Rayon fabric is a versatile textile made from regenerated cellulose fibers, offering a smooth texture and excellent drape, ideal for clothing and home textiles. Rayon fiber refers to the raw material extracted and processed from natural sources like wood pulp, which is then spun into threads before being woven or knitted into fabric. Understanding the distinction between rayon fiber and rayon fabric is crucial for appreciating the manufacturing process and the fabric's final properties such as breathability, softness, and durability.

Table of Comparison

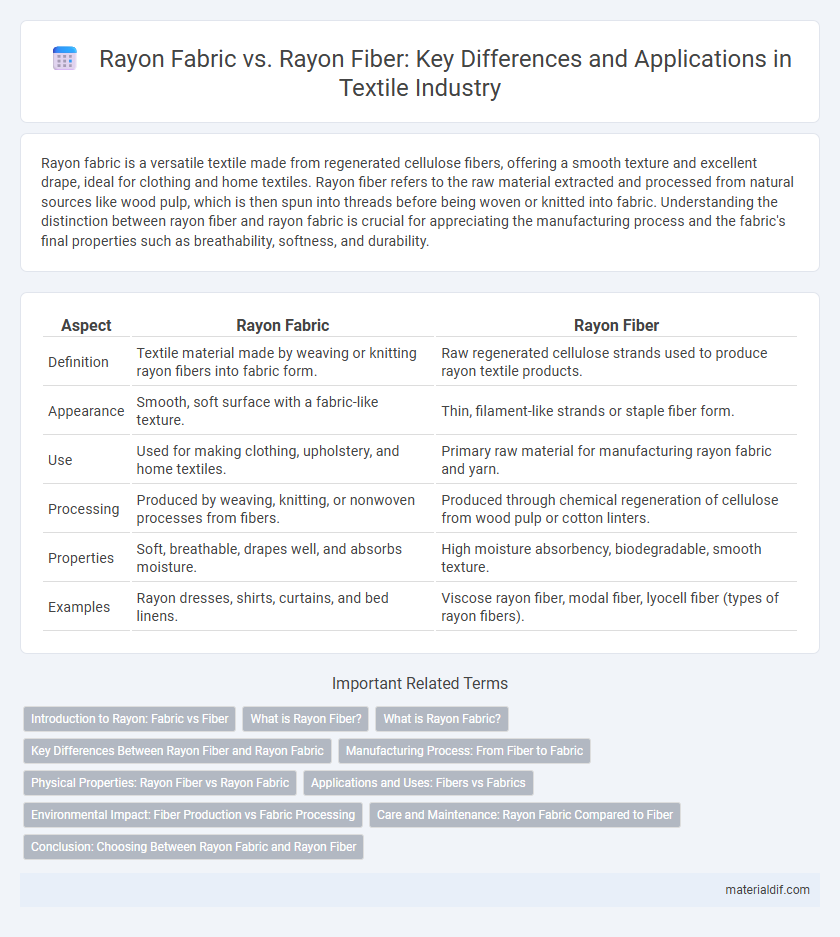

| Aspect | Rayon Fabric | Rayon Fiber |

|---|---|---|

| Definition | Textile material made by weaving or knitting rayon fibers into fabric form. | Raw regenerated cellulose strands used to produce rayon textile products. |

| Appearance | Smooth, soft surface with a fabric-like texture. | Thin, filament-like strands or staple fiber form. |

| Use | Used for making clothing, upholstery, and home textiles. | Primary raw material for manufacturing rayon fabric and yarn. |

| Processing | Produced by weaving, knitting, or nonwoven processes from fibers. | Produced through chemical regeneration of cellulose from wood pulp or cotton linters. |

| Properties | Soft, breathable, drapes well, and absorbs moisture. | High moisture absorbency, biodegradable, smooth texture. |

| Examples | Rayon dresses, shirts, curtains, and bed linens. | Viscose rayon fiber, modal fiber, lyocell fiber (types of rayon fibers). |

Introduction to Rayon: Fabric vs Fiber

Rayon fiber is a regenerated cellulose fiber derived from natural sources like wood pulp, serving as the raw material used to produce rayon fabric through processes such as spinning and weaving. Rayon fabric refers to the finished textile material created from rayon fibers, known for its smooth texture, breathability, and versatility in fashion and upholstery applications. Understanding the distinction between rayon fiber as a manufactured filament and rayon fabric as the end product is crucial for textile manufacturing, garment production, and consumer use.

What is Rayon Fiber?

Rayon fiber is a semi-synthetic fiber made from regenerated cellulose derived from natural sources like wood pulp or bamboo. It exhibits properties similar to natural fibers such as cotton, including breathability, softness, and moisture absorption, making it ideal for textile production. Rayon fabric, produced by weaving or knitting rayon fibers, offers a smooth texture and drapes well, commonly used in clothing and home textiles.

What is Rayon Fabric?

Rayon fabric is a versatile textile made from regenerated cellulose fibers derived from natural sources like wood pulp. It imitates the feel and texture of natural fibers such as cotton, silk, or wool, providing a soft, breathable, and comfortable material suitable for clothing and home textiles. Unlike raw rayon fiber, which is the basic filament, rayon fabric undergoes spinning and weaving processes to transform fibers into usable fabric for various applications.

Key Differences Between Rayon Fiber and Rayon Fabric

Rayon fiber is the raw, regenerated cellulose material derived from wood pulp, whereas rayon fabric is the woven or knitted textile produced from these fibers. The key differences lie in their form and application: rayon fiber exists as a spun thread used for yarn production, while rayon fabric refers to the finished textile product used in apparel and home textiles. Understanding these distinctions highlights how rayon fibers are the essential building blocks, and rayon fabric represents the final usable material in the textile industry.

Manufacturing Process: From Fiber to Fabric

Rayon fiber is produced through a chemical process that converts cellulose from wood pulp into a viscous solution, which is then extruded into filaments and solidified into fiber. The manufacturing of rayon fabric involves spinning these regenerated fibers into yarn, followed by weaving or knitting to create fabric with a smooth texture and good drape. This transformation from fiber to fabric highlights the complex production stages that influence the final quality and characteristics of rayon textiles.

Physical Properties: Rayon Fiber vs Rayon Fabric

Rayon fiber exhibits high tensile strength and excellent moisture absorbency, making it soft, breathable, and comfortable against the skin. In contrast, rayon fabric, woven or knitted from these fibers, demonstrates varying physical properties depending on the fabric construction, such as drape, texture, and durability. While rayon fiber is the fundamental raw material with inherent strength and flexibility, rayon fabric provides the final tactile experience and wear performance in apparel and home textiles.

Applications and Uses: Fibers vs Fabrics

Rayon fiber serves as the raw material primarily used in textile manufacturing, ideal for spinning into yarns for clothing, upholstery, and industrial uses due to its softness and breathability. Rayon fabric, derived from these fibers, is widely applied in fashion apparel, home textiles, and accessories because of its smooth texture and versatility in dyeing. The fiber's flexibility supports blending with other fibers for enhanced durability, while the fabric's finished form offers a wide range of styles and functions suitable for consumer markets.

Environmental Impact: Fiber Production vs Fabric Processing

Rayon fiber production involves extensive use of chemical solvents such as carbon disulfide, which poses significant environmental hazards and requires careful waste management to minimize pollution. In contrast, rayon fabric processing contributes to environmental strain through energy-intensive dyeing and finishing techniques that release residual chemicals into water systems. Evaluating the environmental impact of rayon necessitates understanding that fiber production primarily affects air and soil quality due to chemical emissions, while fabric processing chiefly influences water quality through effluent discharge.

Care and Maintenance: Rayon Fabric Compared to Fiber

Rayon fabric requires careful washing in cold water and gentle handling to prevent shrinkage and distortion, while rayon fiber, used in raw or processed form, demands more controlled conditions during manufacturing rather than daily care. Fabric made from rayon fibers is prone to wrinkles and may weaken when wet, so air drying and avoiding high heat are essential for longevity. Maintaining rayon fabric involves delicate cleaning techniques compared to the initial fiber stage, where industrial processes largely dictate quality and durability.

Conclusion: Choosing Between Rayon Fabric and Rayon Fiber

Rayon fabric offers versatility and comfort suitable for finished garments, while rayon fiber provides raw material flexibility for diverse textile production. Selecting between rayon fabric and rayon fiber depends on application needs, with fabric ready for immediate use and fiber ideal for customization in manufacturing. Understanding this distinction ensures optimal use in fashion design, textile engineering, and industrial applications.

Rayon Fabric vs Rayon Fiber Infographic

materialdif.com

materialdif.com