Hot wax dipping involves melting wax to a liquid state before submerging the object, ensuring even coverage and a smooth finish that hardens quickly. Cold wax application uses solid wax applied directly without heating, offering a textured, more rustic appearance but requiring longer curing time. Each method suits different artistic or protective purposes based on desired texture, durability, and ease of use.

Table of Comparison

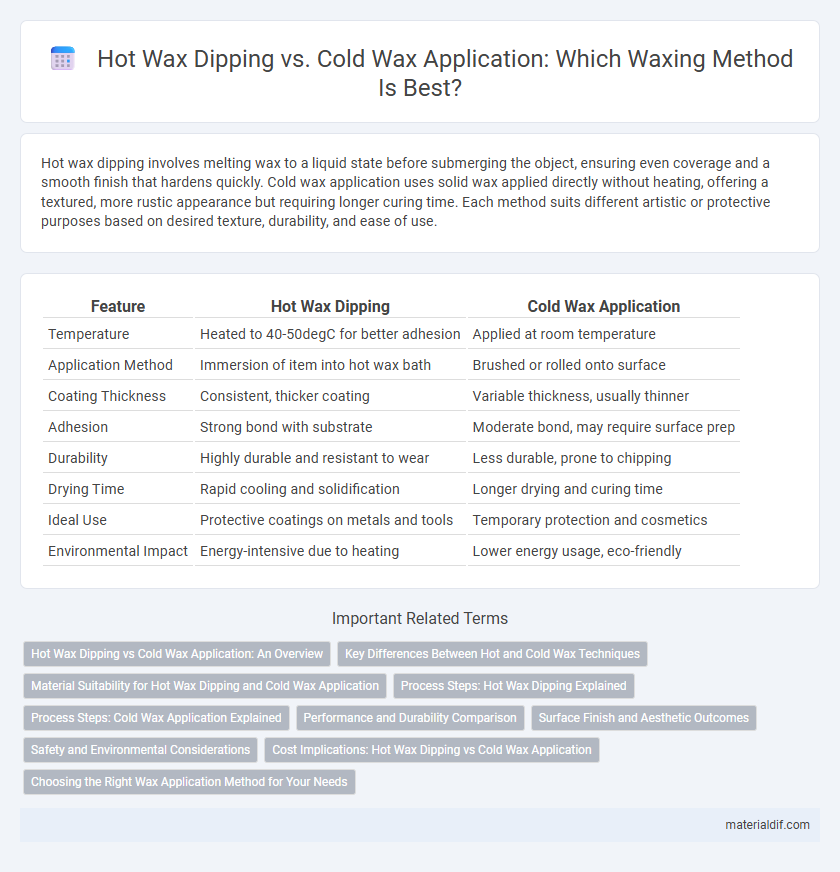

| Feature | Hot Wax Dipping | Cold Wax Application |

|---|---|---|

| Temperature | Heated to 40-50degC for better adhesion | Applied at room temperature |

| Application Method | Immersion of item into hot wax bath | Brushed or rolled onto surface |

| Coating Thickness | Consistent, thicker coating | Variable thickness, usually thinner |

| Adhesion | Strong bond with substrate | Moderate bond, may require surface prep |

| Durability | Highly durable and resistant to wear | Less durable, prone to chipping |

| Drying Time | Rapid cooling and solidification | Longer drying and curing time |

| Ideal Use | Protective coatings on metals and tools | Temporary protection and cosmetics |

| Environmental Impact | Energy-intensive due to heating | Lower energy usage, eco-friendly |

Hot Wax Dipping vs Cold Wax Application: An Overview

Hot wax dipping involves submerging the skin into a heated wax bath, which hardens quickly for a smooth, long-lasting finish ideal for hair removal or skincare treatments. Cold wax application uses pre-warmed wax applied with a spatula, offering a less messy, portable alternative but with potentially reduced adhesion and shorter efficacy in hair removal. Both methods vary in temperature control, application technique, and outcome durability, catering to different preferences and skin types.

Key Differences Between Hot and Cold Wax Techniques

Hot wax dipping involves melting wax to a liquid state before immersing the skin, allowing for deep pore penetration and longer-lasting hair removal, while cold wax application uses pre-coated strips applied directly to the skin, offering quicker use but potentially less effective on coarse hair. Hot wax adheres only to the hair, reducing skin irritation and making it suitable for sensitive areas, whereas cold wax often sticks to the skin surface, which can increase discomfort. The temperature control in hot wax requires more preparation and safety precautions, contrasting with the convenience and portability of cold wax strips.

Material Suitability for Hot Wax Dipping and Cold Wax Application

Hot wax dipping is ideal for materials like fabrics, metal, and certain ceramics that can withstand high temperatures without damage, ensuring a durable and even coating. Cold wax application suits delicate surfaces such as wood, paper, and painted objects that may deform or discolor under heat, allowing for precise control and layering. Selecting the appropriate wax method depends on the thermal resistance and texture of the material to achieve optimal adhesion and finish quality.

Process Steps: Hot Wax Dipping Explained

Hot wax dipping involves melting beeswax until it reaches a liquid state, then fully submerging the object into the hot wax to create a thick, even coating. The process requires maintaining a controlled temperature of around 140-160degF (60-71degC) to ensure optimal flow and adhesion. After dipping, the object is allowed to cool and harden, forming a durable, protective layer ideal for sealing and preserving.

Process Steps: Cold Wax Application Explained

Cold wax application involves applying a thin layer of wax paste directly onto the skin, followed by placing a cloth strip over the wax and pressing firmly. The strip is swiftly pulled off in the opposite direction of hair growth, removing hair from the root with minimal discomfort. This method is favored for its ease of use, reduced risk of burns, and effectiveness on sensitive areas like the face and bikini line.

Performance and Durability Comparison

Hot wax dipping creates a thicker, more uniform coating that offers superior corrosion resistance and durability compared to cold wax application. The high-temperature process ensures better adhesion and penetration into surfaces, resulting in enhanced performance under extreme conditions. Cold wax application provides quicker, thinner layers suitable for short-term protection but lacks the long-lasting robustness of hot wax dipping.

Surface Finish and Aesthetic Outcomes

Hot wax dipping creates a smooth, glossy surface finish by evenly melting and bonding the wax to the material, enhancing durability and visual appeal. Cold wax application often results in a matte or textured surface, providing a rustic or handcrafted aesthetic but with less uniform coverage. The choice between hot and cold wax significantly influences the final appearance, with hot wax favored for sleek, polished outcomes, while cold wax suits natural, artisanal finishes.

Safety and Environmental Considerations

Hot wax dipping involves immersing items in molten wax, which requires careful temperature control to prevent burns and fire hazards, while cold wax application minimizes these risks due to its lower temperature use. From an environmental perspective, hot wax processes may consume more energy and produce higher emissions compared to cold wax methods, which often utilize eco-friendly formulations and reduce waste. Choosing between the two depends on balancing safety protocols and environmental impact, favoring cold wax for safer handling and greener production.

Cost Implications: Hot Wax Dipping vs Cold Wax Application

Hot wax dipping typically involves higher upfront costs due to the need for specialized equipment like wax warmers and heaters, as well as the continuous energy consumption required to maintain the wax temperature. Cold wax application, in contrast, generally has lower initial expenses and reduced energy costs since it doesn't require heating equipment, making it more budget-friendly for small-scale or home use. Long-term operational expenses for hot wax dipping may be elevated, but the process often yields less product waste compared to cold wax, potentially balancing cost implications over time.

Choosing the Right Wax Application Method for Your Needs

Hot wax dipping provides deeper hair removal by heating wax to open pores and effectively grip coarse hair, making it ideal for sensitive skin and longer-lasting results. Cold wax application offers a quicker, less messy alternative suitable for small areas or delicate skin, but may require more frequent treatments due to less thorough hair removal. Selecting the right wax method depends on hair type, skin sensitivity, and desired treatment duration for optimal comfort and effectiveness.

Hot wax dipping vs Cold wax application Infographic

materialdif.com

materialdif.com