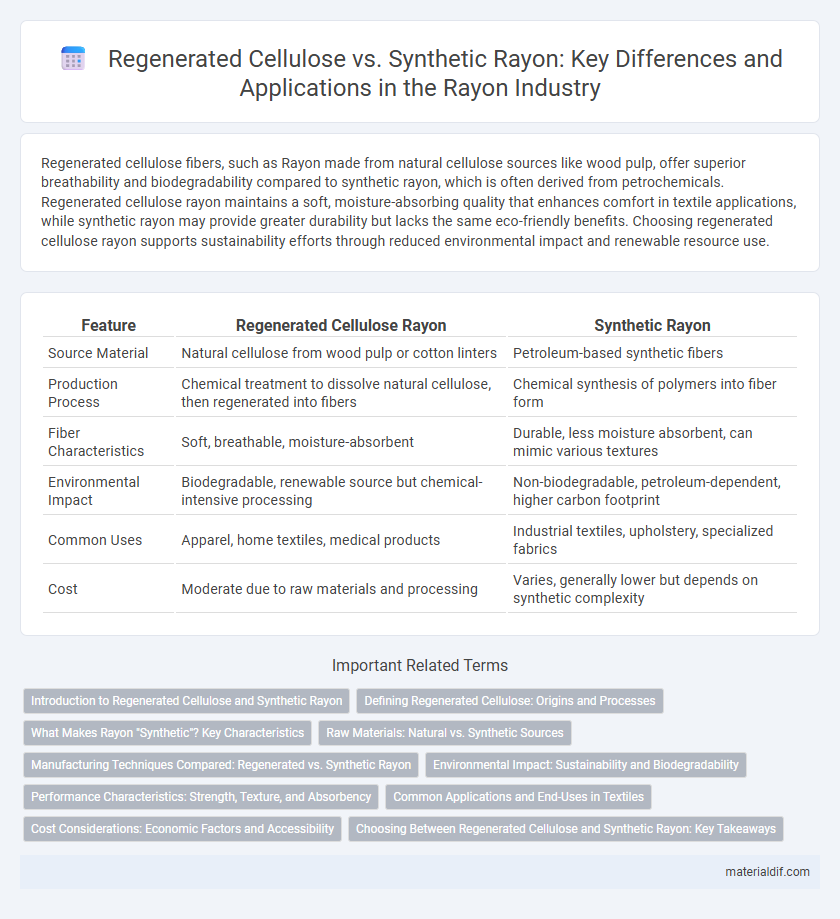

Regenerated cellulose fibers, such as Rayon made from natural cellulose sources like wood pulp, offer superior breathability and biodegradability compared to synthetic rayon, which is often derived from petrochemicals. Regenerated cellulose rayon maintains a soft, moisture-absorbing quality that enhances comfort in textile applications, while synthetic rayon may provide greater durability but lacks the same eco-friendly benefits. Choosing regenerated cellulose rayon supports sustainability efforts through reduced environmental impact and renewable resource use.

Table of Comparison

| Feature | Regenerated Cellulose Rayon | Synthetic Rayon |

|---|---|---|

| Source Material | Natural cellulose from wood pulp or cotton linters | Petroleum-based synthetic fibers |

| Production Process | Chemical treatment to dissolve natural cellulose, then regenerated into fibers | Chemical synthesis of polymers into fiber form |

| Fiber Characteristics | Soft, breathable, moisture-absorbent | Durable, less moisture absorbent, can mimic various textures |

| Environmental Impact | Biodegradable, renewable source but chemical-intensive processing | Non-biodegradable, petroleum-dependent, higher carbon footprint |

| Common Uses | Apparel, home textiles, medical products | Industrial textiles, upholstery, specialized fabrics |

| Cost | Moderate due to raw materials and processing | Varies, generally lower but depends on synthetic complexity |

Introduction to Regenerated Cellulose and Synthetic Rayon

Regenerated cellulose fibers, derived from natural cellulose sources such as wood pulp, undergo chemical processing to produce materials like viscose, lyocell, and modal, offering biodegradability and breathability. Synthetic rayon, often produced from modified cellulose but incorporating synthetic polymers, aims to enhance durability and moisture resistance while maintaining a textile feel. These fibers serve diverse applications in fashion, upholstery, and industrial textiles, balancing natural origin benefits with engineered performance.

Defining Regenerated Cellulose: Origins and Processes

Regenerated cellulose fibers, including viscose and lyocell, originate from natural cellulose extracted primarily from wood pulp, undergoing chemical processes to transform insoluble cellulose into a reusable fiber form. Unlike synthetic rayon derived from petrochemicals, regenerated cellulose retains biodegradable and breathable qualities due to its natural cellulose base. The production involves dissolving purified cellulose in solvents, followed by extrusion through spinnerets and regeneration into fibers, balancing sustainability with performance.

What Makes Rayon "Synthetic"? Key Characteristics

Rayon is considered synthetic because it undergoes extensive chemical processing to transform natural cellulose into fibers, differentiating it from purely natural fibers like cotton. Key characteristics of regenerated cellulose rayon include its soft texture, high breathability, and good moisture absorption, while synthetic rayon variants often incorporate polymer additives to enhance durability and wrinkle resistance. The synthetic aspect lies in the modification and reconstitution of cellulose into fiber form through industrial chemical treatments.

Raw Materials: Natural vs. Synthetic Sources

Regenerated cellulose rayon is derived from natural cellulose sources such as wood pulp and cotton linters, ensuring biodegradability and renewable raw materials. Synthetic rayon, on the other hand, relies on petrochemical-based polymers like petroleum and coal derivatives, making its source non-renewable and less environmentally friendly. The choice of raw materials significantly impacts the sustainability profile and environmental footprint of the final textile product.

Manufacturing Techniques Compared: Regenerated vs. Synthetic Rayon

Regenerated cellulose rayon is produced by chemically dissolving natural cellulose from wood pulp or cotton linters, followed by extrusion through spinnerets into fibers, using methods like the viscose, cuprammonium, or lyocell processes. Synthetic rayon, often derived from petrochemicals rather than natural cellulose, involves polymerization techniques that create fibers from entirely synthetic polymers, differing fundamentally from the regeneration of natural materials. The key manufacturing distinction lies in regenerated rayon's reliance on natural cellulose sources transformed chemically, whereas synthetic rayon is produced through synthetic polymer chemistry, impacting fiber properties and sustainability profiles.

Environmental Impact: Sustainability and Biodegradability

Regenerated cellulose fibers, derived from natural cellulose sources like wood pulp, exhibit higher biodegradability and lower environmental impact compared to synthetic rayon made from petrochemicals. The production of regenerated cellulose typically involves renewable raw materials and results in fibers that decompose more readily, reducing landfill waste and microplastic pollution. In contrast, synthetic rayon relies on non-renewable resources and involves energy-intensive processes, contributing to carbon emissions and persistent environmental pollutants.

Performance Characteristics: Strength, Texture, and Absorbency

Regenerated cellulose rayon exhibits superior moisture absorbency compared to synthetic rayon, making it ideal for breathable textiles and comfortable wear. Its natural fiber origin grants it a softer texture and excellent drape, whereas synthetic rayon variants often prioritize enhanced tensile strength but at the cost of reduced softness. In terms of durability, synthetic rayon fibers generally demonstrate higher tensile strength and abrasion resistance, offering longer-lasting performance in high-wear applications.

Common Applications and End-Uses in Textiles

Regenerated cellulose fibers, such as viscose and modal, are widely used in textiles for apparel, home furnishings, and nonwovens due to their softness, breathability, and moisture absorption. Synthetic rayon variants like lyocell offer enhanced strength, durability, and eco-friendly processing, making them common in activewear, denim blends, and technical fabrics. Both fiber types support versatile applications but are chosen based on performance needs and sustainability considerations in the textile industry.

Cost Considerations: Economic Factors and Accessibility

Regenerated cellulose, derived from natural sources like wood pulp, generally incurs higher production costs due to the intensive chemical processing and sustainability measures involved. Synthetic rayon, often made from petrochemical derivatives, tends to be more cost-effective, offering greater accessibility for mass-market textile manufacturing. Economic factors influencing cost differences include raw material availability, production scale, and environmental compliance expenses.

Choosing Between Regenerated Cellulose and Synthetic Rayon: Key Takeaways

Regenerated cellulose fibers, such as viscose and lyocell, offer superior breathability and biodegradability compared to synthetic rayon alternatives derived from petroleum-based polymers. The environmental impact of regenerated cellulose is typically lower, benefiting from renewable raw materials and reduced reliance on fossil fuels. Synthetic rayon, while often more durable and moisture-resistant, tends to have a higher ecological footprint and limited biodegradability, making regenerated cellulose a preferred choice for sustainable textile applications.

Regenerated cellulose vs Synthetic rayon Infographic

materialdif.com

materialdif.com