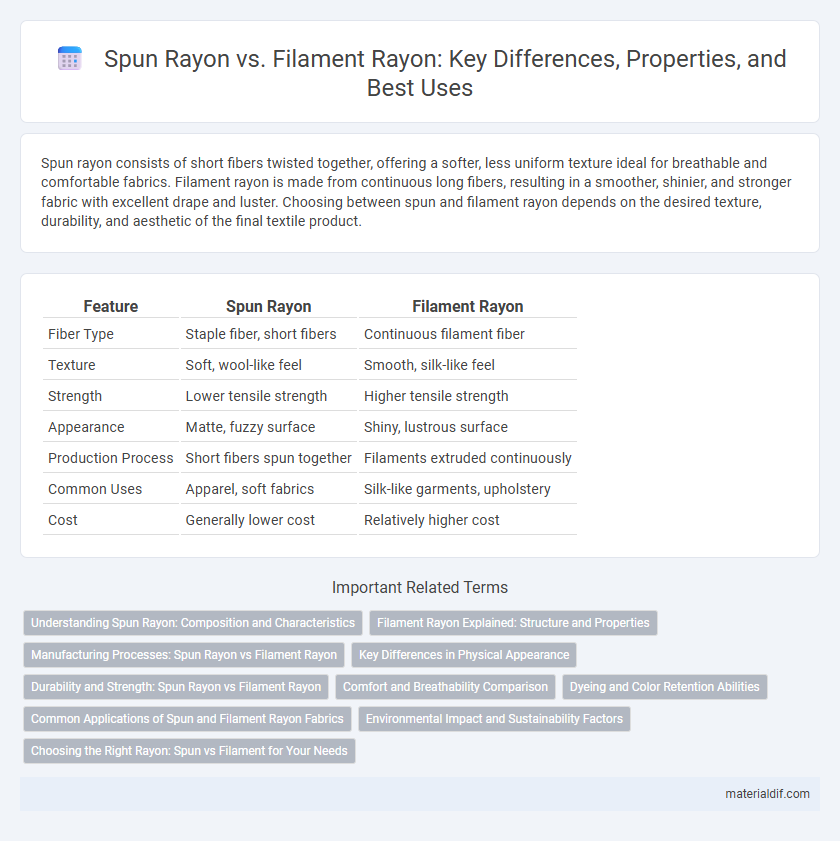

Spun rayon consists of short fibers twisted together, offering a softer, less uniform texture ideal for breathable and comfortable fabrics. Filament rayon is made from continuous long fibers, resulting in a smoother, shinier, and stronger fabric with excellent drape and luster. Choosing between spun and filament rayon depends on the desired texture, durability, and aesthetic of the final textile product.

Table of Comparison

| Feature | Spun Rayon | Filament Rayon |

|---|---|---|

| Fiber Type | Staple fiber, short fibers | Continuous filament fiber |

| Texture | Soft, wool-like feel | Smooth, silk-like feel |

| Strength | Lower tensile strength | Higher tensile strength |

| Appearance | Matte, fuzzy surface | Shiny, lustrous surface |

| Production Process | Short fibers spun together | Filaments extruded continuously |

| Common Uses | Apparel, soft fabrics | Silk-like garments, upholstery |

| Cost | Generally lower cost | Relatively higher cost |

Understanding Spun Rayon: Composition and Characteristics

Spun rayon consists of staple fibers derived from regenerated cellulose, produced by mechanically twisting short fibers into yarns, which enhances its softness and breathability. This type of rayon is characterized by a matte finish and a slightly fuzzy texture, making it ideal for textured fabrics and comfortable wear. Its composition allows for excellent dye absorption, resulting in vibrant colors and versatile fabric applications.

Filament Rayon Explained: Structure and Properties

Filament rayon consists of continuous, long fibers that provide a smooth, lustrous surface and enhanced tensile strength compared to spun rayon. Its uniform structure results in higher durability, better drape, and a silk-like feel, making it ideal for luxury textiles and high-fashion apparel. The filament form also reduces pilling and improves moisture wicking, contributing to superior comfort and performance in garments.

Manufacturing Processes: Spun Rayon vs Filament Rayon

Spun rayon is produced by cutting continuous filaments into staple fibers before spinning, using processes like carding and drawing to create a yarn resembling cotton. Filament rayon manufacturing involves extruding viscose solution through spinnerets to form long, continuous filaments that are then wound directly into yarn or fabric, offering a smooth, silk-like texture. The key difference lies in spun rayon's staple fiber assembly versus filament rayon's uninterrupted fiber length, impacting the fabric's strength and appearance.

Key Differences in Physical Appearance

Spun rayon consists of staple fibers twisted together, giving it a fuzzy texture and matte finish, while filament rayon is made from continuous filaments that create a smooth, shiny surface with uniform appearance. The staple fibers in spun rayon result in a fabric that feels softer but may have slight irregularities, whereas filament rayon offers a sleek, lustrous look and a smooth hand. These physical distinctions impact the fabric's drape, breathability, and suitability for different garment types.

Durability and Strength: Spun Rayon vs Filament Rayon

Spun rayon, made from staple fibers, exhibits a softer texture but generally has lower durability and strength compared to filament rayon, which consists of continuous fibers. Filament rayon offers enhanced tensile strength and resistance to wear, making it more suitable for high-stress applications. The strong, smooth fibers of filament rayon contribute to longer-lasting fabrics, while spun rayon's shorter fibers are prone to pilling and reduced lifespan.

Comfort and Breathability Comparison

Spun rayon, made from short fibers, offers superior softness and comfort due to its cotton-like texture, making it ideal for casual wear and sensitive skin. Filament rayon, produced from continuous fibers, provides a smoother, shinier surface with enhanced moisture-wicking properties, promoting breathability and a lightweight feel suitable for activewear. Both types ensure excellent air permeability and moisture management, but spun rayon generally excels in softness while filament rayon leads in sleekness and drying speed.

Dyeing and Color Retention Abilities

Spun rayon, made from staple fibers, offers superior dye absorption due to its porous surface, resulting in vibrant and quick color uptake. Filament rayon, composed of continuous fibers, provides smoother texture but less dye penetration, which may affect the intensity of color. Color retention in spun rayon tends to be better over time as the fiber structure holds dye molecules more firmly compared to filament rayon.

Common Applications of Spun and Filament Rayon Fabrics

Spun rayon fabric, known for its soft texture and durability, is commonly used in apparel like shirts, dresses, and casual wear where comfort and breathability are essential. Filament rayon, with a smoother and silkier finish, is favored in luxurious garments, linings, and upholstery due to its lustrous appearance and strength. Both types are also popular in home textiles, but spun rayon excels in clothing while filament rayon is preferred for high-end decorative purposes.

Environmental Impact and Sustainability Factors

Spun rayon, made from short cellulose fibers, typically results in more waste and higher water usage during production compared to filament rayon, which uses continuous fibers and offers greater efficiency and lower environmental footprint. Filament rayon's manufacturing process often incorporates closed-loop systems that recycle chemicals and water, significantly reducing pollution and energy consumption. Both types rely on sustainable sourcing of cellulose, but filament rayon's streamlined production enhances its overall sustainability profile in the textile industry.

Choosing the Right Rayon: Spun vs Filament for Your Needs

Spun rayon features staple fibers twisted together to create a soft, cotton-like texture ideal for breathable, comfortable garments, while filament rayon uses continuous filament fibers offering a smooth, lustrous finish with enhanced strength and durability. Choosing between spun and filament rayon depends on the desired fabric characteristics; spun rayon suits casual, absorbent clothing, and filament rayon excels in elegant, wrinkle-resistant apparel. Evaluate the end-use and care requirements to select the optimal rayon type for your textile project.

Spun Rayon vs Filament Rayon Infographic

materialdif.com

materialdif.com