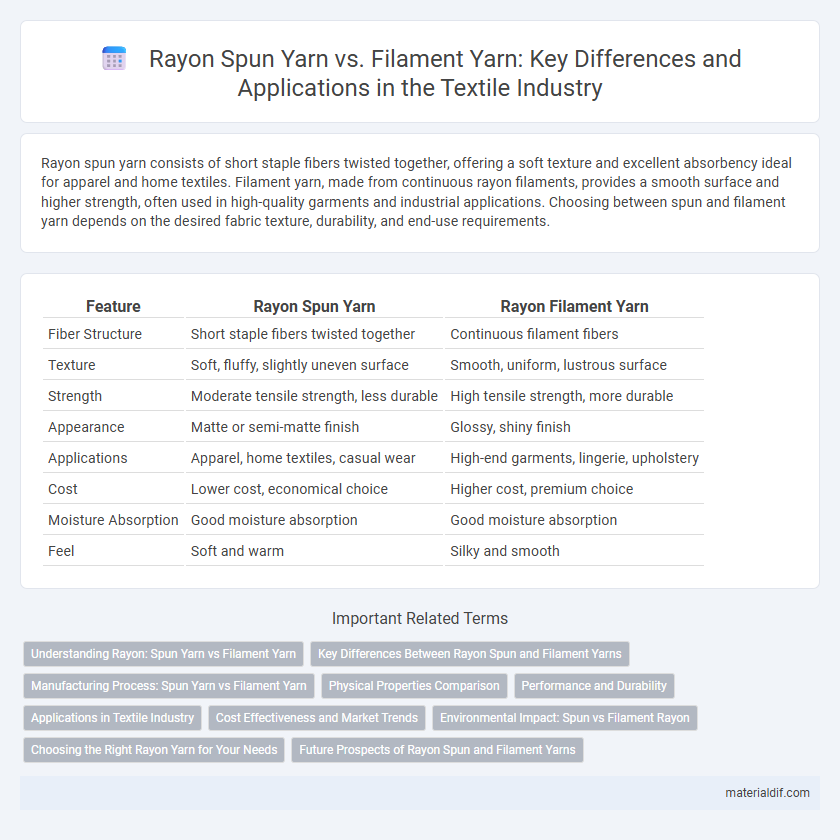

Rayon spun yarn consists of short staple fibers twisted together, offering a soft texture and excellent absorbency ideal for apparel and home textiles. Filament yarn, made from continuous rayon filaments, provides a smooth surface and higher strength, often used in high-quality garments and industrial applications. Choosing between spun and filament yarn depends on the desired fabric texture, durability, and end-use requirements.

Table of Comparison

| Feature | Rayon Spun Yarn | Rayon Filament Yarn |

|---|---|---|

| Fiber Structure | Short staple fibers twisted together | Continuous filament fibers |

| Texture | Soft, fluffy, slightly uneven surface | Smooth, uniform, lustrous surface |

| Strength | Moderate tensile strength, less durable | High tensile strength, more durable |

| Appearance | Matte or semi-matte finish | Glossy, shiny finish |

| Applications | Apparel, home textiles, casual wear | High-end garments, lingerie, upholstery |

| Cost | Lower cost, economical choice | Higher cost, premium choice |

| Moisture Absorption | Good moisture absorption | Good moisture absorption |

| Feel | Soft and warm | Silky and smooth |

Understanding Rayon: Spun Yarn vs Filament Yarn

Rayon spun yarn consists of staple fibers twisted together, offering a soft texture and excellent breathability ideal for casual wear and comfort-focused textiles. Filament rayon yarn, made from continuous fibers, provides a smooth, lustrous finish with higher tensile strength, suitable for luxury apparel and high-end home textiles. Understanding the structural differences helps in selecting the appropriate yarn type based on fabric durability, appearance, and end-use.

Key Differences Between Rayon Spun and Filament Yarns

Rayon spun yarn is made by twisting short staple fibers, resulting in a soft, breathable texture ideal for knitwear and casual fabrics, while filament yarn consists of continuous filament fibers that produce smooth, strong, and lustrous fabrics commonly used in formal and high-end apparel. Spun rayon yarns have a matte appearance and lower tensile strength compared to the filament variety, which offers higher durability and a shiny finish due to its continuous fiber structure. Filament yarns also provide better resistance to pilling and retain color vibrancy longer, making them preferable for garments requiring longevity and a polished look.

Manufacturing Process: Spun Yarn vs Filament Yarn

Rayon spun yarn is produced by drawing and twisting staple fibers extracted from regenerated cellulose, resulting in short fiber lengths that are tightly twisted together, whereas filament yarn is made from continuous, long fibers extruded through spinnerets without the need for twisting. The manufacturing process for spun yarn involves carding, combing, and spinning to align and bind staple fibers, while filament yarn requires a single step of extrusion followed by winding. This fundamental difference influences the texture, strength, and end-use applications of rayon yarns.

Physical Properties Comparison

Rayon spun yarn consists of short staple fibers twisted together, resulting in a softer, more breathable texture with moderate strength and elasticity. Filament rayon yarn is made from continuous filaments, providing a smoother surface, higher tensile strength, and improved durability. The physical properties of filament yarn yield better resistance to abrasion and less pilling compared to spun yarn, making it suitable for applications requiring enhanced fabric longevity.

Performance and Durability

Rayon spun yarn offers excellent breathability and softness, making it ideal for comfortable apparel, but it tends to have lower tensile strength and durability compared to filament yarn. Filament rayon yarn, composed of continuous fibers, provides superior strength, smoothness, and resistance to pilling, enhancing fabric longevity and performance under stress. For applications requiring a balance of comfort and durability, filament rayon yarn outperforms spun yarn in maintaining fabric integrity over time.

Applications in Textile Industry

Rayon spun yarn, composed of short staple fibers, is widely used in textile applications requiring softness and breathability such as apparel, home linens, and soft furnishings. Filament rayon yarn, made from continuous fibers, provides strength and smoothness, making it suitable for high-sheen fabrics, luxury garments, and technical textiles. The distinct structural properties of spun and filament rayon yarns drive their specific uses in knitting, weaving, embroidery, and industrial textiles within the textile industry.

Cost Effectiveness and Market Trends

Rayon spun yarn offers greater cost-effectiveness compared to filament yarn due to lower production expenses and versatility in textile applications. Market trends show increasing demand for spun yarn in fashion and home textiles, driven by its softness and breathable qualities. Filament yarn remains preferred in technical textiles and luxury fabrics, balancing cost with high-performance attributes.

Environmental Impact: Spun vs Filament Rayon

Spun rayon yarn, made from short fibers, typically requires more water and energy due to additional processing steps such as carding and spinning, increasing its environmental footprint compared to filament rayon yarn. Filament rayon yarn, produced from continuous fibers, generally has higher resource efficiency and less waste generation, resulting in a lower overall environmental impact. Choosing filament rayon yarn can contribute to more sustainable textile production by reducing water consumption, energy use, and fiber waste.

Choosing the Right Rayon Yarn for Your Needs

Rayon spun yarn, composed of short staple fibers twisted together, offers softness and breathability ideal for casual and comfortable textiles. Filament rayon yarn comprises continuous filaments, providing strength, smoothness, and a lustrous finish favored in high-end fashion and upholstery. Selecting the right rayon yarn depends on the intended fabric properties, balancing durability and texture specific to your project requirements.

Future Prospects of Rayon Spun and Filament Yarns

Rayon spun yarn continues to gain traction in sustainable fashion markets due to its biodegradability and natural fiber-like texture, appealing to eco-conscious consumers and premium brands. Filament rayon yarn is expected to see growth in industrial applications such as automotive interiors and technical textiles because of its superior strength and smooth finish. Advances in production technology and biobased raw materials will drive innovation, enhancing both spun and filament rayon yarn's performance and environmental profile.

Rayon Spun Yarn vs Filament Yarn Infographic

materialdif.com

materialdif.com