Rayon pilling occurs more frequently than cotton pilling due to its weaker fiber strength and lower resistance to abrasion. Cotton, being a natural fiber with stronger staple length, tends to pill less and maintains a smoother surface over time. Proper fabric care can minimize pilling for both rayon and cotton, but rayon requires extra caution to preserve its quality.

Table of Comparison

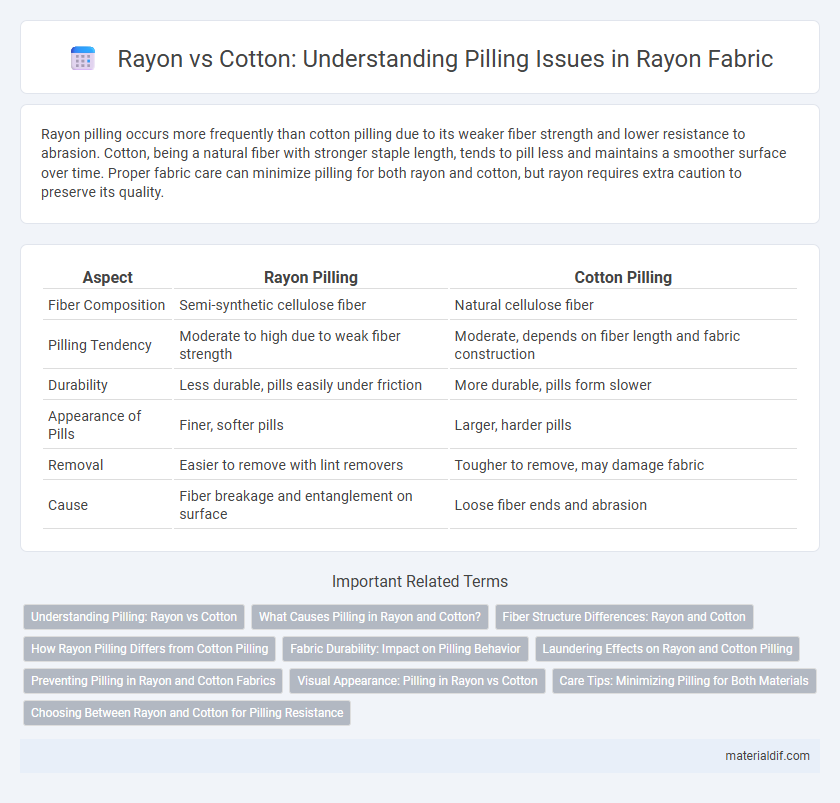

| Aspect | Rayon Pilling | Cotton Pilling |

|---|---|---|

| Fiber Composition | Semi-synthetic cellulose fiber | Natural cellulose fiber |

| Pilling Tendency | Moderate to high due to weak fiber strength | Moderate, depends on fiber length and fabric construction |

| Durability | Less durable, pills easily under friction | More durable, pills form slower |

| Appearance of Pills | Finer, softer pills | Larger, harder pills |

| Removal | Easier to remove with lint removers | Tougher to remove, may damage fabric |

| Cause | Fiber breakage and entanglement on surface | Loose fiber ends and abrasion |

Understanding Pilling: Rayon vs Cotton

Pilling occurs when fibers break and form small balls on fabric surfaces, with rayon being more prone to pilling due to its weaker, shorter artificial fibers compared to the natural, longer staple fibers of cotton. Rayon pills can appear faster and more noticeably because the fibers have less resilience and tensile strength, whereas cotton typically resists pilling better due to its durable cellulose structure. Understanding the fiber characteristics helps in selecting appropriate fabric care techniques to minimize pilling and extend garment lifespan.

What Causes Pilling in Rayon and Cotton?

Pilling in rayon occurs due to its weak fiber strength and smooth surface, causing fibers to break and tangle easily under friction. Cotton pilling arises from shorter staple fibers that break and form pills as they are rubbed during wear or washing. Both fabrics develop pills when surface fibers loosen and entangle, but rayon is more prone due to its artificial fiber structure compared to natural cotton.

Fiber Structure Differences: Rayon and Cotton

Rayon fibers are chemically regenerated cellulose with a smooth, uniform filament structure that reduces surface friction and lowers the tendency to pill compared to cotton's natural, twisted, and irregular fiber structure. Cotton fibers have a convoluted surface and shorter staple length, creating more fiber ends that protrude and catch during wear, increasing pilling potential. The distinct molecular alignment and smoother surface of rayon contribute to less fiber entanglement and pilling than the broken, fuzzy surface typical of cotton.

How Rayon Pilling Differs from Cotton Pilling

Rayon pilling occurs due to its semi-synthetic cellulose fibers, which tend to break and form pills more easily compared to natural cotton fibers that have a stronger fiber strength and smoother surface. Unlike cotton pilling, which results from fiber ends protruding and tangling on the fabric surface, rayon pills often form because of weaker fiber cohesion and increased abrasion sensitivity. This difference in fiber structure means that rayon fabrics generally experience more noticeable pilling under wear and washing conditions than cotton fabrics.

Fabric Durability: Impact on Pilling Behavior

Rayon fabric, known for its smooth texture and drape, generally exhibits higher pilling susceptibility than cotton due to its cellulose-based regenerated fibers, which are weaker and less resilient under abrasion. Cotton fibers, being naturally longer and staple-based, offer superior fabric durability that resists pilling more effectively during regular wear and washing cycles. The impact on pilling behavior is significant, as rayon's lower fiber strength leads to more frequent fiber breakage and surface fuzz, whereas cotton maintains structural integrity longer, reducing visible pills.

Laundering Effects on Rayon and Cotton Pilling

Rayon fibers tend to pill more noticeably than cotton due to their weaker fiber structure and lower resilience during laundering. Frequent washing and agitation cause rayon to break down and form pills, whereas cotton's stronger cellulose fibers resist pilling better under similar laundering conditions. Proper care, including gentle washing cycles and low spin speeds, can significantly reduce pilling on rayon fabrics compared to routine laundering of cotton.

Preventing Pilling in Rayon and Cotton Fabrics

Rayon and cotton fabrics are both prone to pilling, which can be minimized by selecting high-quality fibers and employing proper fabric finishes. Preventing pilling in rayon involves applying anti-pilling treatments during manufacturing and using gentle washing methods with mild detergents and cold water. For cotton, maintaining fabric strength through mercerization and avoiding abrasive washing cycles reduces fiber breakage and pill formation.

Visual Appearance: Pilling in Rayon vs Cotton

Rayon pilling tends to form smaller, less noticeable pills that blend with the fabric's sheen, maintaining a smoother visual appearance compared to cotton. Cotton pilling often results in larger, more conspicuous pills that disrupt the fabric's texture and diminish its overall look. The lustrous quality of rayon fibers helps minimize the contrast between pills and fabric, preserving a cleaner, more polished surface.

Care Tips: Minimizing Pilling for Both Materials

To minimize pilling on rayon and cotton fabrics, wash garments inside out on a gentle cycle using cold water and mild detergent to reduce friction. Avoid high heat when drying by opting for air drying or a low-heat setting to maintain fiber integrity and prevent fabric damage. Using a fabric softener or a mesh laundry bag helps protect fibers during washing, while prompt removal from the dryer minimizes wrinkles and additional abrasion.

Choosing Between Rayon and Cotton for Pilling Resistance

Rayon typically exhibits less pilling compared to cotton due to its smoother, regenerated cellulose fibers that resist fuzz formation. Cotton's natural short staple fibers tend to loosen and form pills more easily under friction. Selecting rayon over cotton enhances fabric durability and appearance by minimizing pilling in everyday wear and washing conditions.

Rayon Pilling vs Cotton Pilling Infographic

materialdif.com

materialdif.com