Cross-linked rayon offers enhanced durability and dimensional stability compared to non-cross-linked rayon, making it ideal for products requiring long-lasting performance. The cross-linking process creates strong chemical bonds between polymer chains, improving resistance to shrinkage and moisture absorption. Non-cross-linked rayon, while softer and more absorbent, tends to lose shape and integrity faster under stress or repeated washing.

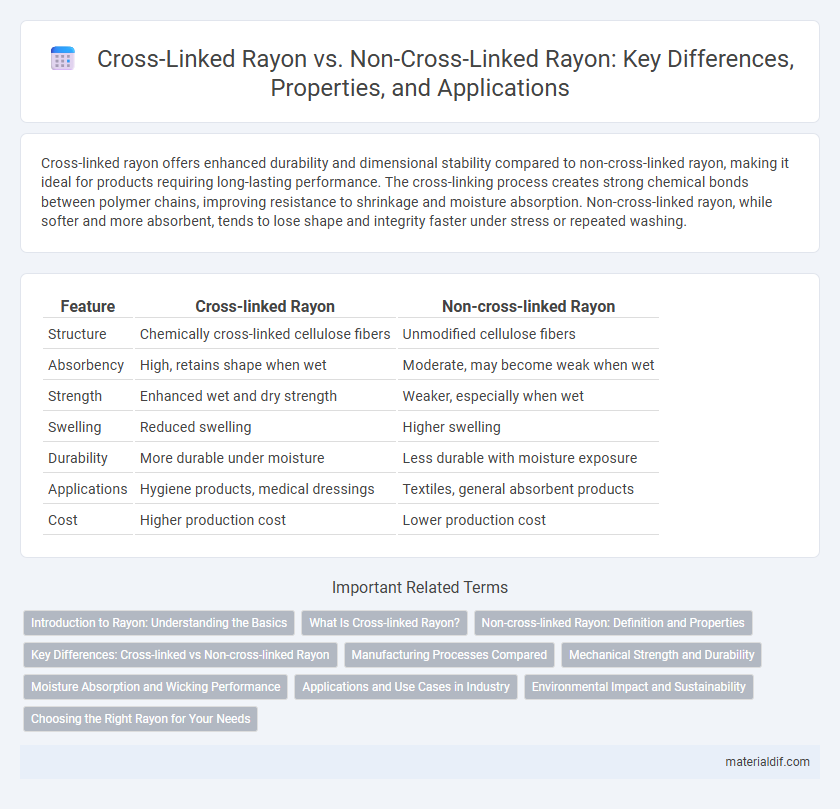

Table of Comparison

| Feature | Cross-linked Rayon | Non-cross-linked Rayon |

|---|---|---|

| Structure | Chemically cross-linked cellulose fibers | Unmodified cellulose fibers |

| Absorbency | High, retains shape when wet | Moderate, may become weak when wet |

| Strength | Enhanced wet and dry strength | Weaker, especially when wet |

| Swelling | Reduced swelling | Higher swelling |

| Durability | More durable under moisture | Less durable with moisture exposure |

| Applications | Hygiene products, medical dressings | Textiles, general absorbent products |

| Cost | Higher production cost | Lower production cost |

Introduction to Rayon: Understanding the Basics

Rayon, a semi-synthetic fiber derived from cellulose, exhibits distinct properties depending on its cross-linking status, with cross-linked rayon offering enhanced strength, dimensional stability, and resistance to moisture compared to non-cross-linked variants. The cross-linking process modifies the molecular structure, creating chemical bonds that improve durability and reduce fiber swelling in humid conditions. Non-cross-linked rayon remains more absorbent and softer but is prone to shrinking and losing shape, making the choice between types crucial for applications demanding specific performance characteristics.

What Is Cross-linked Rayon?

Cross-linked rayon is a type of cellulose fiber chemically treated to form covalent bonds between polymer chains, enhancing its strength, stability, and moisture absorption compared to non-cross-linked rayon. This modification improves dimensional stability and reduces shrinkage, making cross-linked rayon ideal for applications requiring durability and resistance to deformation. In contrast, non-cross-linked rayon lacks these interchain bonds, resulting in fibers that are more prone to swelling, weaker tensile properties, and greater susceptibility to water absorption changes.

Non-cross-linked Rayon: Definition and Properties

Non-cross-linked rayon is a type of regenerated cellulose fiber that lacks chemical cross-linking between polymer chains, resulting in higher water absorbency and increased softness. This fiber exhibits lower dimensional stability and reduced resistance to shrinking compared to cross-linked rayon, making it more prone to deformation when wet. Its natural cellulose structure provides excellent breathability and moisture management, ideal for applications requiring comfort and softness.

Key Differences: Cross-linked vs Non-cross-linked Rayon

Cross-linked rayon fibers undergo a chemical treatment that creates covalent bonds between cellulose chains, enhancing moisture resistance, dimensional stability, and durability compared to non-cross-linked rayon. Non-cross-linked rayon retains higher absorbency and softness but tends to swell, weaken when wet, and exhibit reduced shape retention. Cross-linked rayon is preferred for applications requiring water resistance and mechanical strength, while non-cross-linked rayon suits uses prioritizing comfort and breathability.

Manufacturing Processes Compared

Cross-linked rayon manufacturing involves chemically treating cellulose fibers with cross-linking agents such as formaldehyde or glutaraldehyde, creating covalent bonds between polymer chains that enhance fiber strength, dimensional stability, and moisture resistance. In contrast, non-cross-linked rayon is produced through a standard viscose process without additional chemical cross-linking, resulting in fibers with higher absorbency but lower mechanical durability and shrink resistance. The cross-linking step requires precise control of reaction conditions and post-treatment drying stages, increasing manufacturing complexity and cost compared to conventional non-cross-linked rayon production.

Mechanical Strength and Durability

Cross-linked rayon exhibits superior mechanical strength and enhanced durability compared to non-cross-linked rayon due to its chemically bonded polymer chains that resist deformation and wear. The cross-linking process improves fiber stability, resulting in increased tensile strength and resistance to water and chemical damage. Non-cross-linked rayon tends to have lower mechanical resilience, making it more susceptible to fiber breakdown and reduced lifespan under stress.

Moisture Absorption and Wicking Performance

Cross-linked rayon exhibits superior moisture absorption and enhanced wicking performance compared to non-cross-linked rayon due to its chemically modified polymer network that increases hydrophilicity and porosity. The cross-linking process creates a stable three-dimensional structure, facilitating faster moisture transport away from the skin and promoting a drier, more comfortable fabric feel. Non-cross-linked rayon, while absorbent, tends to retain moisture longer, resulting in slower drying times and reduced overall comfort in active or humid conditions.

Applications and Use Cases in Industry

Cross-linked rayon exhibits enhanced moisture retention and dimensional stability, making it ideal for high-performance hygiene products such as surgical dressings and advanced wound care. Non-cross-linked rayon offers superior absorbency and softness, commonly utilized in disposable wipes, household cleaning cloths, and personal hygiene items like tampons. Industrial applications leverage cross-linked rayon for filtration media and medical textiles where durability and fluid control are critical, while non-cross-linked variants serve in oil spill cleanup and cosmetic product formulation due to their natural absorbent properties.

Environmental Impact and Sustainability

Cross-linked rayon exhibits enhanced durability and biodegradability compared to non-cross-linked rayon, reducing environmental waste during decomposition. The cross-linking process utilizes fewer harmful chemicals and lowers water consumption, promoting sustainable manufacturing practices. Non-cross-linked rayon often requires intensive chemical treatments, resulting in higher pollution and resource depletion, making cross-linked rayon a more eco-friendly alternative.

Choosing the Right Rayon for Your Needs

Cross-linked rayon offers enhanced durability and resistance to deformation, making it ideal for applications requiring high tensile strength and longevity, such as industrial textiles and medical products. Non-cross-linked rayon provides superior softness and absorbency, preferred for clothing and disposable hygiene products where comfort and moisture management are critical. Selecting the right rayon depends on balancing performance requirements with end-use demands, ensuring optimal fabric functionality and cost-effectiveness.

Cross-linked Rayon vs Non-cross-linked Rayon Infographic

materialdif.com

materialdif.com