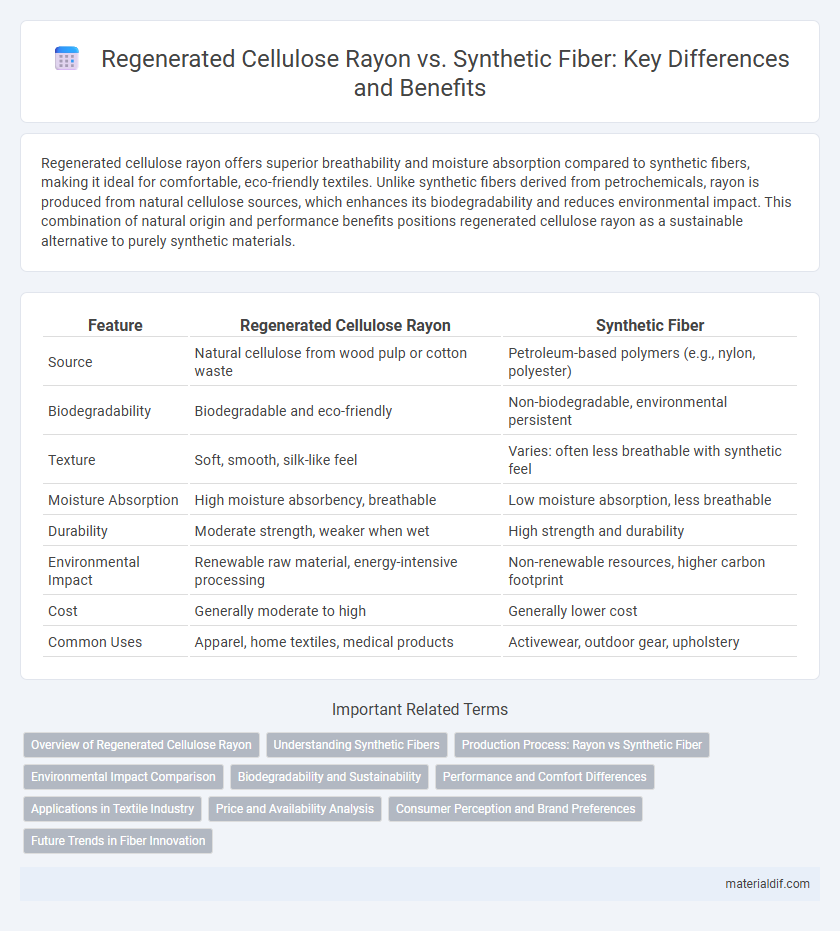

Regenerated cellulose rayon offers superior breathability and moisture absorption compared to synthetic fibers, making it ideal for comfortable, eco-friendly textiles. Unlike synthetic fibers derived from petrochemicals, rayon is produced from natural cellulose sources, which enhances its biodegradability and reduces environmental impact. This combination of natural origin and performance benefits positions regenerated cellulose rayon as a sustainable alternative to purely synthetic materials.

Table of Comparison

| Feature | Regenerated Cellulose Rayon | Synthetic Fiber |

|---|---|---|

| Source | Natural cellulose from wood pulp or cotton waste | Petroleum-based polymers (e.g., nylon, polyester) |

| Biodegradability | Biodegradable and eco-friendly | Non-biodegradable, environmental persistent |

| Texture | Soft, smooth, silk-like feel | Varies: often less breathable with synthetic feel |

| Moisture Absorption | High moisture absorbency, breathable | Low moisture absorption, less breathable |

| Durability | Moderate strength, weaker when wet | High strength and durability |

| Environmental Impact | Renewable raw material, energy-intensive processing | Non-renewable resources, higher carbon footprint |

| Cost | Generally moderate to high | Generally lower cost |

| Common Uses | Apparel, home textiles, medical products | Activewear, outdoor gear, upholstery |

Overview of Regenerated Cellulose Rayon

Regenerated Cellulose Rayon is a semi-synthetic fiber derived from natural cellulose sources such as wood pulp, offering biodegradability and breathability that synthetic fibers lack. It undergoes a chemical process to transform cellulose into a versatile fabric with a soft texture and excellent moisture absorption, making it ideal for clothing and home textiles. Compared to synthetic fibers like polyester and nylon, regenerated cellulose rayon provides enhanced comfort and environmental sustainability due to its renewable raw materials and biodegradability.

Understanding Synthetic Fibers

Synthetic fibers, such as polyester, nylon, and acrylic, are man-made materials derived primarily from petrochemicals, offering durability, elasticity, and resistance to wrinkles and shrinking. Unlike regenerated cellulose rayon, which is produced from natural cellulose sources like wood pulp through a chemical process, synthetic fibers rely on polymerization to create fibers with consistent properties. Understanding the molecular structure of synthetic fibers reveals their hydrophobic nature, which contrasts with the absorbency and breathability of regenerated cellulose rayon.

Production Process: Rayon vs Synthetic Fiber

Regenerated cellulose rayon is produced by chemically dissolving natural cellulose from wood pulp or cotton linters, then regenerating it into fibers through a wet spinning process, which makes it biodegradable and environmentally friendly compared to synthetic fibers. Synthetic fibers, such as polyester and nylon, are created through petrochemical polymerization processes involving the polymerization of monomers derived from crude oil, which are energy-intensive and result in non-biodegradable materials. The production of rayon incorporates natural raw materials and involves fewer toxic byproducts than synthetic fiber manufacturing, which relies heavily on fossil fuels and generates significant greenhouse gas emissions.

Environmental Impact Comparison

Regenerated cellulose rayon is derived from natural cellulose fibers, making it biodegradable and more sustainable compared to synthetic fibers, which are petroleum-based and non-biodegradable. The production of rayon involves chemical processing that can cause environmental pollution if not managed properly, but it generally has a lower carbon footprint and reduces reliance on fossil fuels. Synthetic fibers like polyester contribute significantly to microplastic pollution and have higher energy consumption during manufacturing, intensifying their environmental impact relative to regenerated cellulose rayon.

Biodegradability and Sustainability

Regenerated cellulose rayon, derived from natural cellulose fibers, offers superior biodegradability compared to synthetic fibers such as polyester and nylon, which are petroleum-based and persist in the environment for hundreds of years. Rayon biodegrades more rapidly under natural conditions, reducing landfill accumulation and minimizing microplastic pollution. Sustainable production practices in rayon manufacturing, including sourcing from responsibly managed forests and utilizing closed-loop processes, further enhance its environmental benefits over synthetic alternatives.

Performance and Comfort Differences

Regenerated cellulose rayon offers superior breathability and moisture absorption compared to synthetic fibers like polyester and nylon, enhancing wearer comfort in warm conditions. Rayon's natural origin provides a softer hand feel and better drape, making it ideal for garments requiring fluidity and comfort. Synthetic fibers excel in durability and wrinkle resistance but often lack the moisture management properties that make rayon favorable for everyday wear.

Applications in Textile Industry

Regenerated cellulose rayon offers superior moisture absorbency and breathability compared to synthetic fibers, making it ideal for apparel and home textiles. Its biodegradability and natural fiber-like feel enhance comfort and sustainability in fashion and upholstery applications. Synthetic fibers, while durable and wrinkle-resistant, often lack the eco-friendly properties crucial for growing environmentally conscious textile markets.

Price and Availability Analysis

Regenerated cellulose rayon typically offers a more cost-effective option compared to many synthetic fibers, with prices influenced by raw material availability from natural cellulose sources like wood pulp. Its widespread production infrastructure and renewable resource base ensure consistent market availability, whereas synthetic fibers often rely on petrochemical feedstocks subject to price volatility and supply chain disruptions. The balance of affordability and steady supply makes rayon a competitive choice in textile manufacturing, particularly for eco-conscious brands seeking sustainable alternatives.

Consumer Perception and Brand Preferences

Regenerated cellulose rayon is widely perceived by consumers as a more sustainable and eco-friendly textile option compared to synthetic fibers derived from petrochemicals. Brands focusing on environmental responsibility often prefer rayon due to its biodegradability and natural origin, which enhances their market appeal among eco-conscious buyers. Consumer preference trends increasingly favor regenerated cellulose rayon for its softness, breathability, and reduced environmental impact, positioning it as a premium choice over synthetic alternatives.

Future Trends in Fiber Innovation

Regenerated cellulose rayon, derived from natural cellulose sources, is gaining traction in fiber innovation due to its sustainability and biodegradability compared to petroleum-based synthetic fibers. Future trends emphasize enhancing the environmental profile of rayon through closed-loop production processes and bio-based chemical additives, aiming to reduce carbon footprint and water consumption. Advances in nanotechnology and fiber blending promise to improve the durability and functionality of regenerated cellulose rayon, positioning it as a competitive alternative in eco-conscious textile markets.

Regenerated Cellulose Rayon vs Synthetic Fiber Infographic

materialdif.com

materialdif.com