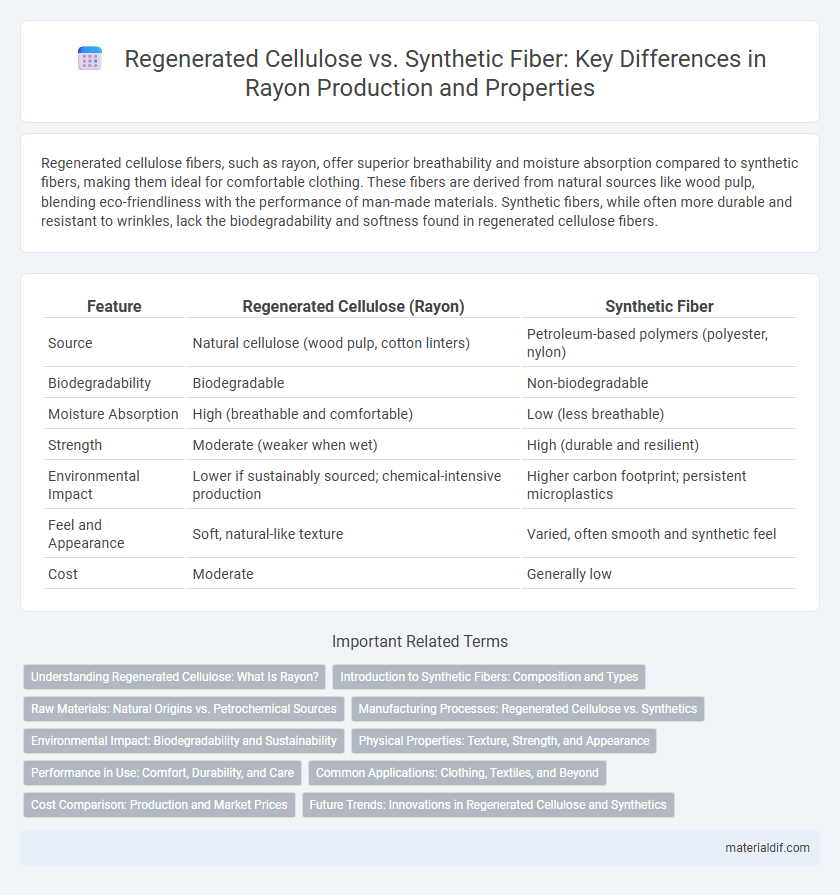

Regenerated cellulose fibers, such as rayon, offer superior breathability and moisture absorption compared to synthetic fibers, making them ideal for comfortable clothing. These fibers are derived from natural sources like wood pulp, blending eco-friendliness with the performance of man-made materials. Synthetic fibers, while often more durable and resistant to wrinkles, lack the biodegradability and softness found in regenerated cellulose fibers.

Table of Comparison

| Feature | Regenerated Cellulose (Rayon) | Synthetic Fiber |

|---|---|---|

| Source | Natural cellulose (wood pulp, cotton linters) | Petroleum-based polymers (polyester, nylon) |

| Biodegradability | Biodegradable | Non-biodegradable |

| Moisture Absorption | High (breathable and comfortable) | Low (less breathable) |

| Strength | Moderate (weaker when wet) | High (durable and resilient) |

| Environmental Impact | Lower if sustainably sourced; chemical-intensive production | Higher carbon footprint; persistent microplastics |

| Feel and Appearance | Soft, natural-like texture | Varied, often smooth and synthetic feel |

| Cost | Moderate | Generally low |

Understanding Regenerated Cellulose: What Is Rayon?

Rayon is a type of regenerated cellulose fiber made by chemically processing natural cellulose from wood pulp or cotton linters, offering a sustainable alternative to synthetic fibers derived from petrochemicals. Unlike synthetic fibers such as polyester or nylon, rayon retains the biodegradable properties of natural cellulose, making it an eco-friendlier textile option. Its versatility in texture and appearance allows it to mimic the look and feel of silk, cotton, or wool, which distinguishes rayon in the fashion and textile industries.

Introduction to Synthetic Fibers: Composition and Types

Synthetic fibers, primarily composed of petrochemicals such as polyethylene terephthalate (PET), nylon, and acrylic, are engineered through polymerization processes to create durable and versatile textile materials. These fibers are classified into various types including polyester, nylon, and spandex, each offering specific properties like elasticity, strength, and moisture resistance. Unlike regenerated cellulose fibers like rayon, synthetic fibers are entirely man-made, providing superior durability and resistance to biological degradation.

Raw Materials: Natural Origins vs. Petrochemical Sources

Regenerated cellulose fibers like rayon derive from natural origins, primarily wood pulp and other cellulose-rich plants, making them more sustainable compared to synthetic fibers that originate from petrochemical sources such as petroleum and natural gas. The extraction of cellulose involves fewer carbon emissions and relies on renewable resources, while synthetic fibers depend on finite fossil fuels with higher environmental footprints. Choosing regenerated cellulose over synthetic fibers supports eco-friendly material sourcing and reduces dependence on petrochemical-based raw materials.

Manufacturing Processes: Regenerated Cellulose vs. Synthetics

The manufacturing process of regenerated cellulose fibers like rayon involves dissolving natural cellulose from wood pulp or cotton linters into a viscous solution, followed by chemical treatment and extrusion through spinnerets to form fibers. In contrast, synthetic fibers such as polyester or nylon are produced through polymerization of petrochemicals, where monomers chemically bond to form long-chain polymers before being melted and extruded into filaments. Regenerated cellulose manufacturing emphasizes natural raw materials and complex chemical regeneration, while synthetic fiber production relies heavily on petroleum derivatives and polymer chemistry.

Environmental Impact: Biodegradability and Sustainability

Regenerated cellulose fibers like rayon are derived from natural cellulose sources, making them biodegradable and more environmentally sustainable compared to synthetic fibers such as polyester, which are petroleum-based and persist in ecosystems for decades. The production of rayon involves chemical processes that can impact the environment, but advancements in closed-loop manufacturing significantly reduce harmful emissions and waste. Overall, rayon offers a renewable alternative with a lower carbon footprint, promoting biodegradability and reducing microplastic pollution associated with synthetic fibers.

Physical Properties: Texture, Strength, and Appearance

Regenerated cellulose fibers, such as rayon, possess a smooth, silk-like texture that is highly absorbent and breathable, making them ideal for comfortable clothing. Compared to synthetic fibers like polyester, rayon generally exhibits lower tensile strength and reduced resistance to abrasion but offers superior softness and drape. Visually, rayon has a lustrous sheen that closely resembles natural fibers, providing an attractive appearance that synthetic fibers often lack.

Performance in Use: Comfort, Durability, and Care

Regenerated cellulose fibers, such as rayon, offer superior breathability and moisture absorption compared to synthetic fibers, enhancing comfort during wear. While synthetic fibers generally provide greater durability and resistance to abrasion, rayon delivers a softer hand feel but requires more delicate care to maintain its appearance and structural integrity. Proper laundering of rayon involves gentle washing and low drying temperatures to prevent shrinking and fiber damage, whereas synthetic fibers often tolerate more rigorous care conditions.

Common Applications: Clothing, Textiles, and Beyond

Regenerated cellulose fibers such as rayon, lyocell, and modal are extensively used in clothing and textiles due to their softness, breathability, and moisture-wicking properties, making them ideal for shirts, dresses, and activewear. Synthetic fibers like polyester, nylon, and acrylic dominate in durable and high-performance apparel, upholstery, and industrial textiles due to their strength, elasticity, and resistance to abrasion and chemicals. Beyond apparel, regenerated cellulose finds applications in medical textiles and hygiene products, while synthetic fibers are widely utilized in automotive fabrics, filtration, and geotextiles for their technical performance attributes.

Cost Comparison: Production and Market Prices

Regenerated cellulose fibers like rayon generally have lower production costs compared to synthetic fibers due to the use of renewable raw materials such as wood pulp and less energy-intensive processes. Market prices for rayon often remain competitive, reflecting its natural origin and biodegradability, whereas synthetic fibers like polyester typically command higher prices driven by petrochemical inputs and advanced manufacturing technologies. This cost advantage makes rayon a preferred choice in sustainable textile markets seeking balance between affordability and environmental impact.

Future Trends: Innovations in Regenerated Cellulose and Synthetics

Innovations in regenerated cellulose fibers are focusing on sustainability and advanced bioprocessing techniques to reduce environmental impact and enhance fiber performance. Synthetic fibers are evolving through the integration of bio-based polymers and smart textiles technology, improving durability and functionality. Future trends emphasize hybrid materials combining regenerated cellulose with synthetics to achieve superior comfort, strength, and eco-efficiency in textile applications.

Regenerated Cellulose vs Synthetic Fiber Infographic

materialdif.com

materialdif.com