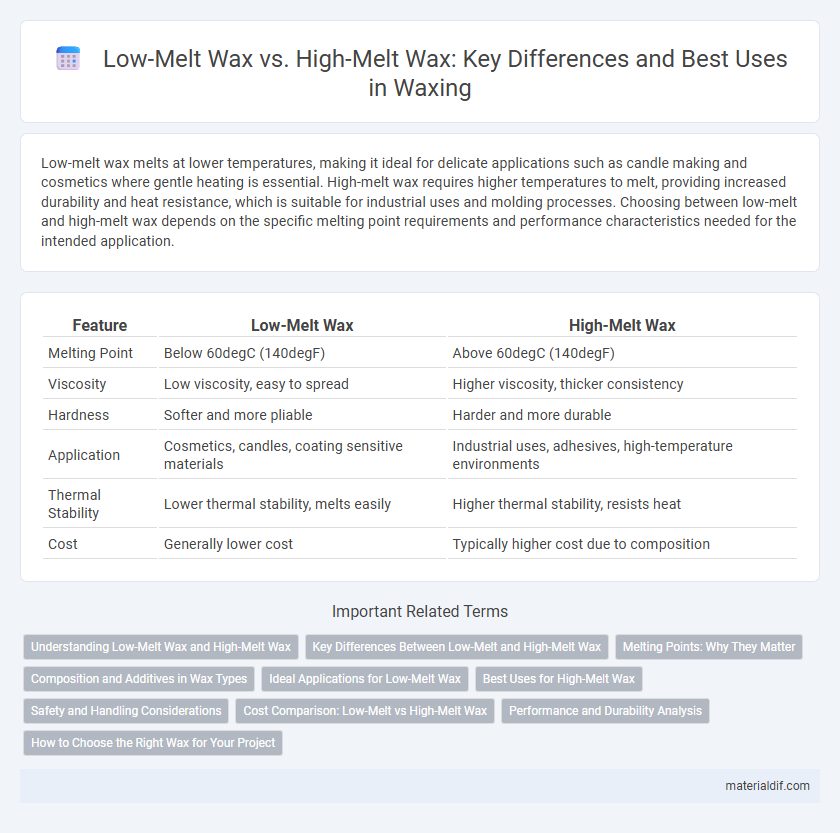

Table of Comparison

| Feature | Low-Melt Wax | High-Melt Wax |

|---|---|---|

| Melting Point | Below 60degC (140degF) | Above 60degC (140degF) |

| Viscosity | Low viscosity, easy to spread | Higher viscosity, thicker consistency |

| Hardness | Softer and more pliable | Harder and more durable |

| Application | Cosmetics, candles, coating sensitive materials | Industrial uses, adhesives, high-temperature environments |

| Thermal Stability | Lower thermal stability, melts easily | Higher thermal stability, resists heat |

| Cost | Generally lower cost | Typically higher cost due to composition |

Understanding Low-Melt Wax and High-Melt Wax

Low-melt wax typically has a melting point below 90degC, making it ideal for applications requiring quick melting and easy spreading, such as cosmetics and cold casting. High-melt waxes melt above 90degC, offering greater thermal stability and durability, suitable for industrial molding and high-temperature sealing. Understanding the melting points and performance characteristics of low-melt versus high-melt waxes is crucial for selecting the right wax based on specific manufacturing or crafting needs.

Key Differences Between Low-Melt and High-Melt Wax

Low-melt waxes soften between 45degC and 65degC, offering smooth application and subtle finish, ideal for cosmetics and encaustic art. High-melt waxes melt above 65degC, providing greater structural strength and durability, suitable for industrial uses and candle making. The primary differences lie in their melting points, hardness, and application-specific properties.

Melting Points: Why They Matter

Low-melt wax typically melts between 40degC and 60degC, making it ideal for applications requiring quick melting and easy handling, such as candle making and cosmetics. High-melt wax melts above 65degC, offering greater heat resistance and durability crucial for industrial uses, automotive products, and heavy-duty coatings. Understanding these melting points is essential for selecting the right wax to optimize performance, safety, and application efficiency.

Composition and Additives in Wax Types

Low-melt wax typically contains softer hydrocarbons and higher proportions of plasticizers or oils, enhancing its pliability and flow at lower temperatures, making it ideal for delicate casting or coating applications. High-melt wax consists mainly of longer-chain paraffinic or microcrystalline components with fewer additives, resulting in increased hardness and thermal stability suited for high-temperature molding or industrial uses. Additives like stabilizers, tackifiers, and fragrances are selectively integrated depending on the wax's intended performance, directly influencing its melting range and mechanical properties.

Ideal Applications for Low-Melt Wax

Low-melt wax is ideal for applications requiring a gentle heat threshold to prevent damage to sensitive materials such as electronics, cosmetics, and pharmaceuticals. Its melting point typically ranges between 40degC to 60degC, making it perfect for embedding, sealing, and coating processes where controlled softening and easy removal are crucial. Industries utilizing thermal transfer ribbons, candle-making, and packaging often prefer low-melt wax for its smooth application and reduced energy consumption.

Best Uses for High-Melt Wax

High-melt wax offers excellent thermal stability and durability, making it ideal for applications requiring strong structural integrity, such as industrial casting and high-temperature molding processes. Its higher melting point ensures it maintains shape under heat stress, suitable for automotive and electrical component manufacturing. High-melt wax is also preferred for producing precision models in investment casting due to its resistance to deformation during handling and processing.

Safety and Handling Considerations

Low-melt wax typically melts below 120degF, reducing burn risk and making it safer for direct skin contact in applications like candles and cosmetics. High-melt wax solidifies at temperatures above 120degF, requiring careful handling to prevent burns and ensuring proper ventilation to avoid inhaling fumes during heating. Using appropriate protective gear and temperature controls is essential for safely managing both low-melt and high-melt wax types in industrial and craft settings.

Cost Comparison: Low-Melt vs High-Melt Wax

Low-melt wax typically costs more due to specialized raw materials and precise formulation required for maintaining a lower melting point. High-melt waxes are generally less expensive as they use more common hydrocarbons, resulting in lower production expenses. When selecting between low-melt and high-melt wax, manufacturers consider these cost differences alongside application requirements to optimize budget efficiency.

Performance and Durability Analysis

Low-melt wax offers faster melting and better mold filling, improving efficiency in applications requiring quick setting times and detailed impressions, but it tends to be less durable under high-temperature conditions. High-melt wax provides superior performance in heat resistance and structural integrity, making it ideal for applications demanding prolonged exposure to heat and mechanical stress. Durability analysis shows that high-melt wax maintains stability and shape retention longer, while low-melt wax excels in precision but may deform under intense thermal stress.

How to Choose the Right Wax for Your Project

Selecting the right wax for your project depends on the melting point requirements and the intended application. Low-melt wax softens below 130degF, making it ideal for delicate molds, coatings, and easy release formulations, while high-melt wax, solidifying above 150degF, suits applications requiring durability, heat resistance, and structural integrity. Consider factors such as flexibility, adhesion, and exposure conditions to ensure optimal performance with either low-melt or high-melt wax types.

Low-Melt Wax vs High-Melt Wax Infographic

materialdif.com

materialdif.com