Rayon finishing involves a smoother, glossier surface achieved through heat-setting and calendaring, enhancing its softness and drape compared to cotton finishing. Cotton finishing emphasizes durability and breathability, often involving treatments like mercerization to increase strength and absorbency. While rayon finishing prioritizes aesthetic appeal and fluidity, cotton finishing focuses on longevity and comfort in everyday wear.

Table of Comparison

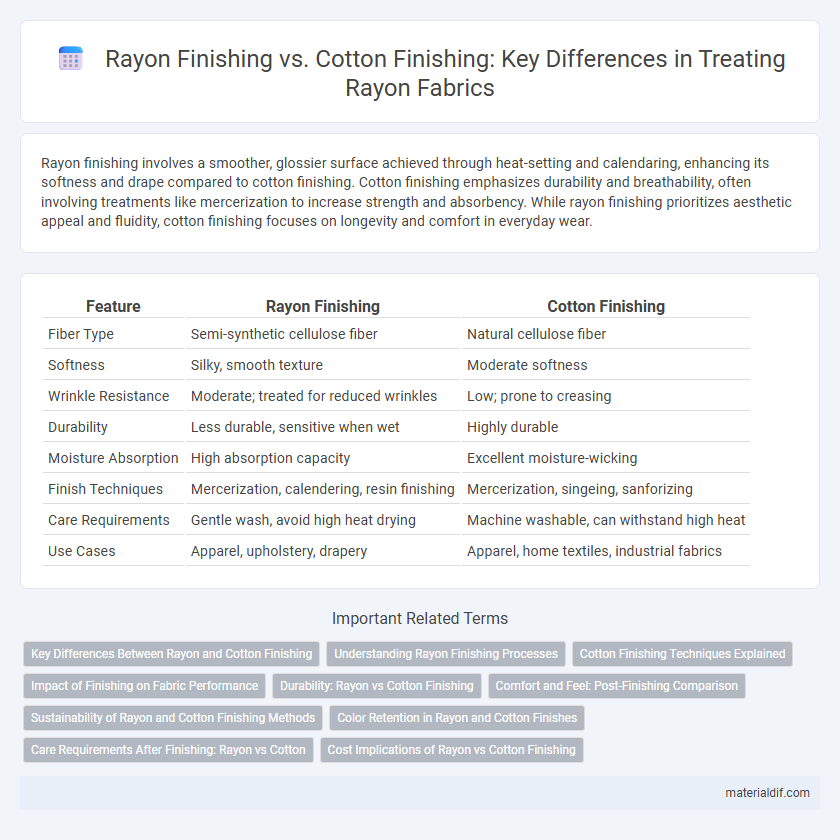

| Feature | Rayon Finishing | Cotton Finishing |

|---|---|---|

| Fiber Type | Semi-synthetic cellulose fiber | Natural cellulose fiber |

| Softness | Silky, smooth texture | Moderate softness |

| Wrinkle Resistance | Moderate; treated for reduced wrinkles | Low; prone to creasing |

| Durability | Less durable, sensitive when wet | Highly durable |

| Moisture Absorption | High absorption capacity | Excellent moisture-wicking |

| Finish Techniques | Mercerization, calendering, resin finishing | Mercerization, singeing, sanforizing |

| Care Requirements | Gentle wash, avoid high heat drying | Machine washable, can withstand high heat |

| Use Cases | Apparel, upholstery, drapery | Apparel, home textiles, industrial fabrics |

Key Differences Between Rayon and Cotton Finishing

Rayon finishing involves chemical treatments to enhance fabric softness, luster, and drape, whereas cotton finishing primarily relies on mechanical processes to improve texture and durability. Rayon finishes often include mercerization and washing to achieve a silky feel, while cotton finishing emphasizes crease resistance and color retention through calendaring and heat setting. The key difference lies in rayon's semi-synthetic nature requiring specialized chemical finishing, contrasting with cotton's natural fibers suited for traditional mechanical finishing methods.

Understanding Rayon Finishing Processes

Rayon finishing involves specialized processes such as mercerization and heat setting to enhance luster, strength, and dimensional stability, differentiating it significantly from cotton finishing. Cotton finishing primarily focuses on softening and improving breathability, while rayon finishing requires additional chemical treatments to maintain its delicate fiber structure and improve durability. Understanding these distinct finishing techniques is essential for optimizing the performance and aesthetic qualities of rayon fabrics in comparison to cotton.

Cotton Finishing Techniques Explained

Cotton finishing techniques involve processes such as bleaching, mercerizing, and calendaring to enhance fabric strength, luster, and softness, distinguishing it from rayon finishing which often prioritizes smoothness and drape. Mercerizing cotton elevates fiber tensile strength and increases dye affinity, resulting in vibrant, long-lasting colors, a treatment less common in rayon finishing. Calendaring imparts a polished appearance and reduces fabric thickness in cotton, optimizing it for diverse textile applications.

Impact of Finishing on Fabric Performance

Rayon finishing enhances fabric softness and drape but often requires specialized treatments to improve durability and moisture resistance, unlike cotton finishing which naturally promotes breathability and strength due to its fiber structure. The chemical processes in rayon finishing can influence colorfastness and reduce shrinkage, whereas cotton finishing focuses on maintaining fiber resilience and wrinkle resistance through mechanical and enzymatic methods. Understanding these finishing impacts is crucial for optimizing fabric performance based on end-use requirements such as comfort, appearance, and longevity.

Durability: Rayon vs Cotton Finishing

Rayon finishing typically results in fabrics that are softer and more lustrous but less durable compared to cotton finishing, which enhances cotton's natural strength and resilience. Cotton finishing processes improve fiber toughness and resistance to wear, making cotton garments more long-lasting under frequent use. In contrast, rayon fibers may weaken with repeated laundering and abrasion due to their semi-synthetic nature and lower tensile strength.

Comfort and Feel: Post-Finishing Comparison

Rayon finishing typically yields a softer, silkier feel compared to cotton finishing, which often results in a more textured, crisp hand. The moisture-wicking properties of rayon enhance comfort by allowing better breathability and a cooler touch, while cotton finishing offers durability with a slightly heavier feel. Post-finishing treatments on rayon enhance drape and smoothness, whereas cotton finishing emphasizes resilience and a natural, matte appearance.

Sustainability of Rayon and Cotton Finishing Methods

Rayon finishing techniques often involve chemical processes that can impact environmental sustainability due to the use of toxic solvents like carbon disulfide, whereas cotton finishing generally relies on mechanical and natural treatments with lower chemical intensity. Sustainable advancements in rayon finishing focus on closed-loop systems and enzymatic treatments that reduce emissions and water usage, making rayon more eco-friendly compared to traditional methods. Cotton finishing benefits from organic farming practices and water-efficient dyeing technologies, but rayon's evolving green techniques are closing the sustainability gap between the two fibers.

Color Retention in Rayon and Cotton Finishes

Rayon finishing involves specialized chemical treatments that enhance color retention, preventing fading and maintaining vibrancy over time. Unlike cotton finishing, which often requires additional dye fixation processes due to natural fiber variability, rayon's regenerated cellulose fibers absorb dyes more uniformly, resulting in more consistent and long-lasting color. This superior color retention in rayon finishes makes it preferable for garments demanding durability and vivid hues.

Care Requirements After Finishing: Rayon vs Cotton

Rayon finishing typically requires more delicate care than cotton due to its sensitivity to heat and moisture, necessitating low-temperature ironing and gentle washing to prevent fabric damage. Cotton finishing allows for higher heat tolerance, making it suitable for machine washing and high-temperature ironing without significantly compromising fabric integrity. Proper care after finishing ensures rayon maintains its softness and drape, while cotton retains its durability and structure over time.

Cost Implications of Rayon vs Cotton Finishing

Rayon finishing typically incurs higher costs than cotton finishing due to its delicate fiber structure requiring specialized treatments and machinery to avoid damage. Cotton finishing benefits from established, cost-efficient processes that leverage the natural durability of cotton fibers, reducing overall production expenses. The increased labor and chemical usage necessary for rayon finishing contribute significantly to its elevated cost implications in textile manufacturing.

Rayon Finishing vs Cotton Finishing Infographic

materialdif.com

materialdif.com