Printing on rayon provides vibrant, detailed patterns that retain sharpness and allow for intricate designs, while dyeing offers a more uniform color wash that soaks deeply into the fibers. Printing techniques enable control over multiple colors and complex visuals without compromising fabric texture, whereas dyeing imparts a softer, more blended appearance but can sometimes affect the fabric's drape. Choosing between printing and dyeing on rayon depends on the desired aesthetic impact and fabric performance requirements.

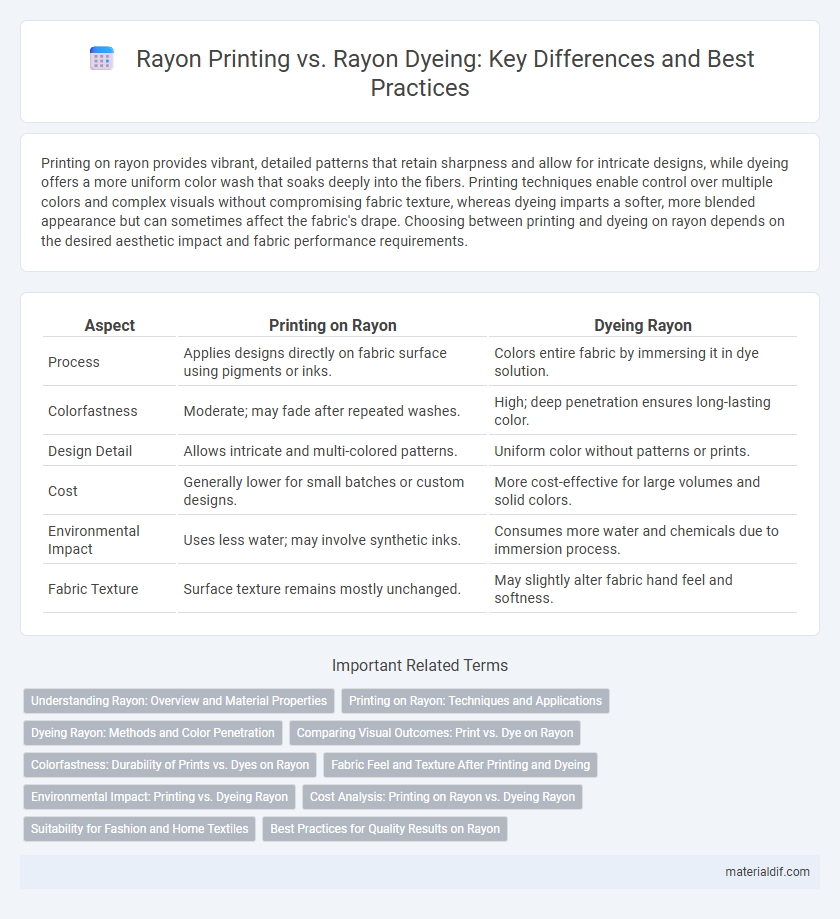

Table of Comparison

| Aspect | Printing on Rayon | Dyeing Rayon |

|---|---|---|

| Process | Applies designs directly on fabric surface using pigments or inks. | Colors entire fabric by immersing it in dye solution. |

| Colorfastness | Moderate; may fade after repeated washes. | High; deep penetration ensures long-lasting color. |

| Design Detail | Allows intricate and multi-colored patterns. | Uniform color without patterns or prints. |

| Cost | Generally lower for small batches or custom designs. | More cost-effective for large volumes and solid colors. |

| Environmental Impact | Uses less water; may involve synthetic inks. | Consumes more water and chemicals due to immersion process. |

| Fabric Texture | Surface texture remains mostly unchanged. | May slightly alter fabric hand feel and softness. |

Understanding Rayon: Overview and Material Properties

Rayon, a semi-synthetic fiber derived from cellulose, exhibits excellent absorbency and breathability, making it ideal for both printing and dyeing processes. Printing on rayon offers precise pattern details and vibrant colors due to its smooth surface, whereas dyeing penetrates the fibers, resulting in deep, lasting hues and enhanced fabric softness. Understanding rayon's hydrophilic nature and molecular structure is crucial for optimizing color application and achieving desired aesthetic and performance outcomes.

Printing on Rayon: Techniques and Applications

Printing on rayon employs advanced techniques such as screen printing, digital printing, and heat transfer to achieve vibrant, durable designs while preserving the fabric's softness and drape. These methods allow for intricate patterns and color variations that enhance rayon's natural sheen, making it ideal for fashion garments, home textiles, and accessories requiring high visual appeal. Modern printing technologies on rayon also optimize color fastness and reduce water consumption compared to traditional dyeing processes, improving sustainability and cost-effectiveness in textile production.

Dyeing Rayon: Methods and Color Penetration

Dyeing rayon involves immersing the fabric in dye baths, allowing for deep color penetration that enhances fabric vibrancy and durability. Common methods include vat dyeing, reactive dyeing, and disperse dyeing, each offering specific benefits for moisture absorption and color fastness. This process creates uniform coloration throughout the fiber, unlike printing, which applies pigment only on the surface.

Comparing Visual Outcomes: Print vs. Dye on Rayon

Printing on rayon produces sharp, detailed patterns with vibrant colors that sit on the fabric's surface, offering design precision and a wide color range. Dyeing rayon penetrates the fibers for a softer, more uniform color effect with subtle variations and excellent colorfastness. While prints allow for intricate graphics and vivid contrasts, dyed rayon showcases a smooth, consistent hue that enhances the fabric's natural drape and sheen.

Colorfastness: Durability of Prints vs. Dyes on Rayon

Printing on rayon offers vibrant, detailed designs but often suffers from reduced colorfastness compared to dyeing, as printed pigments tend to sit on the fabric surface and may fade or wash out faster. Dyeing rayon involves penetrating the fibers with color, resulting in more durable hues that retain brightness and resist fading through repeated laundering and exposure to sunlight. The colorfastness of dyed rayon generally surpasses printed variants, making dyeing the preferred method for long-lasting coloration on rayon textiles.

Fabric Feel and Texture After Printing and Dyeing

Printing on rayon preserves the fabric's original smooth and soft texture, as the ink sits on the surface without altering the fiber structure. Dyeing rayon, however, penetrates the fibers, resulting in a more uniform color but a slightly stiffer feel compared to printing. The choice between printing and dyeing rayon significantly impacts the fabric's hand feel and texture, with printing maintaining softness and dyeing offering enhanced colorfastness.

Environmental Impact: Printing vs. Dyeing Rayon

Printing on rayon uses less water and fewer chemicals compared to dyeing, reducing environmental pollution and wastewater treatment challenges. Dyeing rayon typically requires large volumes of water and energy, contributing to higher carbon emissions and potential toxic waste release. Opting for digital or water-based printing methods on rayon significantly decreases the ecological footprint by minimizing resource consumption and chemical discharge.

Cost Analysis: Printing on Rayon vs. Dyeing Rayon

Printing on rayon typically incurs lower costs than dyeing due to reduced water and energy consumption, making it a more economical choice for small to medium batches. Dyeing rayon involves extensive processing, requiring larger volumes of dyes and chemicals, which drives up both material and labor expenses. For large-scale production, dyeing might offer economies of scale, but printing provides greater flexibility and cost-efficiency in customized or limited runs.

Suitability for Fashion and Home Textiles

Printing on rayon offers vibrant, detailed patterns that enhance its natural sheen, making it highly suitable for fashion items like dresses and blouses where intricate designs are desired. Dyeing rayon provides uniform color saturation ideal for home textiles such as curtains and upholstery, where consistent hues are preferred over complex patterns. The choice between printing and dyeing rayon hinges on the end use, balancing aesthetic appeal with functional durability in both fashion and interior applications.

Best Practices for Quality Results on Rayon

Printing on rayon requires precise control of ink viscosity and curing temperature to prevent fabric damage and ensure vibrant, long-lasting designs. Dyeing rayon involves thorough fiber preparation and consistent temperature regulation during the vat dyeing process to achieve deep, uniform coloration and maintain fabric strength. Utilizing reactive dyes for both methods optimizes colorfastness and enhances the overall quality and durability of the finished rayon products.

Printing on Rayon vs Dyeing Rayon Infographic

materialdif.com

materialdif.com