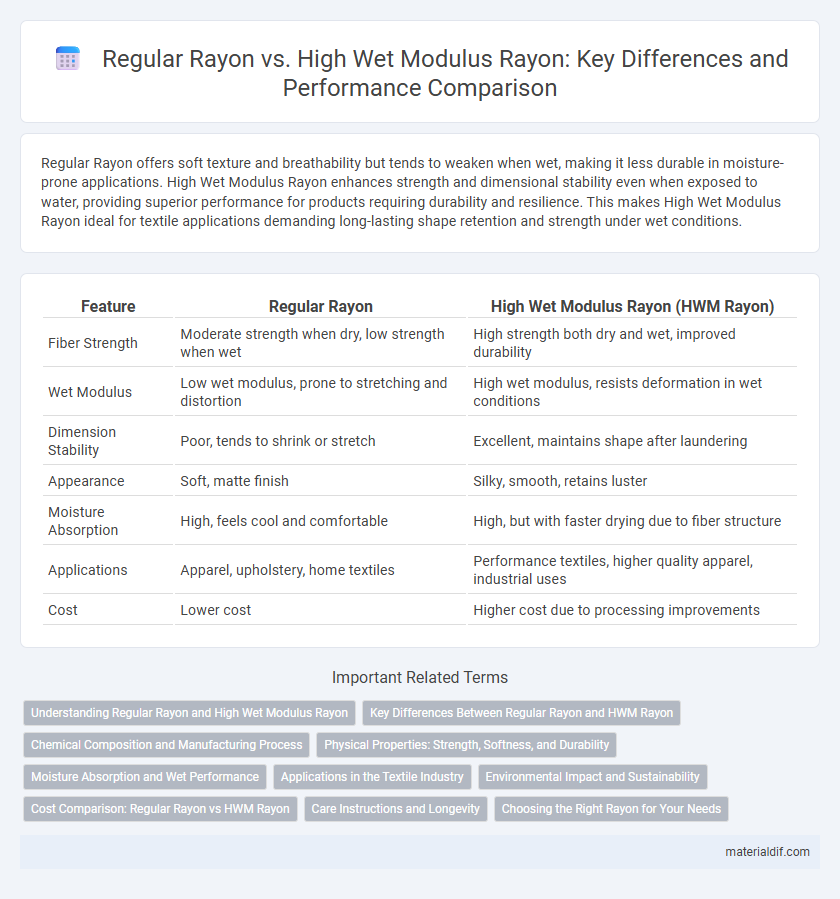

Regular Rayon offers soft texture and breathability but tends to weaken when wet, making it less durable in moisture-prone applications. High Wet Modulus Rayon enhances strength and dimensional stability even when exposed to water, providing superior performance for products requiring durability and resilience. This makes High Wet Modulus Rayon ideal for textile applications demanding long-lasting shape retention and strength under wet conditions.

Table of Comparison

| Feature | Regular Rayon | High Wet Modulus Rayon (HWM Rayon) |

|---|---|---|

| Fiber Strength | Moderate strength when dry, low strength when wet | High strength both dry and wet, improved durability |

| Wet Modulus | Low wet modulus, prone to stretching and distortion | High wet modulus, resists deformation in wet conditions |

| Dimension Stability | Poor, tends to shrink or stretch | Excellent, maintains shape after laundering |

| Appearance | Soft, matte finish | Silky, smooth, retains luster |

| Moisture Absorption | High, feels cool and comfortable | High, but with faster drying due to fiber structure |

| Applications | Apparel, upholstery, home textiles | Performance textiles, higher quality apparel, industrial uses |

| Cost | Lower cost | Higher cost due to processing improvements |

Understanding Regular Rayon and High Wet Modulus Rayon

Regular rayon is a semi-synthetic fiber made from regenerated cellulose, known for its softness, breathability, and versatility in textiles but exhibits lower wet strength and dimensional stability when exposed to moisture. High Wet Modulus (HWM) rayon, an advanced type of rayon, offers significantly enhanced wet strength and durability due to improved molecular orientation and crystallinity during production, making it more resistant to stretching and shrinking in wet conditions. Understanding the structural differences highlights HWM rayon's superior performance in applications requiring moisture resistance and greater mechanical stability compared to regular rayon.

Key Differences Between Regular Rayon and HWM Rayon

Regular Rayon typically has lower tensile strength and loses significant durability when wet, whereas High Wet Modulus (HWM) Rayon maintains enhanced strength and dimensional stability under wet conditions. HWM Rayon undergoes a modified viscose process resulting in higher molecular orientation, which imparts superior wet modulus and improved wrinkle resistance compared to regular Rayon. The key differences include HWM Rayon's increased wet strength, better resilience, and higher durability, making it suitable for applications requiring frequent laundering and sustained mechanical stress.

Chemical Composition and Manufacturing Process

Regular Rayon is primarily composed of regenerated cellulose derived from wood pulp treated with sodium hydroxide and carbon disulfide in the viscose process, resulting in fibers with moderate strength and elasticity. High Wet Modulus (HWM) Rayon undergoes an advanced alkali treatment and increased cellulose aging during manufacturing, enhancing its molecular orientation and crystallinity, which significantly improves its wet strength and dimensional stability. The chemical modifications and refined processing steps in HWM Rayon production lead to fibers that exhibit superior tenacity and resistance to deformation compared to regular Rayon.

Physical Properties: Strength, Softness, and Durability

High Wet Modulus (HWM) Rayon exhibits significantly greater tensile strength when wet compared to Regular Rayon, making it more durable in humid or damp conditions. Both types maintain excellent softness and smooth texture, but HWM Rayon offers enhanced resilience, reducing fabric deformation and shrinkage. The improved physical properties of HWM Rayon provide superior durability without compromising the comfort and drape characteristic of Regular Rayon.

Moisture Absorption and Wet Performance

Regular Rayon exhibits high moisture absorption due to its hydrophilic cellulose structure, making it prone to swelling and reduced strength when wet. High Wet Modulus (HWM) Rayon, engineered with optimized molecular orientation and cross-linking, maintains superior tensile strength and dimensional stability under wet conditions. This enhanced wet performance allows HWM Rayon to outperform Regular Rayon in applications requiring durability and resilience in moist environments.

Applications in the Textile Industry

Regular rayon offers excellent moisture absorption and a soft texture, making it ideal for apparel, home textiles, and upholstery where comfort and breathability are prioritized. High Wet Modulus (HWM) rayon provides superior strength and dimensional stability when wet, which enhances durability and performance in industrial textiles, sportswear, and workwear applications. The choice between regular and HWM rayon hinges on specific textile requirements such as tensile strength, elasticity, and moisture handling in end-use products.

Environmental Impact and Sustainability

Regular rayon production involves significant water and chemical usage, contributing to deforestation and water pollution, which raises environmental concerns. High Wet Modulus (HWM) rayon offers improved fiber strength and durability, reducing fabric waste and extending product lifespan, thereby enhancing sustainability. Innovations in closed-loop processing for HWM rayon minimize harmful effluents and resource consumption, making it a more eco-friendly alternative to conventional rayon.

Cost Comparison: Regular Rayon vs HWM Rayon

Regular Rayon typically costs less than High Wet Modulus (HWM) Rayon due to its simpler manufacturing process and lower tensile strength properties. HWM Rayon offers superior wet strength and dimensional stability, justifying its higher price in applications demanding durability and performance. Cost differences are significant for industries evaluating material efficiency against budget constraints in textiles and industrial uses.

Care Instructions and Longevity

Regular rayon requires gentle hand washing or dry cleaning to maintain fabric integrity, as it tends to weaken and lose shape when wet. High Wet Modulus (HWM) rayon, engineered for enhanced wet strength, allows for more durable machine washing and better resistance to shrinkage and deformation. The superior fiber structure of HWM rayon extends garment longevity, making it a preferred choice for frequent use and rigorous care conditions.

Choosing the Right Rayon for Your Needs

Regular Rayon offers smooth texture and breathability ideal for casual wear and lightweight apparel, while High Wet Modulus (HWM) Rayon provides superior strength and durability when wet, making it more suitable for activewear and heavy-duty textiles. HWM Rayon's enhanced wet and dry tensile strength results from a modified fabrication process, ensuring long-lasting performance in moisture-prone environments. Selecting between Regular and HWM Rayon depends on balancing comfort needs with durability requirements for intended garment use.

Regular Rayon vs High Wet Modulus Rayon Infographic

materialdif.com

materialdif.com