Lyocell offers superior environmental benefits compared to traditional rayon, as it is produced using a closed-loop process that recycles almost all solvents, minimizing harmful emissions. Rayon, derived from cellulose fibers, often involves more chemically intensive production methods that contribute to environmental pollution. Lyocell fibers are also stronger, more absorbent, and more breathable than rayon, making them ideal for sustainable and comfortable textile applications.

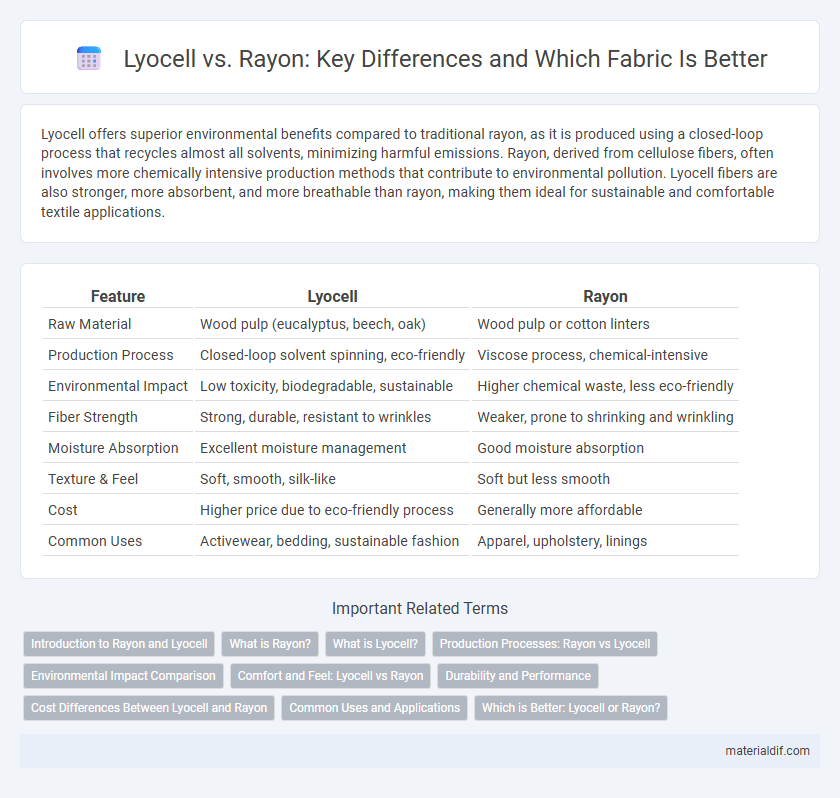

Table of Comparison

| Feature | Lyocell | Rayon |

|---|---|---|

| Raw Material | Wood pulp (eucalyptus, beech, oak) | Wood pulp or cotton linters |

| Production Process | Closed-loop solvent spinning, eco-friendly | Viscose process, chemical-intensive |

| Environmental Impact | Low toxicity, biodegradable, sustainable | Higher chemical waste, less eco-friendly |

| Fiber Strength | Strong, durable, resistant to wrinkles | Weaker, prone to shrinking and wrinkling |

| Moisture Absorption | Excellent moisture management | Good moisture absorption |

| Texture & Feel | Soft, smooth, silk-like | Soft but less smooth |

| Cost | Higher price due to eco-friendly process | Generally more affordable |

| Common Uses | Activewear, bedding, sustainable fashion | Apparel, upholstery, linings |

Introduction to Rayon and Lyocell

Rayon, a semi-synthetic fiber derived from cellulose, offers breathability and softness similar to natural fibers, making it popular in textiles. Lyocell, a type of rayon, is produced through a more sustainable, closed-loop process that reduces environmental impact and enhances fiber strength and moisture absorption. Both fibers are versatile and widely used in apparel, but Lyocell is favored for eco-conscious consumers seeking biodegradable and hypoallergenic fabric options.

What is Rayon?

Rayon is a semi-synthetic fiber made from regenerated cellulose derived primarily from wood pulp, offering a versatile alternative to natural fibers like cotton and silk. Unlike Lyocell, which uses a closed-loop solvent process, traditional rayon production involves chemical treatments with carbon disulfide and sodium hydroxide, impacting environmental sustainability. Rayon's softness, breathability, and ability to absorb dyes make it widely used in textiles for clothing, upholstery, and industrial products.

What is Lyocell?

Lyocell is a type of cellulose fiber made from sustainably sourced wood pulp, primarily eucalyptus, beech, or spruce trees, produced through a closed-loop solvent spinning process that minimizes environmental impact. Unlike traditional rayon, which uses toxic chemicals like carbon disulfide, Lyocell's eco-friendly production ensures lower emissions and water pollution. Its biodegradable nature, combined with high moisture absorption and breathability, makes Lyocell a preferred choice for sustainable textiles and performance fabrics.

Production Processes: Rayon vs Lyocell

Rayon production involves chemically steeping cellulose fibers in alkali and carbon disulfide to create viscose, which is then regenerated into fibers, whereas Lyocell utilizes a closed-loop process dissolving cellulose in non-toxic N-methylmorpholine N-oxide solvent, making it more environmentally sustainable. The viscose method in Rayon leads to higher chemical waste, while Lyocell's solvent is almost entirely recycled, reducing environmental impact. This key difference in production processes positions Lyocell as a more eco-friendly alternative to conventional Rayon.

Environmental Impact Comparison

Lyocell and rayon differ significantly in environmental impact, with lyocell being more eco-friendly due to its closed-loop production process that recycles over 99% of solvents, reducing chemical waste and water pollution. Rayon production involves toxic chemicals like carbon disulfide, contributing to air and water contamination, whereas lyocell uses non-toxic amine oxide, making it safer for workers and ecosystems. The biodegradability of both fibers is similar, but lyocell's sustainable raw material sourcing from sustainably managed eucalyptus forests further enhances its environmental credentials.

Comfort and Feel: Lyocell vs Rayon

Lyocell offers superior comfort compared to traditional rayon due to its smoother, softer texture and excellent moisture-wicking properties, making it ideal for sensitive skin. Rayon tends to be less breathable and can feel heavier and less smooth, which might cause discomfort in hot or humid conditions. The eco-friendly production process of lyocell also results in a fabric with enhanced durability and a silky, cool feel that rayon fabrics typically lack.

Durability and Performance

Lyocell fibers exhibit superior durability compared to traditional rayon due to their higher tensile strength and resistance to wear and tear. Performance-wise, lyocell offers enhanced moisture-wicking properties and breathability, making it more suitable for activewear and high-performance textiles. Rayon tends to be less durable and more prone to shrinking and wrinkling, limiting its use in long-lasting apparel.

Cost Differences Between Lyocell and Rayon

Lyocell typically costs more than rayon due to its eco-friendly closed-loop production process, which uses non-toxic solvents and recycles water and chemicals, increasing manufacturing expenses. Rayon, produced through a more traditional and less sustainable viscose method, benefits from lower raw material and process costs, making it a cheaper option for textile manufacturers. The price disparity influences market preference, with lyocell favored for premium, sustainable fabrics, while rayon remains popular for budget-conscious applications.

Common Uses and Applications

Lyocell and rayon are widely used in the textile industry for apparel, home textiles, and industrial products due to their soft texture and moisture-wicking properties. Lyocell is favored in activewear and eco-friendly fashion for its sustainable production process and durability, while rayon is commonly found in dresses, linings, and upholstery because of its smooth feel and affordability. Both fibers serve important roles in producing comfortable, breathable fabrics for everyday clothing and specialty uses.

Which is Better: Lyocell or Rayon?

Lyocell and Rayon are both semi-synthetic fibers derived from cellulose, but Lyocell is considered better due to its environmentally friendly closed-loop production process that recycles solvents and reduces waste. Lyocell offers superior moisture-wicking properties, breathability, and durability compared to traditional Rayon, making it ideal for activewear and sustainable fashion. Its biodegradable nature and less harmful chemical usage provide a more eco-conscious alternative without compromising fabric softness or comfort.

Lyocell vs Rayon Infographic

materialdif.com

materialdif.com