Rayon PET fibers with fibrillation exhibit surface splitting that enhances moisture absorption and breathability, making them ideal for activewear and textiles requiring high comfort. Non-fibrillated Rayon PET maintains a smooth surface, offering greater strength and durability, which suits applications in industrial fabrics and upholstery. Understanding the differences between fibrillated and non-fibrillated Rayon PET allows for optimized fabric performance tailored to specific end-use requirements.

Table of Comparison

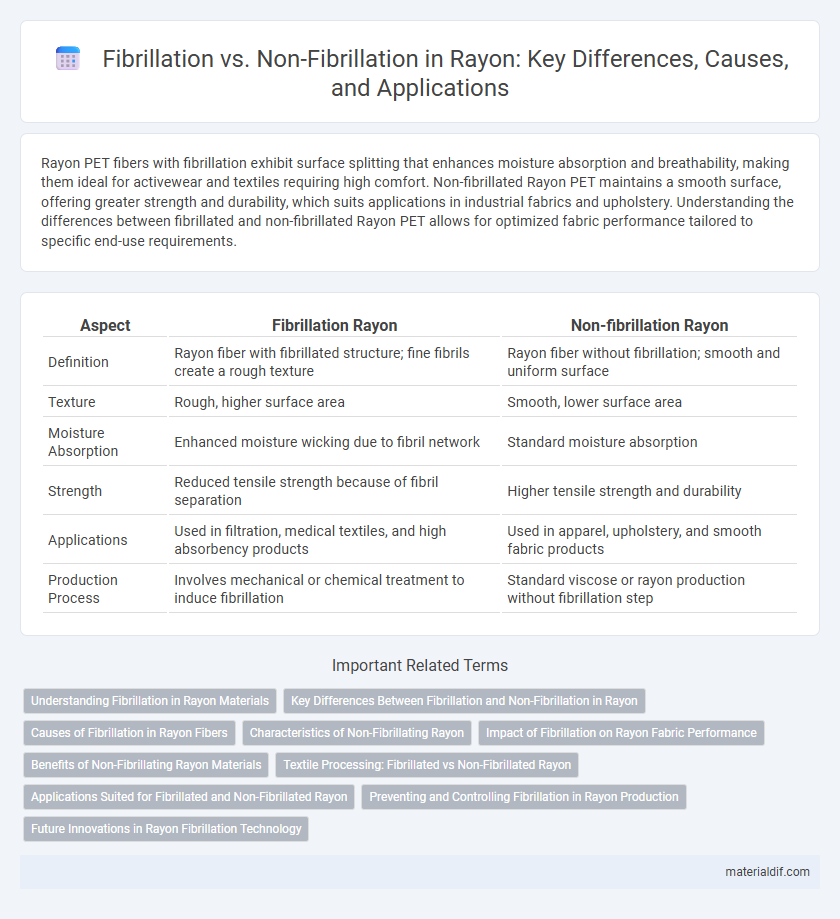

| Aspect | Fibrillation Rayon | Non-fibrillation Rayon |

|---|---|---|

| Definition | Rayon fiber with fibrillated structure; fine fibrils create a rough texture | Rayon fiber without fibrillation; smooth and uniform surface |

| Texture | Rough, higher surface area | Smooth, lower surface area |

| Moisture Absorption | Enhanced moisture wicking due to fibril network | Standard moisture absorption |

| Strength | Reduced tensile strength because of fibril separation | Higher tensile strength and durability |

| Applications | Used in filtration, medical textiles, and high absorbency products | Used in apparel, upholstery, and smooth fabric products |

| Production Process | Involves mechanical or chemical treatment to induce fibrillation | Standard viscose or rayon production without fibrillation step |

Understanding Fibrillation in Rayon Materials

Fibrillation in rayon materials refers to the formation of fine, hair-like fibrils on the fiber surface, which enhances surface area and improves dye uptake and fabric softness. Non-fibrillated rayon retains a smooth, intact fiber surface, contributing to greater strength and durability but reduced absorbency. Understanding the degree of fibrillation is crucial for optimizing rayon's performance in textile applications such as filtration, apparel, and industrial uses.

Key Differences Between Fibrillation and Non-Fibrillation in Rayon

Fibrillation in rayon occurs when fibers split into fine fibrils on the fabric surface, enhancing softness and moisture absorption but potentially reducing durability. Non-fibrillation rayon maintains smooth fiber surfaces, offering stronger fabric integrity and a sleeker appearance without the fuzzy texture. Key differences include the tactile feel, moisture management capabilities, and fabric strength, where fibrillated rayon excels in comfort while non-fibrillated rayon prioritizes durability and smoothness.

Causes of Fibrillation in Rayon Fibers

Fibrillation in rayon fibers occurs primarily due to mechanical stress during processing, which causes the fiber surface to split into fine fibrils. Chemical treatments, such as strong alkalis used in mercerization, weaken the fiber's molecular structure, increasing susceptibility to fibrillation. Improper drying and handling techniques can also exacerbate fibrillation by inducing fiber swelling and tension.

Characteristics of Non-Fibrillating Rayon

Non-fibrillating rayon exhibits smooth, continuous filaments without surface fibrils, resulting in a softer hand and enhanced luster compared to fibrillated rayon. Its production involves controlled spinning and coagulation processes that prevent the generation of microfibers, ensuring higher tensile strength and dimensional stability. This structure makes non-fibrillating rayon ideal for high-quality textiles requiring durability and a silky appearance.

Impact of Fibrillation on Rayon Fabric Performance

Fibrillation in rayon fabric creates a rougher surface texture by causing fiber splitting at the microscopic level, which increases fabric softness but reduces tensile strength and durability. This micro-level fiber damage leads to higher vulnerability to abrasion and pilling during wear, significantly impacting the fabric's lifespan and appearance. Non-fibrillated rayon maintains smoother fiber integrity, resulting in enhanced fabric strength, better moisture management, and improved overall performance in textile applications.

Benefits of Non-Fibrillating Rayon Materials

Non-fibrillating rayon materials offer enhanced durability and smoother texture compared to fibrillating counterparts, reducing fiber shedding and improving fabric longevity. Their superior resistance to abrasion and pilling makes them ideal for high-performance textiles and sensitive skin applications. These benefits contribute to increased comfort and maintenance ease in garments and industrial uses.

Textile Processing: Fibrillated vs Non-Fibrillated Rayon

Fibrillated rayon features a textured surface created by splitting fibers during mechanical processing, enhancing fabric softness, moisture absorption, and dye uptake, making it ideal for textiles requiring high absorbency and flexibility. Non-fibrillated rayon maintains smooth, continuous filaments, resulting in stronger, more uniform fabrics with a sleek appearance suitable for formal wear and applications demanding durability. The choice between fibrillated and non-fibrillated rayon directly influences fabric performance characteristics such as hand feel, strength, and moisture management in textile manufacturing.

Applications Suited for Fibrillated and Non-Fibrillated Rayon

Fibrillated rayon features a high surface area and enhanced inter-fiber bonding, making it ideal for applications such as filtration, wipes, and absorbent products that require superior strength and liquid retention. Non-fibrillated rayon maintains a smoother fiber structure, preferred in textiles and apparel where softness, drape, and sheen are critical for comfort and aesthetics. Understanding the distinct characteristics of fibrillated versus non-fibrillated rayon enables manufacturers to select the appropriate fiber type for specialized industrial uses and consumer goods.

Preventing and Controlling Fibrillation in Rayon Production

Fibrillation in rayon production refers to the formation of fine fibers on the surface of rayon filaments, which can lead to defects affecting fabric strength and appearance. Preventing fibrillation involves optimizing the cellulose solution concentration, controlling coagulation bath parameters such as temperature and composition, and carefully adjusting the stretching ratio during filament drawing. Non-fibrillation rayon production enhances fiber uniformity and durability by minimizing surface fiber breakage through precise process controls and chemical treatment adjustments.

Future Innovations in Rayon Fibrillation Technology

Future innovations in rayon fibrillation technology aim to enhance fiber surface properties by precisely controlling microfibril formation, leading to improved fabric softness and dye affinity. Advanced enzymatic treatments and nanotechnology integration are being developed to optimize fibrillation without compromising fiber strength or environmental sustainability. These breakthroughs promise to revolutionize textile manufacturing by balancing performance, eco-friendliness, and cost-effectiveness in rayon production.

Fibrillation vs Non-fibrillation Infographic

materialdif.com

materialdif.com