Rayon staple fiber consists of short, cut fibers spun into yarn, offering a soft texture ideal for breathable, comfortable fabrics in apparel and home textiles. Rayon filament yarn is produced from continuous filaments providing smoothness, strength, and a lustrous finish suitable for high-quality garments and luxury fabrics. The choice between staple fiber and filament yarn depends on the desired fabric characteristics like texture, durability, and appearance.

Table of Comparison

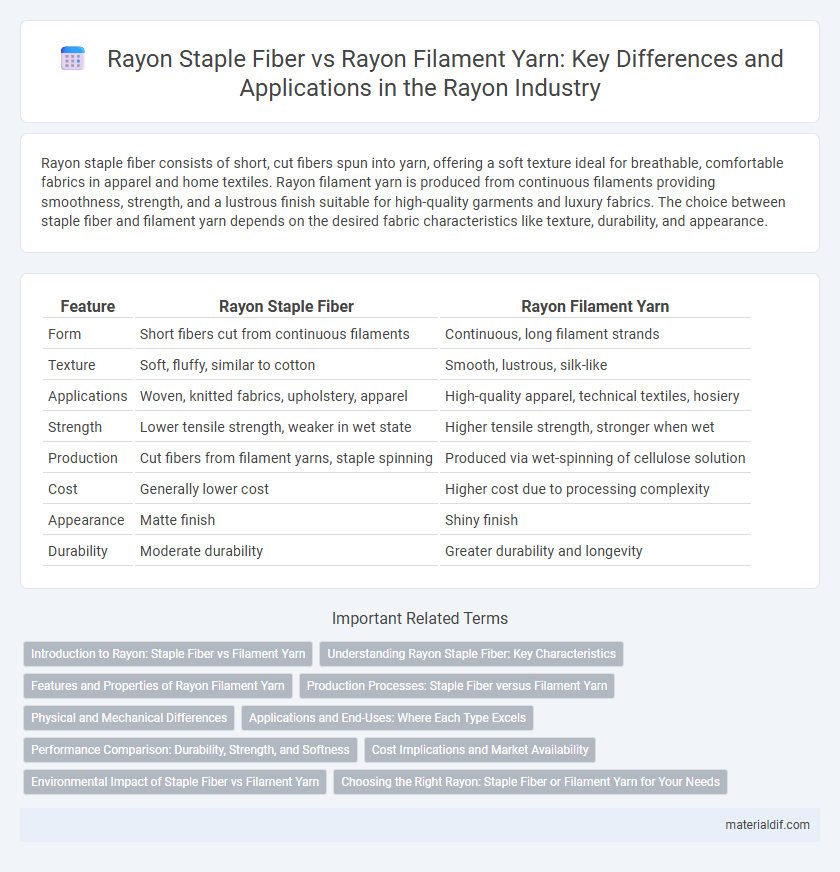

| Feature | Rayon Staple Fiber | Rayon Filament Yarn |

|---|---|---|

| Form | Short fibers cut from continuous filaments | Continuous, long filament strands |

| Texture | Soft, fluffy, similar to cotton | Smooth, lustrous, silk-like |

| Applications | Woven, knitted fabrics, upholstery, apparel | High-quality apparel, technical textiles, hosiery |

| Strength | Lower tensile strength, weaker in wet state | Higher tensile strength, stronger when wet |

| Production | Cut fibers from filament yarns, staple spinning | Produced via wet-spinning of cellulose solution |

| Cost | Generally lower cost | Higher cost due to processing complexity |

| Appearance | Matte finish | Shiny finish |

| Durability | Moderate durability | Greater durability and longevity |

Introduction to Rayon: Staple Fiber vs Filament Yarn

Rayon staple fiber consists of short fibers typically ranging from 38 to 51 millimeters in length, making it suitable for spinning into soft, breathable yarns for textiles requiring flexibility and comfort. Rayon filament yarn, produced as continuous filaments, offers a smooth, lustrous finish ideal for high-strength fabrics and applications demanding a silky texture. The distinct manufacturing processes and fiber lengths of staple fiber and filament yarn directly impact the mechanical properties and end-use performance of rayon-based products.

Understanding Rayon Staple Fiber: Key Characteristics

Rayon staple fiber consists of short, cut lengths of regenerated cellulose fibers, typically ranging from 1 to 5 centimeters, making it easier to blend with natural fibers like cotton and wool. This fiber type offers excellent breathability, high moisture absorbency, and a soft, silky texture, ideal for textiles requiring comfort and versatility. Unlike filament yarns, rayon staple fiber produces a more textured, matte finish fabric due to its shorter fiber length and structural properties.

Features and Properties of Rayon Filament Yarn

Rayon filament yarn consists of continuous filaments that provide a smoother texture, higher tensile strength, and better luster compared to staple fiber yarn, which is composed of shorter fiber lengths. The continuous nature of filament yarn enhances uniformity and reduces hairiness, resulting in superior drape and sheen ideal for high-quality textiles. Its excellent moisture absorption and breathability further contribute to comfort in garments made from rayon filament yarn.

Production Processes: Staple Fiber versus Filament Yarn

Rayon staple fiber is produced by cutting regenerated cellulose fibers into short lengths, which then undergo carding and spinning to form yarn, mimicking the production process of natural fibers like cotton. In contrast, rayon filament yarn is created by directly extruding continuous filaments from the cellulose solution, resulting in smoother, stronger yarns with uniform texture. The production of filament yarn involves fewer mechanical steps, leading to enhanced tensile strength and luster compared to the staple fiber, which offers versatility in textile applications due to its fiber length and blending capability.

Physical and Mechanical Differences

Rayon staple fiber consists of short fibers measuring a few centimeters, resulting in a softer texture and greater flexibility in weaving, while rayon filament yarn is made from continuous filaments that enhance strength and create smoother, more lustrous fabrics. The tensile strength of rayon filament yarn is significantly higher compared to staple fiber due to its unbroken fiber length, offering improved durability and resistance to wear. Staple fibers tend to have a higher moisture regain and lower tenacity, making them more prone to pilling and shrinkage, whereas filament yarns provide better dimensional stability and a more uniform appearance in textiles.

Applications and End-Uses: Where Each Type Excels

Rayon staple fiber is widely used in apparel such as shirts, dresses, and linings due to its soft texture and excellent breathability, making it ideal for comfortable, everyday wear. Rayon filament yarn finds its strength in applications requiring smoothness and luster, including high-end textiles, lingerie, and home furnishings like curtains and upholstery. The staple fiber's versatility suits mass-produced garments, while filament yarn excels in products demanding strength, sheen, and durability.

Performance Comparison: Durability, Strength, and Softness

Rayon filament yarn offers superior strength and durability compared to rayon staple fiber due to its continuous long filaments, which reduce weak points and enhance tensile properties. While rayon staple fiber provides excellent softness and breathability, staple fibers tend to have shorter fiber lengths that may decrease overall durability. The filament yarn's smooth surface also contributes to a silkier feel, making it ideal for applications requiring both strength and softness.

Cost Implications and Market Availability

Rayon staple fiber generally incurs lower production costs due to its shorter fiber length and simpler spinning process, making it more cost-effective for mass-market applications. Rayon filament yarn, produced via a continuous filament process, demands higher manufacturing precision, which increases its cost but also enhances fabric strength and luster. Market availability favors staple fiber for use in textiles like apparel and home furnishings, while filament yarn is preferred in high-end fabrics and technical textiles, influencing price and supply chain dynamics.

Environmental Impact of Staple Fiber vs Filament Yarn

Rayon staple fiber production generates more waste and consumes higher water and energy resources compared to filament yarn, due to fiber cutting and processing stages. Filament yarn manufacturing generally results in less environmental pollution because of continuous fiber extrusion, minimizing fiber scraps and chemical usage. Choosing filament yarn over staple fiber reduces pollutant emissions and conserves resources, making it a more sustainable option in rayon textile production.

Choosing the Right Rayon: Staple Fiber or Filament Yarn for Your Needs

Rayon staple fiber offers a soft texture and versatility ideal for blending in textiles, enhancing breathability and comfort in fabrics like denim and nonwovens. Rayon filament yarn provides smoothness and lustrous appearance, making it perfect for high-quality apparel and upholstery where sheen and durability are priorities. Selecting between staple fiber and filament yarn depends on the desired fabric characteristics, with staple fibers suited for versatility and filament yarns for strength and aesthetic appeal.

Rayon Staple Fiber vs Rayon Filament Yarn Infographic

materialdif.com

materialdif.com