Acetate and rayon are both semi-synthetic fibers derived from cellulose, but acetate is produced using acetic acid while rayon undergoes a chemical process involving carbon disulfide. Acetate offers a silk-like appearance and is more resistant to shrinking and stretching, whereas rayon boasts higher absorbency and breathability, making it ideal for lightweight garments. Choosing between acetate and rayon depends on the desired fabric characteristics such as durability, comfort, and care requirements.

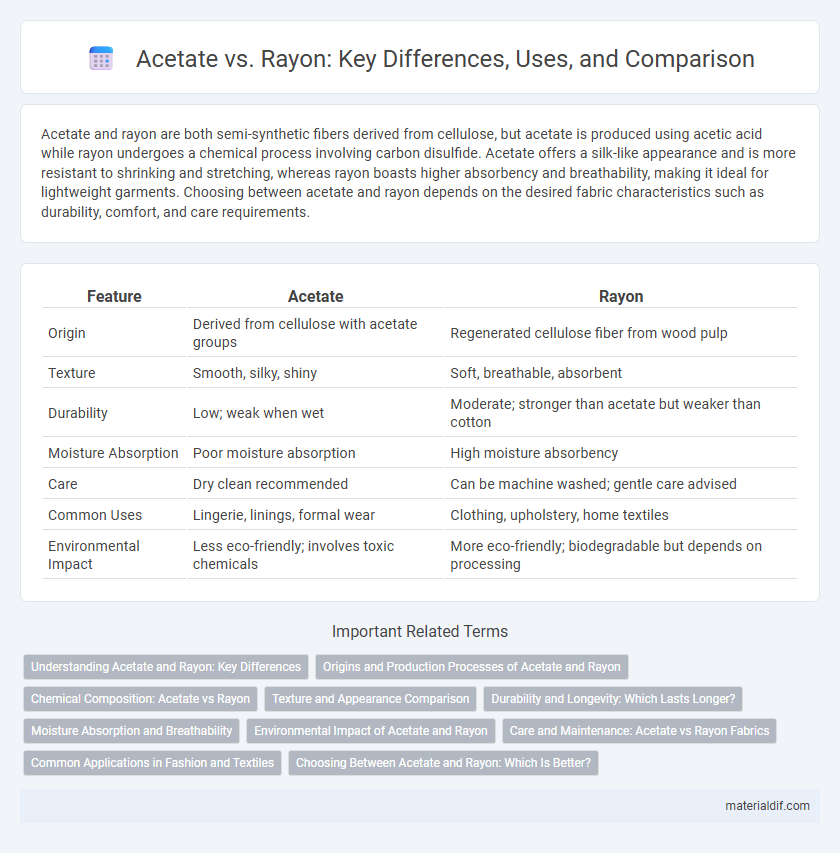

Table of Comparison

| Feature | Acetate | Rayon |

|---|---|---|

| Origin | Derived from cellulose with acetate groups | Regenerated cellulose fiber from wood pulp |

| Texture | Smooth, silky, shiny | Soft, breathable, absorbent |

| Durability | Low; weak when wet | Moderate; stronger than acetate but weaker than cotton |

| Moisture Absorption | Poor moisture absorption | High moisture absorbency |

| Care | Dry clean recommended | Can be machine washed; gentle care advised |

| Common Uses | Lingerie, linings, formal wear | Clothing, upholstery, home textiles |

| Environmental Impact | Less eco-friendly; involves toxic chemicals | More eco-friendly; biodegradable but depends on processing |

Understanding Acetate and Rayon: Key Differences

Acetate fibers are derived from cellulose acetate, offering a silky appearance and excellent drape, while rayon is produced from regenerated cellulose fibers, known for its breathability and versatility. Acetate tends to have lower moisture absorption and dries quickly, making it suitable for formal wear and linings, whereas rayon's higher moisture retention provides comfort in casual and summer clothing. Both fibers share a cellulose base but differ significantly in chemical processing and performance characteristics, influencing their applications in textiles.

Origins and Production Processes of Acetate and Rayon

Acetate fibers are derived from cellulose found in wood pulp, undergoing chemical treatment with acetic acid and acetic anhydride to create a cellulose acetate solution that is then extruded into fibers. Rayon is a regenerated cellulose fiber produced by dissolving natural cellulose from sources like wood or bamboo in chemicals such as sodium hydroxide and carbon disulfide, forming a viscous solution called viscose that is spun into fibers. The key difference lies in acetate's esterification process producing a thermoplastic fiber, while rayon involves chemically transforming cellulose into viscose for a more absorbent and breathable textile.

Chemical Composition: Acetate vs Rayon

Acetate fibers are primarily composed of cellulose acetate, derived from natural cellulose that undergoes acetylation, resulting in a thermoplastic, semi-synthetic fiber with lower moisture absorption. Rayon, also called viscose, is regenerated cellulose fiber created by chemically treating natural cellulose with alkali and carbon disulfide, which restores it to a cellulose-based fiber with higher moisture retention and breathability. The distinct chemical modifications influence their physical properties, with acetate having a smoother, more lustrous appearance and rayon offering greater comfort and absorbency.

Texture and Appearance Comparison

Acetate fabric offers a smooth, glossy finish with a silky texture, making it ideal for elegant garments and linings, while rayon has a softer, more breathable feel with a matte or slightly lustrous appearance that mimics natural fibers like cotton or silk. Rayon's texture tends to be more absorbent and drapes well, enhancing comfort and versatility in apparel compared to acetate's crispness and lower moisture absorption. Both fibers provide a luxurious feel, but acetate's shine and silk-like texture contrast with rayon's natural, soft touch and matte finish.

Durability and Longevity: Which Lasts Longer?

Rayon, a semi-synthetic fiber derived from cellulose, generally offers greater durability and longevity compared to acetate, which is less resistant to wear and tear due to its lower moisture absorption and weaker fiber structure. Acetate tends to degrade faster with exposure to sunlight and heat, making rayon a preferred choice for garments requiring frequent use and longer lifespan. The enhanced tensile strength and resilience of rayon contribute to its superior performance in terms of durability and extended fabric life.

Moisture Absorption and Breathability

Rayon and acetate differ significantly in moisture absorption and breathability, with rayon absorbing moisture more efficiently due to its cellulose-based fiber structure, allowing better sweat evaporation. Acetate, derived from cellulose acetate, tends to retain less moisture and offers lower breathability, which can result in a clammy feeling during prolonged wear. Textile manufacturers often prefer rayon for garments requiring high moisture management and comfort in humid conditions.

Environmental Impact of Acetate and Rayon

Acetate, derived from cellulose acetate, involves chemical-intensive processing and generates hazardous waste, contributing to environmental concerns such as water pollution and slow biodegradability. Rayon, produced from regenerated cellulose fibers, often requires large amounts of water and energy, with some methods releasing toxic chemicals like carbon disulfide, impacting ecosystems and worker health. Sustainable sourcing of raw materials and advanced closed-loop production technologies can mitigate the environmental footprint of both acetate and rayon fibers.

Care and Maintenance: Acetate vs Rayon Fabrics

Acetate fabrics require gentle hand washing or dry cleaning to prevent shrinking and distortion, as they are sensitive to heat and water exposure. Rayon, while also delicate, can be machine washed on a gentle cycle with cold water but should be air-dried to maintain fabric integrity and avoid weakening fibers. Both fabrics benefit from low-heat ironing with a protective cloth to prevent damage, ensuring longer garment life through proper care and maintenance.

Common Applications in Fashion and Textiles

Acetate fibers are widely used in linings, dresses, and evening wear due to their luxurious sheen and smooth drape, providing a silky finish that enhances garment aesthetics. Rayon, prized for its breathability and versatility, is commonly found in casual wear, blouses, and activewear, offering comfort and moisture absorption. Both fibers serve distinct roles in fashion, with acetate preferred for formal and decorative uses, while rayon supports everyday clothing requiring softness and durability.

Choosing Between Acetate and Rayon: Which Is Better?

Acetate and rayon are both semi-synthetic fibers derived from cellulose, but acetate offers superior luster and smoothness while rayon is more absorbent and breathable. Rayon tends to be more versatile in textile applications due to its better moisture-wicking properties, making it ideal for clothing worn in warm climates. Acetate's affinity for vibrant colors and silk-like feel makes it preferred in luxury garments and linings, but rayon's durability and cost-effectiveness often position it as the better overall choice for everyday wear.

Acetate vs Rayon Infographic

materialdif.com

materialdif.com