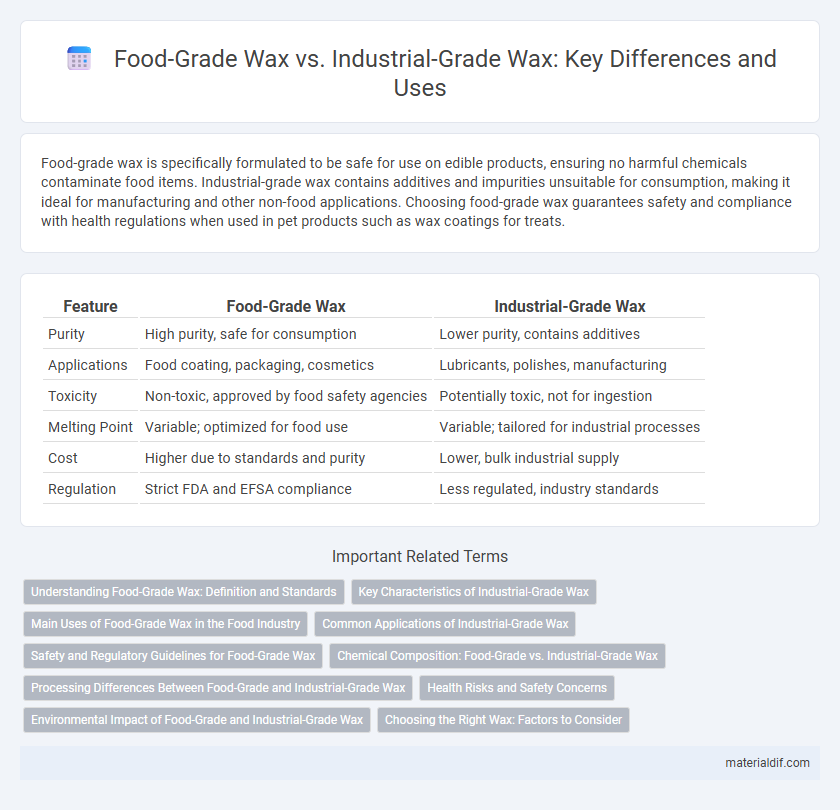

Food-grade wax is specifically formulated to be safe for use on edible products, ensuring no harmful chemicals contaminate food items. Industrial-grade wax contains additives and impurities unsuitable for consumption, making it ideal for manufacturing and other non-food applications. Choosing food-grade wax guarantees safety and compliance with health regulations when used in pet products such as wax coatings for treats.

Table of Comparison

| Feature | Food-Grade Wax | Industrial-Grade Wax |

|---|---|---|

| Purity | High purity, safe for consumption | Lower purity, contains additives |

| Applications | Food coating, packaging, cosmetics | Lubricants, polishes, manufacturing |

| Toxicity | Non-toxic, approved by food safety agencies | Potentially toxic, not for ingestion |

| Melting Point | Variable; optimized for food use | Variable; tailored for industrial processes |

| Cost | Higher due to standards and purity | Lower, bulk industrial supply |

| Regulation | Strict FDA and EFSA compliance | Less regulated, industry standards |

Understanding Food-Grade Wax: Definition and Standards

Food-grade wax is specifically formulated and approved for use in food products, meeting strict safety and purity standards set by regulatory bodies like the FDA and EFSA. It must be non-toxic, free from harmful contaminants, and suitable for direct contact with food items such as fruits, vegetables, and confectioneries. Compliance with these standards ensures food-grade wax maintains product freshness, enhances appearance, and extends shelf life without compromising consumer health.

Key Characteristics of Industrial-Grade Wax

Industrial-grade wax is characterized by its higher melting point, greater hardness, and lower purity compared to food-grade wax, making it suitable for applications such as coatings, adhesives, and lubrication. It often contains additives or impurities that enhance durability and resistance to chemicals, but render it unsafe for direct food contact. This wax variant provides superior structural stability and thermal resistance essential for heavy-duty industrial processes.

Main Uses of Food-Grade Wax in the Food Industry

Food-grade wax is primarily used for coating fruits and vegetables to extend shelf life by reducing moisture loss and protecting against pathogens. It also serves as a glazing agent in confections and a coating for cheese to prevent mold growth during aging. Unlike industrial-grade wax, food-grade wax complies with stringent FDA regulations ensuring its safety for direct contact with edible products.

Common Applications of Industrial-Grade Wax

Industrial-grade wax is extensively used in automotive manufacturing for mold release, lubrication, and corrosion protection due to its high melting point and durability. It also finds applications in the production of candles, crayons, and coatings for packaging materials where strong adhesion and weather resistance are required. Furthermore, industrial waxes are critical in electrical insulation, metalworking, and as additives in rubber and plastics industries for enhanced performance.

Safety and Regulatory Guidelines for Food-Grade Wax

Food-grade wax complies with strict FDA and EFSA regulations ensuring it is safe for direct contact with food, preventing contamination and adverse health effects. It undergoes rigorous purity testing and must contain non-toxic additives, whereas industrial-grade wax lacks these safety certifications and often contains harmful impurities. Using food-grade wax protects consumers and meets mandatory safety standards for packaging, coating, and preservation applications in the food industry.

Chemical Composition: Food-Grade vs. Industrial-Grade Wax

Food-grade waxes are composed of purified hydrocarbons and natural resins that meet strict safety standards for human consumption, ensuring non-toxicity and minimal chemical additives. Industrial-grade waxes often contain synthetic compounds and additional chemical fillers that enhance durability but may include substances harmful if ingested. The chemical purity and absence of contaminants in food-grade wax make it suitable for coating fruits, vegetables, and confectionery, while industrial-grade waxes are primarily used in manufacturing and packaging applications where toxicity is less critical.

Processing Differences Between Food-Grade and Industrial-Grade Wax

Food-grade wax undergoes stringent purification processes to remove impurities and contaminants, ensuring it meets safety standards for direct or indirect food contact. Industrial-grade wax, processed with fewer purification steps, may contain additives or residues unsuitable for consumption. The critical differentiation lies in filtration, bleaching, and testing protocols that tailor food-grade wax for hygiene and non-toxicity.

Health Risks and Safety Concerns

Food-grade wax is specifically formulated to meet stringent safety standards set by regulatory bodies such as the FDA, minimizing health risks when used on edible products like fruits and candies. Industrial-grade wax often contains additives and chemicals that can be toxic if ingested, posing significant health hazards if mistakenly used in food applications. Ensuring the correct grade of wax is crucial for consumer safety, as food-grade wax provides a protective, non-toxic barrier, while industrial wax should be strictly limited to non-food uses due to potential contamination and toxicity.

Environmental Impact of Food-Grade and Industrial-Grade Wax

Food-grade waxes, often derived from natural or biodegradable materials like beeswax and carnauba, have a lower environmental impact compared to industrial-grade waxes, which typically contain synthetic polymers and hydrocarbons that can persist in ecosystems. The biodegradability of food-grade wax reduces soil and water contamination, promoting safer disposal and composting processes. Industrial-grade waxes, due to their chemical composition and resistance to degradation, pose greater risks of long-term environmental pollution and bioaccumulation.

Choosing the Right Wax: Factors to Consider

Food-grade wax is specifically formulated to meet safety standards for direct contact with food, ensuring non-toxicity and compliance with FDA regulations. Industrial-grade wax offers enhanced durability and abrasion resistance but may contain additives unsafe for consumption. When choosing the right wax, prioritize food safety certifications, purity levels, and intended application to avoid contamination and ensure regulatory compliance.

Food-Grade Wax vs Industrial-Grade Wax Infographic

materialdif.com

materialdif.com