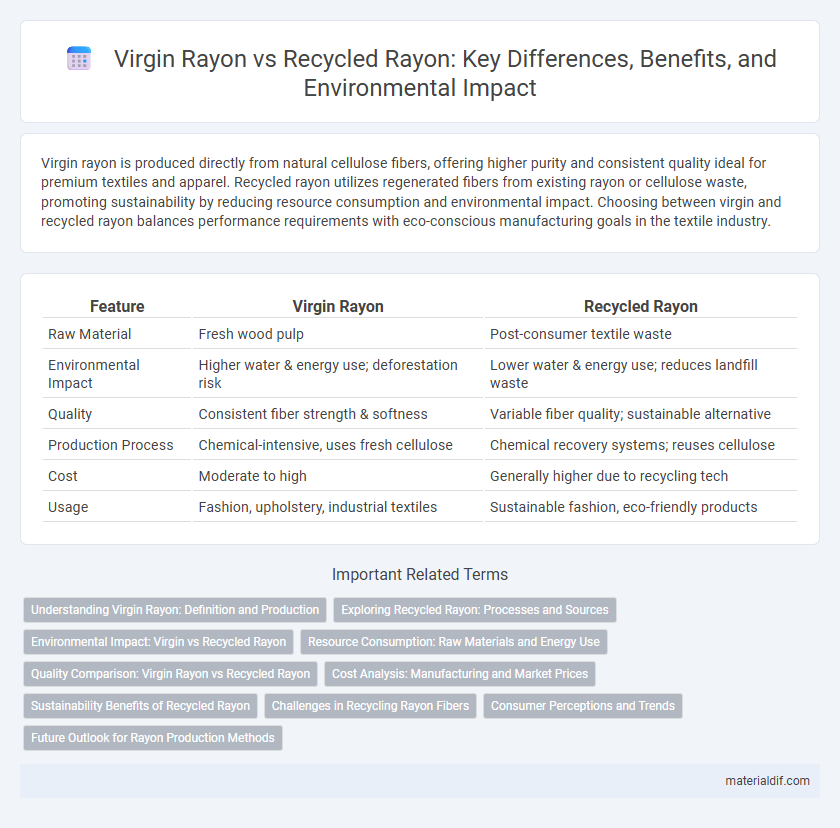

Virgin rayon is produced directly from natural cellulose fibers, offering higher purity and consistent quality ideal for premium textiles and apparel. Recycled rayon utilizes regenerated fibers from existing rayon or cellulose waste, promoting sustainability by reducing resource consumption and environmental impact. Choosing between virgin and recycled rayon balances performance requirements with eco-conscious manufacturing goals in the textile industry.

Table of Comparison

| Feature | Virgin Rayon | Recycled Rayon |

|---|---|---|

| Raw Material | Fresh wood pulp | Post-consumer textile waste |

| Environmental Impact | Higher water & energy use; deforestation risk | Lower water & energy use; reduces landfill waste |

| Quality | Consistent fiber strength & softness | Variable fiber quality; sustainable alternative |

| Production Process | Chemical-intensive, uses fresh cellulose | Chemical recovery systems; reuses cellulose |

| Cost | Moderate to high | Generally higher due to recycling tech |

| Usage | Fashion, upholstery, industrial textiles | Sustainable fashion, eco-friendly products |

Understanding Virgin Rayon: Definition and Production

Virgin rayon is a type of regenerated cellulose fiber produced directly from natural wood pulp, without any prior usage or processing. Its production involves chemical treatments such as the viscose process, where cellulose is dissolved and reformed into fibers, ensuring high purity and strength. Understanding virgin rayon's origin and manufacturing methods highlights its role in creating smooth, breathable textiles compared to recycled alternatives.

Exploring Recycled Rayon: Processes and Sources

Recycled rayon is produced by reclaiming cellulose fibers from post-consumer or industrial waste, such as discarded textiles or wood pulp rejects, reducing reliance on virgin wood resources. The recycling process typically involves chemical treatments to break down fibers, followed by regeneration into new rayon fibers while maintaining quality and strength. Sourcing recycled rayon from sustainable raw materials supports circular economy practices, minimizes deforestation, and lowers environmental impact compared to virgin rayon production.

Environmental Impact: Virgin vs Recycled Rayon

Virgin rayon is produced from freshly harvested wood pulp, leading to deforestation and high water consumption, which significantly impacts ecosystems and carbon emissions. Recycled rayon utilizes waste fibers from textiles and other sources, reducing raw material demand and lowering energy use by up to 50% compared to virgin rayon production. Choosing recycled rayon supports waste diversion from landfills and decreases the overall environmental footprint associated with rayon textile manufacturing.

Resource Consumption: Raw Materials and Energy Use

Virgin rayon production relies heavily on fresh wood pulp from trees, requiring significant raw material input and high energy consumption during chemical processing. Recycled rayon utilizes regenerated cellulose fibers from post-consumer textile waste or production scraps, significantly reducing the demand for virgin wood and lowering energy usage. This shift in raw material sourcing and processing translates into a smaller environmental footprint, conserving natural resources and decreasing overall energy consumption.

Quality Comparison: Virgin Rayon vs Recycled Rayon

Virgin rayon is produced from pure cellulose extracted from natural wood pulp, resulting in fibers with superior strength, smoothness, and consistent texture. Recycled rayon, derived from repurposed cellulose materials such as post-consumer textiles, may exhibit slight variations in fiber quality, including reduced tensile strength and uneven texture due to processing limitations. The quality comparison reveals that virgin rayon typically offers enhanced durability and a more uniform appearance, while recycled rayon provides eco-friendly benefits at the potential cost of some performance characteristics.

Cost Analysis: Manufacturing and Market Prices

Virgin rayon production involves higher raw material costs due to the use of fresh cellulose from wood pulp, resulting in increased energy consumption and chemical treatment expenses during manufacturing. Recycled rayon reduces costs by utilizing pre-consumer or post-consumer textile waste, lowering raw material and disposal fees, but recycling processes can incur added expenses in sorting and decontamination. Market prices for virgin rayon typically exceed recycled rayon, reflecting the premium on purity and performance, while recycled rayon offers competitive pricing driven by sustainability trends and resource efficiency.

Sustainability Benefits of Recycled Rayon

Recycled rayon significantly reduces environmental impact by utilizing post-consumer and pre-consumer cellulose waste, minimizing deforestation and lowering water and energy consumption compared to virgin rayon production. It helps divert textile waste from landfills, promoting circular economy practices within the fashion and textile industries. Embracing recycled rayon supports sustainable resource management and reduces carbon emissions associated with the production of virgin fibers.

Challenges in Recycling Rayon Fibers

Recycling rayon fibers poses significant challenges due to their cellulose-based composition, which complicates separation from blended fabrics and results in fiber degradation, reducing quality and durability. Virgin rayon production uses raw cellulose sources like wood pulp, ensuring consistent fiber strength and purity, whereas recycled rayon often suffers from contamination and shorter fiber length, limiting its reuse potential. Innovations in chemical recycling and enzymatic treatments are essential to improve the efficiency and environmental impact of recycled rayon fiber processing.

Consumer Perceptions and Trends

Virgin rayon, produced from fresh cellulose fibers, is often perceived by consumers as offering superior softness and durability compared to recycled rayon. Recycled rayon, made from repurposed textiles or waste materials, appeals to environmentally conscious consumers seeking sustainable and eco-friendly fabric options. Market trends indicate a growing demand for recycled rayon driven by increasing awareness of textile waste and a shift towards circular fashion.

Future Outlook for Rayon Production Methods

Virgin rayon production relies on cellulose derived primarily from sustainably managed trees, ensuring high fiber purity and versatility for various textile applications. Recycled rayon, made from post-consumer and post-industrial waste, offers a lower environmental footprint by reducing deforestation and waste, aligning with growing circular economy demands. Future outlooks for rayon production emphasize advanced chemical recovery systems and sustainable raw material sourcing, aiming for scalable eco-friendly processes without compromising fiber quality.

Virgin Rayon vs Recycled Rayon Infographic

materialdif.com

materialdif.com