Regenerated cellulose fibers like rayon offer a versatile alternative to natural fibers by combining the benefits of both natural origin and engineered performance. Unlike natural fibers such as cotton or wool, rayon provides enhanced softness, breathability, and moisture absorption due to its unique manufacturing process. This blend of natural cellulose base and modern regeneration techniques results in fibers that are sustainable, biodegradable, and highly adaptable for various textile applications.

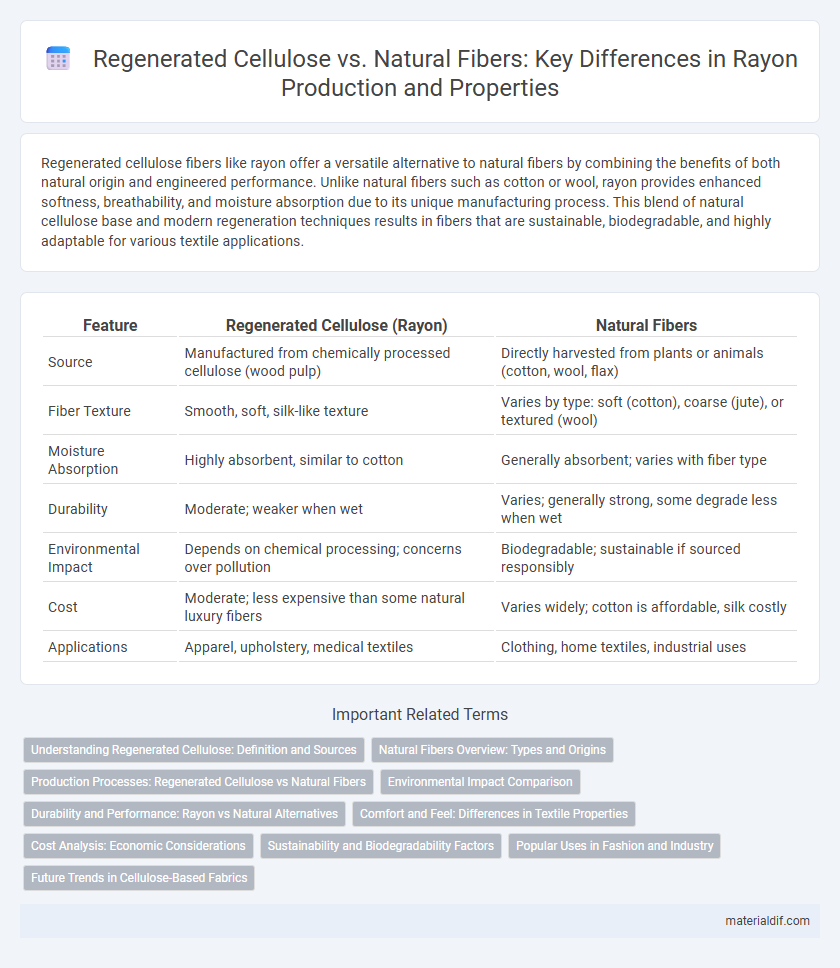

Table of Comparison

| Feature | Regenerated Cellulose (Rayon) | Natural Fibers |

|---|---|---|

| Source | Manufactured from chemically processed cellulose (wood pulp) | Directly harvested from plants or animals (cotton, wool, flax) |

| Fiber Texture | Smooth, soft, silk-like texture | Varies by type: soft (cotton), coarse (jute), or textured (wool) |

| Moisture Absorption | Highly absorbent, similar to cotton | Generally absorbent; varies with fiber type |

| Durability | Moderate; weaker when wet | Varies; generally strong, some degrade less when wet |

| Environmental Impact | Depends on chemical processing; concerns over pollution | Biodegradable; sustainable if sourced responsibly |

| Cost | Moderate; less expensive than some natural luxury fibers | Varies widely; cotton is affordable, silk costly |

| Applications | Apparel, upholstery, medical textiles | Clothing, home textiles, industrial uses |

Understanding Regenerated Cellulose: Definition and Sources

Regenerated cellulose is a type of fiber made by chemically converting natural cellulose from plants like wood pulp, bamboo, and cotton linters into a soluble form before spinning it into fibers such as rayon, modal, and lyocell. Unlike natural fibers that are directly harvested from plants or animals, regenerated cellulose involves a manufacturing process that retains the benefits of natural cellulose while enhancing properties like softness and moisture absorbency. Common sources for regenerated cellulose include wood from fast-growing trees, which supports sustainable production compared to traditional natural fibers like cotton that require intensive water and pesticide use.

Natural Fibers Overview: Types and Origins

Natural fibers, sourced from plants, animals, and minerals, include cotton, wool, silk, flax, jute, and hemp, each with distinct properties and origins. Plant-based fibers like cotton and flax are cellulose-rich and derived from seeds or stems, while animal fibers such as wool and silk are protein-based, obtained from the coats of sheep and silkworms respectively. Their biodegradability, breathability, and renewable nature make natural fibers popular choices in sustainable textiles compared to regenerated cellulose fibers like rayon.

Production Processes: Regenerated Cellulose vs Natural Fibers

Regenerated cellulose fibers, such as rayon, are produced by chemically processing natural cellulose from wood pulp or cotton linters, involving steps like cellulose extraction, purification, and regeneration through dissolution and spinning. In contrast, natural fibers like cotton, flax, or wool are harvested directly from plants or animals and undergo minimal mechanical or chemical treatment before being spun into yarn. The production of regenerated cellulose allows for controlled fiber properties and mass production, whereas natural fibers retain their intrinsic biological structure and variability.

Environmental Impact Comparison

Regenerated cellulose fibers like rayon are derived from natural cellulose sources but undergo extensive chemical processing, resulting in higher water consumption and potential release of harmful chemicals compared to natural fibers such as cotton or wool. Natural fibers typically have lower environmental footprints due to minimal processing, biodegradability, and fewer chemical inputs during cultivation. However, advancements in eco-friendly rayon production methods, including closed-loop systems, are reducing environmental impacts, positioning regenerated cellulose as a more sustainable alternative to synthetic textiles.

Durability and Performance: Rayon vs Natural Alternatives

Rayon, a regenerated cellulose fiber, offers enhanced softness and breathability compared to many natural fibers like cotton and wool, but it generally lacks their durability and tensile strength. Unlike natural fibers, rayon is more prone to weakening when wet and may degrade faster with prolonged exposure to sunlight, impacting its long-term performance. Innovations in fiber treatment and blending have improved rayon's resilience, yet natural fibers often remain preferable for applications requiring high durability and structural integrity.

Comfort and Feel: Differences in Textile Properties

Regenerated cellulose fibers like rayon offer a smooth, silky texture and excellent moisture absorption, enhancing comfort compared to many natural fibers such as cotton and wool. Rayon's breathability and softness make it ideal for sensitive skin, while natural fibers often provide superior insulation and durability. The choice between regenerated cellulose and natural fibers depends on the desired balance of softness, breathability, and resilience in textile applications.

Cost Analysis: Economic Considerations

Regenerated cellulose fibers, such as rayon, often present a cost-effective alternative to natural fibers due to lower raw material expenses and scalable production methods. The manufacturing process for rayon allows for consistent output and reduced reliance on agricultural variables, which can affect natural fiber prices like cotton or wool. Despite higher energy and chemical input costs, rayon typically offers more competitive pricing, benefiting large-scale textile production and budget-sensitive markets.

Sustainability and Biodegradability Factors

Regenerated cellulose fibers, including rayon, are derived from natural cellulose sources like wood pulp, offering enhanced sustainability compared to synthetic fibers due to their renewable origin and lower carbon footprint. Unlike many synthetic fibers, regenerated cellulose is biodegradable, decomposing more rapidly in natural environments and reducing long-term ecological impact. However, the sustainability of regenerated cellulose varies significantly depending on the raw material sourcing and manufacturing practices, with responsibly managed forestry and closed-loop production processes optimizing environmental benefits compared to some natural fibers that may involve intensive water and pesticide use.

Popular Uses in Fashion and Industry

Regenerated cellulose fibers like rayon are widely used in fashion for their silk-like texture and affordability, serving as an alternative to expensive natural fibers such as silk and cotton. In the industry, rayon's versatility enables applications in upholstery, medical supplies, and tire cords, benefiting from its breathability and moisture absorption. Unlike natural fibers, rayon offers customizable properties through chemical processing, making it ideal for various textile innovations and sustainability efforts.

Future Trends in Cellulose-Based Fabrics

Regenerated cellulose fibers like rayon exhibit enhanced versatility and sustainability compared to natural fibers, driven by advances in eco-friendly production methods and biodegradable properties. Innovations in chemical processing and bio-based solvents aim to reduce environmental impact while improving fiber performance and durability. The future of cellulose-based fabrics hinges on integrating circular economy principles and developing smart textiles with functional properties such as moisture management and UV protection.

Regenerated Cellulose vs Natural Fibers Infographic

materialdif.com

materialdif.com