Rayon filament yarn offers superior smoothness and strength due to its continuous fiber length compared to staple fiber yarn, which consists of shorter fibers spun together. Filament yarn provides a lustrous, uniform appearance ideal for high-quality textiles, while staple fiber yarn yields a softer, more textured fabric with higher absorbency. Choosing between rayon filament and staple fiber yarn depends on the desired fabric characteristics and end-use applications.

Table of Comparison

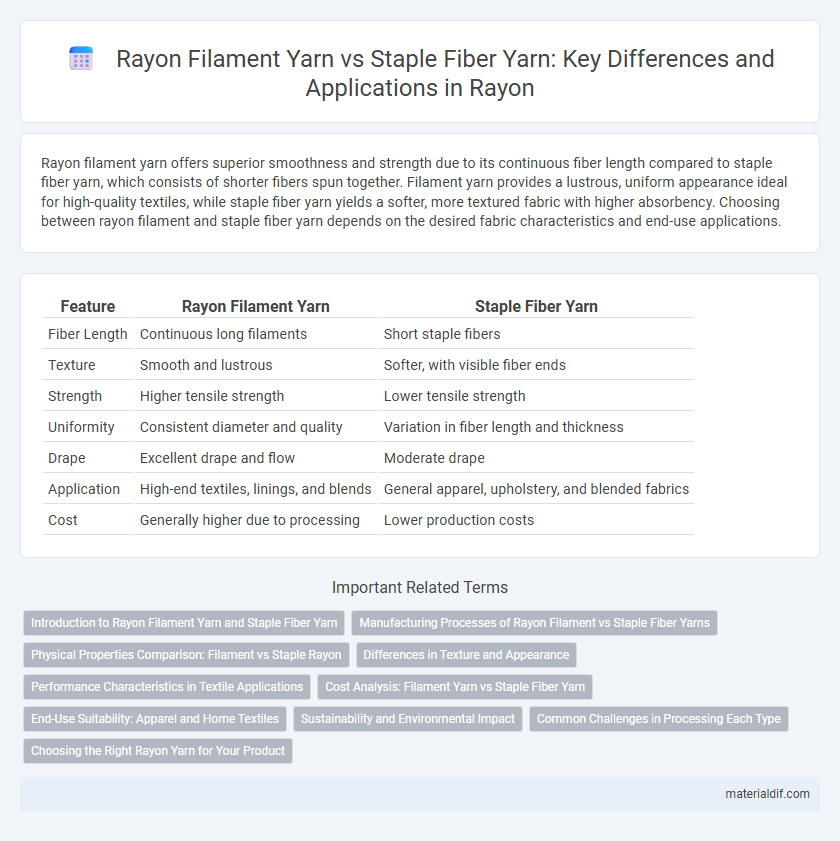

| Feature | Rayon Filament Yarn | Staple Fiber Yarn |

|---|---|---|

| Fiber Length | Continuous long filaments | Short staple fibers |

| Texture | Smooth and lustrous | Softer, with visible fiber ends |

| Strength | Higher tensile strength | Lower tensile strength |

| Uniformity | Consistent diameter and quality | Variation in fiber length and thickness |

| Drape | Excellent drape and flow | Moderate drape |

| Application | High-end textiles, linings, and blends | General apparel, upholstery, and blended fabrics |

| Cost | Generally higher due to processing | Lower production costs |

Introduction to Rayon Filament Yarn and Staple Fiber Yarn

Rayon filament yarn is composed of continuous filaments that produce a smooth, lustrous texture ideal for high-quality textiles, while staple fiber yarn consists of short fibers spun together to create a softer, more textured fabric. Filament yarn enhances strength and durability in rayon textiles, making it suitable for fine garments and upholstery. Staple fiber yarn offers superior breathability and absorbency, commonly used in casual wear and home textiles.

Manufacturing Processes of Rayon Filament vs Staple Fiber Yarns

Rayon filament yarn is produced through a continuous spinning process where regenerated cellulose is extruded into long, smooth filaments, resulting in a high-strength, uniform yarn ideal for fine textiles. Staple fiber yarn manufacturing involves cutting the regenerated cellulose into short fibers, followed by processes like carding and spinning to align and twist the fibers into yarn, yielding a softer, bulkier texture suitable for heavier fabrics. The filament yarn process emphasizes precision and control to maintain filament integrity, while staple fiber yarn production relies on blending and mechanical manipulation to enhance fiber cohesion and fabric versatility.

Physical Properties Comparison: Filament vs Staple Rayon

Rayon filament yarn exhibits superior tensile strength and smoother texture compared to staple fiber yarn due to its continuous fiber length, which enhances durability and reduces pilling. Staple rayon yarn, composed of shorter fibers, offers greater breathability and softness, making it ideal for lightweight and comfortable textiles. The filament form maintains consistent diameter and luster, while staple fibers provide increased elasticity and absorbency, influencing end-use performance.

Differences in Texture and Appearance

Rayon filament yarn offers a smooth, lustrous texture and a consistent appearance due to its continuous fibers, which enhance fabric sheen and uniformity. Staple fiber yarn, composed of short, cut fibers, results in a softer, fuzzier texture with a more matte and irregular surface. These differences affect fabric drape, durability, and visual aesthetics, making filament yarns ideal for luxurious textiles while staple yarns suit cozy, casual fabrics.

Performance Characteristics in Textile Applications

Rayon filament yarn offers superior strength, smoothness, and luster compared to staple fiber yarn, making it ideal for high-quality textile applications requiring durability and sheen. Staple fiber yarn, composed of shorter fibers, provides better breathability and softness, enhancing comfort in clothing and home textiles. Performance in dye uptake favors staple fiber yarn due to its higher surface area, while filament yarns excel in uniformity and resistance to pilling, crucial for premium fabric finishes.

Cost Analysis: Filament Yarn vs Staple Fiber Yarn

Rayon filament yarn generally incurs higher production costs due to the continuous fiber spinning process and the requirement for advanced machinery, while staple fiber yarn involves shorter fibers that are cheaper to produce but require additional processing to spin into yarn. Cost analysis reveals that filament yarn offers superior strength and uniformity, potentially reducing waste and improving product durability, offsetting its higher initial investment. Staple fiber yarn remains cost-effective for bulk production where price sensitivity dominates, but filament yarn's technological benefits support premium applications with greater performance demands.

End-Use Suitability: Apparel and Home Textiles

Rayon filament yarn offers a smooth, lustrous texture ideal for high-end apparel such as blouses and evening wear, enhancing fabric drape and sheen. Staple fiber yarn, composed of shorter fibers, provides greater warmth and durability, making it suitable for home textiles like upholstery and curtains. The choice between filament and staple yarn depends on desired fabric characteristics, with filament yarn excelling in softness and appearance for clothing, while staple yarn suits heavier, more resilient household fabrics.

Sustainability and Environmental Impact

Rayon filament yarn demonstrates greater sustainability by producing fewer microfibers during washing compared to staple fiber yarn, which sheds more fibers leading to increased water pollution. The manufacturing process of filament yarn is more energy-efficient and generates less waste, reducing the overall carbon footprint relative to staple fiber yarn. Filament yarn's longer fibers enhance fabric durability, encouraging extended garment life and minimizing textile waste in landfills.

Common Challenges in Processing Each Type

Rayon filament yarn often faces challenges such as filament breakage and uneven tension during spinning, which can affect fabric uniformity and strength. Staple fiber yarn processing struggles with fiber alignment and short fiber entanglement, leading to issues like uneven yarn thickness and increased hairiness. Both types require careful control of moisture content and spinning parameters to optimize durability and fabric appearance.

Choosing the Right Rayon Yarn for Your Product

Rayon filament yarn offers smoothness and strength, making it ideal for high-quality, lustrous fabrics used in apparel and home textiles. Staple fiber yarn provides a softer, more textured feel, better suited for casual wear and cozy textiles requiring breathability. Evaluating product requirements such as durability, texture, and appearance helps determine whether filament or staple rayon yarn best aligns with your design and performance goals.

Rayon filament yarn vs Staple fiber yarn Infographic

materialdif.com

materialdif.com