Regenerated cellulose, often derived from natural cellulose sources like wood pulp, undergoes chemical processing to create fibers with enhanced strength and uniformity, making it ideal for textiles and packaging. Pure cellulose, in its natural form, retains more of its original molecular structure and is used in applications requiring purity and biodegradability, such as pharmaceuticals and food additives. Understanding the differences in processing and properties between regenerated and pure cellulose helps optimize their application in sustainable materials.

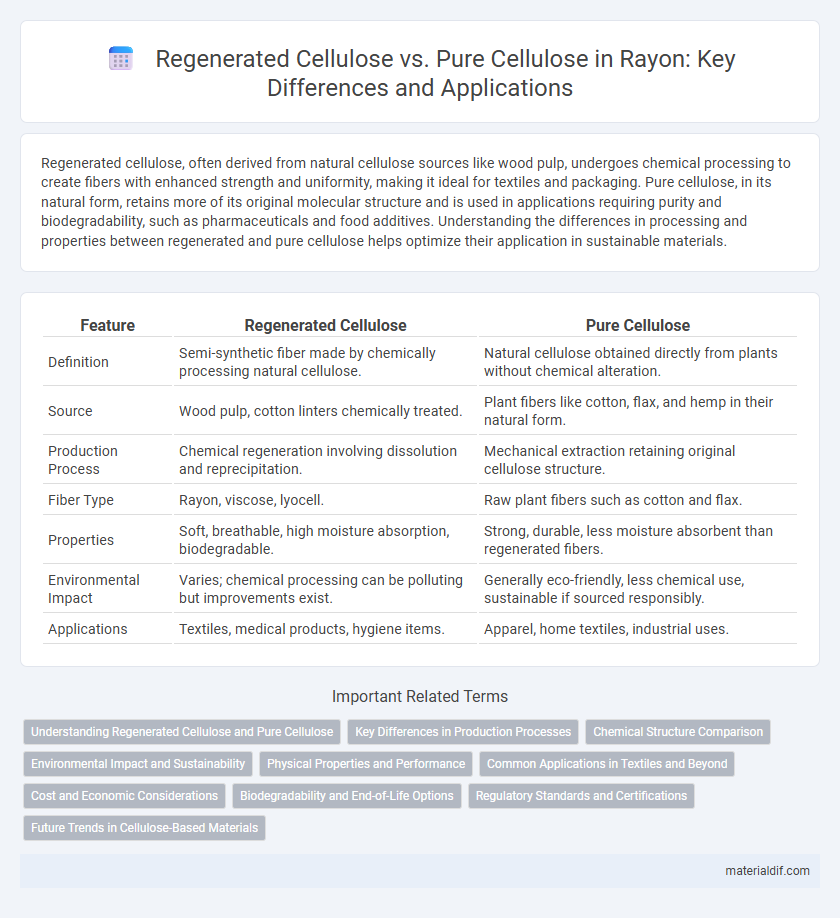

Table of Comparison

| Feature | Regenerated Cellulose | Pure Cellulose |

|---|---|---|

| Definition | Semi-synthetic fiber made by chemically processing natural cellulose. | Natural cellulose obtained directly from plants without chemical alteration. |

| Source | Wood pulp, cotton linters chemically treated. | Plant fibers like cotton, flax, and hemp in their natural form. |

| Production Process | Chemical regeneration involving dissolution and reprecipitation. | Mechanical extraction retaining original cellulose structure. |

| Fiber Type | Rayon, viscose, lyocell. | Raw plant fibers such as cotton and flax. |

| Properties | Soft, breathable, high moisture absorption, biodegradable. | Strong, durable, less moisture absorbent than regenerated fibers. |

| Environmental Impact | Varies; chemical processing can be polluting but improvements exist. | Generally eco-friendly, less chemical use, sustainable if sourced responsibly. |

| Applications | Textiles, medical products, hygiene items. | Apparel, home textiles, industrial uses. |

Understanding Regenerated Cellulose and Pure Cellulose

Regenerated cellulose is produced by chemically dissolving natural cellulose fibers and reforming them into a new fiber structure, resulting in materials like rayon that combine natural properties with enhanced flexibility and softness. Pure cellulose consists of untreated, naturally occurring cellulose polymers found in plant cell walls, characterized by high crystallinity and rigidity. Understanding the differences involves recognizing that regenerated cellulose offers improved versatility for textiles, while pure cellulose maintains the original structural integrity of plant fibers.

Key Differences in Production Processes

Regenerated cellulose is produced by chemically transforming natural cellulose through processes like the viscose or lyocell methods, involving dissolution and reformation into fibers, whereas pure cellulose refers to cellulose extracted in its natural polymer form without significant chemical alteration. The production of regenerated cellulose requires reagents such as carbon disulfide or N-Methylmorpholine N-oxide, which break down cellulose into a soluble form before spinning, contrasting with the minimal processing of pure cellulose cellulose fibers directly extracted from plant sources. These differences in chemical treatment and fiber formation impact fiber properties, sustainability profiles, and applications in textiles and nonwoven materials.

Chemical Structure Comparison

Regenerated cellulose, derived from chemically processed natural cellulose, retains the fundamental b-1,4-glycosidic linkages but undergoes transformation through dissolution and regeneration, altering its crystalline structure from cellulose I to cellulose II. Pure cellulose consists of native cellulose molecules with tightly packed crystalline regions and high polymerization degree, contributing to its rigidity and insolubility. The chemical modification in regenerated cellulose disrupts hydrogen bonding, resulting in enhanced solubility and flexibility compared to pure cellulose's unaltered polymer chains.

Environmental Impact and Sustainability

Regenerated cellulose, such as rayon, is derived from natural cellulose fibers chemically processed to create versatile textiles, but the production often involves harmful chemicals impacting the environment. Pure cellulose, sourced directly from plant fibers like cotton or linen, tends to have a lower ecological footprint due to minimal chemical treatment and better biodegradability. Sustainable practices in cellulose sourcing and advancements in closed-loop production systems are crucial to minimizing environmental harm and promoting eco-friendly textile solutions.

Physical Properties and Performance

Regenerated cellulose, such as rayon, exhibits enhanced flexibility and moisture absorption compared to pure cellulose due to its controlled polymer structure and manufacturing process. The physical properties of regenerated cellulose fibers, including tensile strength and elongation, often surpass those of pure cellulose, offering improved durability and comfort in textile applications. Performance-wise, regenerated cellulose maintains better dimensional stability and dye affinity, making it a preferred choice for fashion and industrial fabrics over pure cellulose.

Common Applications in Textiles and Beyond

Regenerated cellulose fibers, such as rayon, are widely used in textiles for their softness, breathability, and versatility, making them ideal for clothing, upholstery, and home textiles. Pure cellulose, derived directly from natural sources like cotton or wood pulp, serves as the raw material for producing various textiles, paper products, and biodegradable packaging. Beyond textiles, regenerated cellulose finds applications in medical dressings, hygiene products, and films due to its biocompatibility and moisture management properties.

Cost and Economic Considerations

Regenerated cellulose like rayon is generally more cost-effective to produce than pure cellulose due to the lower processing expenses and availability of raw materials derived from wood pulp and cotton linters. The chemical regeneration process used in rayon manufacturing enables large-scale production at reduced costs compared to the isolation and purification of pure cellulose, which involves more complex and energy-intensive steps. Economic viability of regenerated cellulose fabrics is enhanced by their versatility and lower raw material costs, making them popular in textile and industrial applications.

Biodegradability and End-of-Life Options

Regenerated cellulose, such as rayon, is derived from purified cellulose fibers that have been chemically processed, making it biodegradable and suitable for various end-of-life options including composting and biodegradation in natural environments. Pure cellulose, found in materials like cotton or wood pulp, is naturally biodegradable but less versatile in industrial applications compared to regenerated forms. Both types break down into organic matter, but regenerated cellulose offers enhanced performance while maintaining environmental compatibility in disposal processes.

Regulatory Standards and Certifications

Regenerated cellulose, such as rayon, undergoes chemical processing that subjects it to stringent regulatory standards including OEKO-TEX(r) Standard 100 and REACH compliance, ensuring minimal harmful substances and environmental impact. Pure cellulose fibers, derived directly from wood pulp without extensive chemical alteration, are often certified by FSC (Forest Stewardship Council) and USDA Organic standards, emphasizing sustainable sourcing and biodegradability. Both material types require compliance with international safety and environmental certifications to ensure product safety and market acceptance.

Future Trends in Cellulose-Based Materials

Future trends in cellulose-based materials emphasize the development of regenerated cellulose fibers like rayon, which offer enhanced biodegradability and sustainable production processes compared to pure cellulose. Innovations in chemical treatments and eco-friendly solvents are driving the shift towards more efficient and less polluting methods for producing regenerated cellulose, aligning with global demands for renewable textiles. Emerging research on modifying cellulose molecular structures aims to improve mechanical strength and functionality, expanding applications beyond traditional textiles to advanced bioplastics and smart materials.

Regenerated Cellulose vs Pure Cellulose Infographic

materialdif.com

materialdif.com