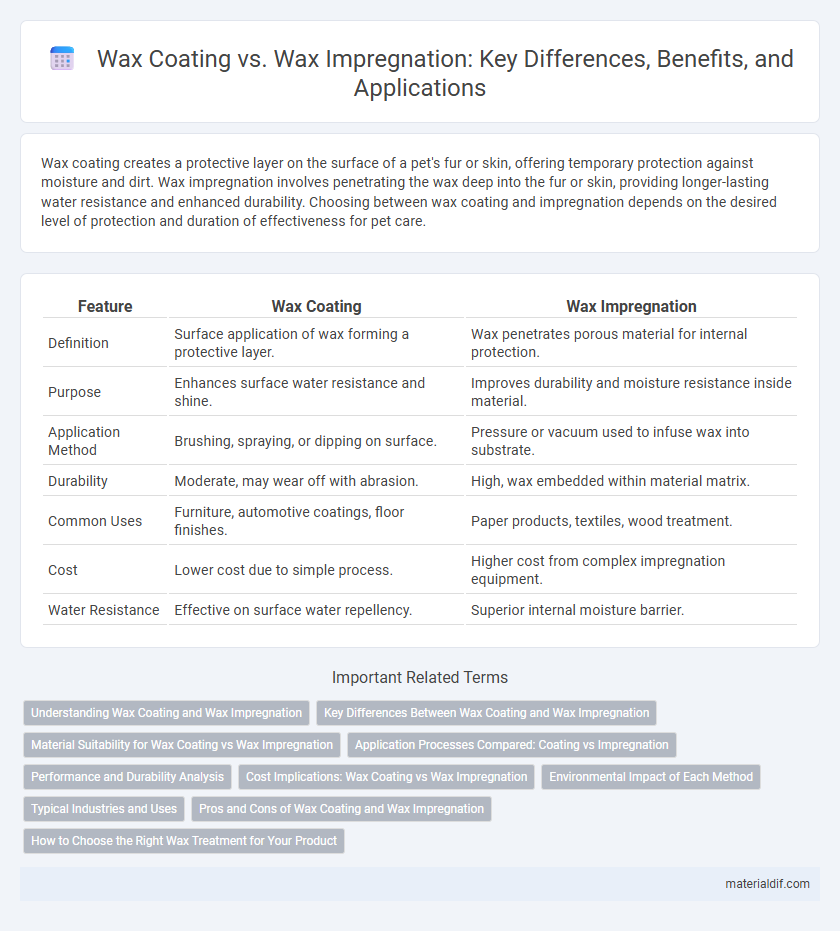

Wax coating creates a protective layer on the surface of a pet's fur or skin, offering temporary protection against moisture and dirt. Wax impregnation involves penetrating the wax deep into the fur or skin, providing longer-lasting water resistance and enhanced durability. Choosing between wax coating and impregnation depends on the desired level of protection and duration of effectiveness for pet care.

Table of Comparison

| Feature | Wax Coating | Wax Impregnation |

|---|---|---|

| Definition | Surface application of wax forming a protective layer. | Wax penetrates porous material for internal protection. |

| Purpose | Enhances surface water resistance and shine. | Improves durability and moisture resistance inside material. |

| Application Method | Brushing, spraying, or dipping on surface. | Pressure or vacuum used to infuse wax into substrate. |

| Durability | Moderate, may wear off with abrasion. | High, wax embedded within material matrix. |

| Common Uses | Furniture, automotive coatings, floor finishes. | Paper products, textiles, wood treatment. |

| Cost | Lower cost due to simple process. | Higher cost from complex impregnation equipment. |

| Water Resistance | Effective on surface water repellency. | Superior internal moisture barrier. |

Understanding Wax Coating and Wax Impregnation

Wax coating involves applying a thin layer of wax on a surface to create a protective barrier against moisture, dirt, and wear, commonly used on wood, leather, and automotive finishes. Wax impregnation, by contrast, penetrates the material's pores, enhancing internal protection and durability, often utilized in textiles and paper products. Understanding the differences in application and performance helps in selecting the appropriate wax treatment for specific materials and environmental conditions.

Key Differences Between Wax Coating and Wax Impregnation

Wax coating involves applying a thin, protective layer of wax on the surface of materials to enhance water resistance and surface gloss. Wax impregnation penetrates the material's pores, providing deeper protection by filling void spaces, thereby improving durability and resistance to wear. Key differences include the depth of wax application, with coating offering surface-level benefits and impregnation delivering structural reinforcement within the material.

Material Suitability for Wax Coating vs Wax Impregnation

Wax coating is highly suitable for materials with smooth, non-porous surfaces such as metals and plastics, providing a protective and glossy layer that enhances water resistance and aesthetics. Wax impregnation is better suited for porous materials like fabrics, wood, and paper, where the wax penetrates deeply to improve durability, moisture resistance, and flexibility without altering surface texture. Selecting the appropriate technique depends on the material's porosity and the desired balance between surface protection and internal reinforcement.

Application Processes Compared: Coating vs Impregnation

Wax coating involves applying a thin layer of wax on the surface of materials to provide a protective barrier against moisture, dust, and wear, commonly used in packaging and automotive industries. Wax impregnation saturates porous materials such as textiles or wood by forcing wax deep into the material's structure, enhancing water resistance and durability from within. The coating process is typically quicker and simpler, while impregnation offers longer-lasting protection by reinforcing the material at a microscopic level.

Performance and Durability Analysis

Wax coating provides a surface layer that enhances water repellency and gloss but may wear off over time, reducing its long-term effectiveness. Wax impregnation integrates wax into the substrate, offering deeper protection against moisture and corrosion, resulting in improved durability and sustained performance under harsh conditions. Studies indicate that impregnated wax treatments maintain superior barrier properties compared to coated wax, especially in abrasive or high-traffic environments.

Cost Implications: Wax Coating vs Wax Impregnation

Wax coating typically involves a surface layer application, resulting in lower initial material costs but may require frequent reapplication, increasing long-term expenses. Wax impregnation integrates wax deeper into the substrate, often leading to higher upfront costs due to more complex processing but offers enhanced durability and reduced maintenance costs over time. Evaluating cost implications between wax coating and wax impregnation demands consideration of product lifespan, frequency of reapplication, and overall performance requirements.

Environmental Impact of Each Method

Wax coating typically involves applying a surface layer of wax that can create a protective barrier but may lead to higher environmental waste due to the frequent need for reapplication and potential runoff. Wax impregnation, on the other hand, saturates the material, offering longer-lasting protection that reduces the frequency of treatments and minimizes wax consumption, resulting in a lower environmental footprint. Life cycle assessments highlight that wax impregnation often generates less waste and decreases chemical exposure risks compared to surface coating methods.

Typical Industries and Uses

Wax coating is extensively used in packaging industries for paperboard cartons, providing moisture resistance and enhanced gloss for food and beverage containers. Wax impregnation finds its primary application in the wood industry, improving durability and water repellency in products like furniture and flooring. Both methods serve key roles in textiles and automotive sectors, where surface protection and aesthetic enhancement are critical.

Pros and Cons of Wax Coating and Wax Impregnation

Wax coating provides a durable, uniform protective layer that enhances surface gloss and water resistance but can wear off over time and may require frequent reapplication. Wax impregnation penetrates the material for deeper protection against moisture and corrosion, improving durability without altering surface appearance; however, it is typically more complex and costly to apply. Choosing between wax coating and impregnation depends on the desired longevity, aesthetic outcome, and application environment.

How to Choose the Right Wax Treatment for Your Product

Selecting the appropriate wax treatment depends on your product's intended use and desired durability. Wax coating offers a surface layer that provides water resistance and a glossy finish, ideal for decorative items or short-term protection. Wax impregnation penetrates the material, enhancing flexibility and long-lasting moisture resistance, making it suitable for industrial applications or products exposed to harsh conditions.

Wax Coating vs Wax Impregnation Infographic

materialdif.com

materialdif.com