Rayon dyeing offers vibrant, long-lasting colors due to its high absorbency and smooth fiber structure, which allows for deeper pigment penetration compared to cotton dyeing. Cotton fibers absorb dye less uniformly, often requiring additional chemicals and processes to achieve similar color intensity and fastness. This difference in dye affinity makes rayon fabrics particularly suitable for rich, vivid prints and smooth finishes in textile applications.

Table of Comparison

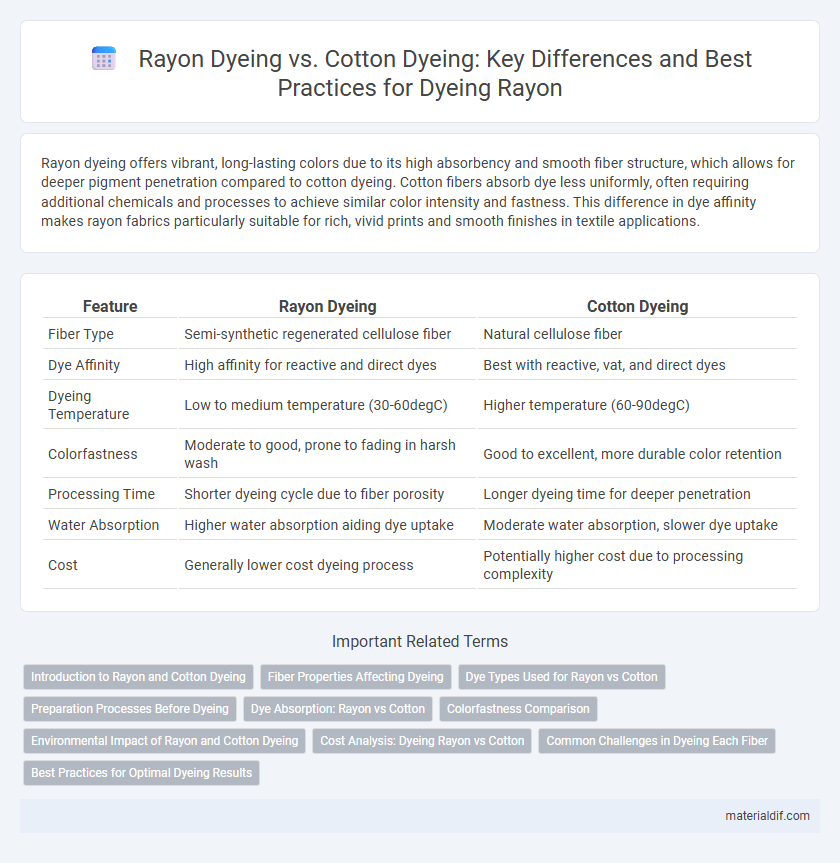

| Feature | Rayon Dyeing | Cotton Dyeing |

|---|---|---|

| Fiber Type | Semi-synthetic regenerated cellulose fiber | Natural cellulose fiber |

| Dye Affinity | High affinity for reactive and direct dyes | Best with reactive, vat, and direct dyes |

| Dyeing Temperature | Low to medium temperature (30-60degC) | Higher temperature (60-90degC) |

| Colorfastness | Moderate to good, prone to fading in harsh wash | Good to excellent, more durable color retention |

| Processing Time | Shorter dyeing cycle due to fiber porosity | Longer dyeing time for deeper penetration |

| Water Absorption | Higher water absorption aiding dye uptake | Moderate water absorption, slower dye uptake |

| Cost | Generally lower cost dyeing process | Potentially higher cost due to processing complexity |

Introduction to Rayon and Cotton Dyeing

Rayon dyeing involves the application of dyes to a semi-synthetic fiber derived from cellulose, offering excellent absorbency and vibrant color results due to its porous structure. Cotton dyeing, by contrast, deals with a natural cellulose fiber known for its durability and ability to retain color well under various dyeing methods such as reactive, vat, and direct dyes. Understanding the chemical and physical differences between rayon and cotton fibers is crucial for optimizing dye selection, processing conditions, and achieving desired colorfastness and fabric performance.

Fiber Properties Affecting Dyeing

Rayon exhibits higher affinity for dyes compared to cotton due to its semi-synthetic cellulose structure, allowing deeper dye penetration and more vibrant colors. The hydrophilic nature and higher moisture regain of rayon fibers enhance dye absorption, whereas cotton's crystalline cellulose structure limits dye uptake and results in lighter shades. Furthermore, rayon's uniform fiber surface promotes consistent dyeing, while cotton's natural waxes and impurities can cause uneven color distribution during the dyeing process.

Dye Types Used for Rayon vs Cotton

Rayon dyeing commonly utilizes disperse dyes and reactive dyes due to its semi-synthetic cellulose fiber composition, enabling vibrant color absorption and durability. Cotton dyeing primarily relies on reactive dyes and direct dyes, capitalizing on its natural cellulose fibers for strong fiber-dye bonding and wash fastness. The chemical affinity of reactive dyes makes them suitable for both, but disperse dyes are uniquely effective in penetrating the regenerated cellulose structure of rayon.

Preparation Processes Before Dyeing

Preparation processes for rayon dyeing involve thorough washing and bleaching to remove natural oils and impurities due to its semi-synthetic nature, enhancing dye absorption and color vibrancy. In contrast, cotton dyeing requires scouring and mercerization to increase fiber affinity and dye uptake, improving color fastness and brightness. Both fibers demand meticulous preparation, but rayon's process emphasizes chemical treatments to modify fiber structure, while cotton focuses on cellulose purity and fiber swelling.

Dye Absorption: Rayon vs Cotton

Rayon exhibits superior dye absorption compared to cotton due to its hydrophilic nature and semi-synthetic cellulose structure, allowing it to bond more effectively with reactive and direct dyes. Cotton, a natural fiber composed of pure cellulose, requires stronger mordants and longer dyeing times to achieve comparable color vibrancy and fastness. The enhanced dye absorption of rayon results in brighter, more uniform colors, making it a preferred choice for applications demanding high-quality dyeing outcomes.

Colorfastness Comparison

Rayon dyeing often demonstrates superior color absorption compared to cotton due to its semi-synthetic cellulose composition, which allows dyes to penetrate more deeply, resulting in enhanced colorfastness. Cotton fibers, being natural and more crystalline, typically show lower dye affinity, leading to quicker fading under washing and sunlight exposure. Consequently, rayon garments maintain vibrant coloration longer than cotton when subjected to repeated laundering and UV light.

Environmental Impact of Rayon and Cotton Dyeing

Rayon dyeing consumes significantly more water and energy compared to cotton dyeing, intensifying its environmental footprint despite rayon's semi-synthetic origin. The chemical processes used in rayon production release hazardous pollutants such as carbon disulfide and sulfuric acid, contributing to water and air contamination. In contrast, cotton dyeing impacts arise mainly from intensive pesticide use during cultivation, but advancements in organic cotton and waterless dyeing technologies are reducing its ecological effects.

Cost Analysis: Dyeing Rayon vs Cotton

Dyeing rayon typically incurs higher costs compared to cotton due to the need for specialized chemicals and controlled temperature processes to preserve fiber integrity and achieve vibrant colors. Cotton dyeing benefits from well-established, cost-efficient methods like reactive and vat dyeing that reduce chemical usage and energy consumption. Overall, rayon dyeing demands more investment in materials and process controls, resulting in increased operational expenses relative to cotton dyeing.

Common Challenges in Dyeing Each Fiber

Rayon dyeing often faces challenges such as uneven color absorption and fiber swelling due to its semi-synthetic cellulose structure, requiring precise temperature and chemical control. Cotton dyeing presents difficulties with achieving deep, uniform color because of its tightly packed cellulose fibers, which can resist dye penetration and cause uneven shades. Both fibers demand careful selection of dye types and fixation processes to overcome issues like color fading and poor wash fastness.

Best Practices for Optimal Dyeing Results

Rayon dyeing requires careful control of water temperature and pH levels to prevent fiber damage and achieve vibrant color absorption, unlike cotton which is more tolerant to varying conditions. Using reactive or direct dyes optimized for rayon ensures better penetration and colorfastness, while pre-treating the fiber with appropriate mordants enhances dye affinity. Consistent agitation and thorough rinsing during the dyeing process reduce uneven dye uptake and improve overall fabric uniformity for both materials.

Rayon Dyeing vs Cotton Dyeing Infographic

materialdif.com

materialdif.com