Rayon printing and viscose printing both involve similar processes since viscose is a type of rayon, but they differ primarily in fabric origin and texture, impacting print vibrancy and durability. Rayon printing often yields brighter, more vivid patterns due to its smooth finish, while viscose printing typically results in softer, more muted designs, reflecting its semi-synthetic fiber composition. Choosing between rayon and viscose printing depends on the desired fabric feel, print quality, and end-use application.

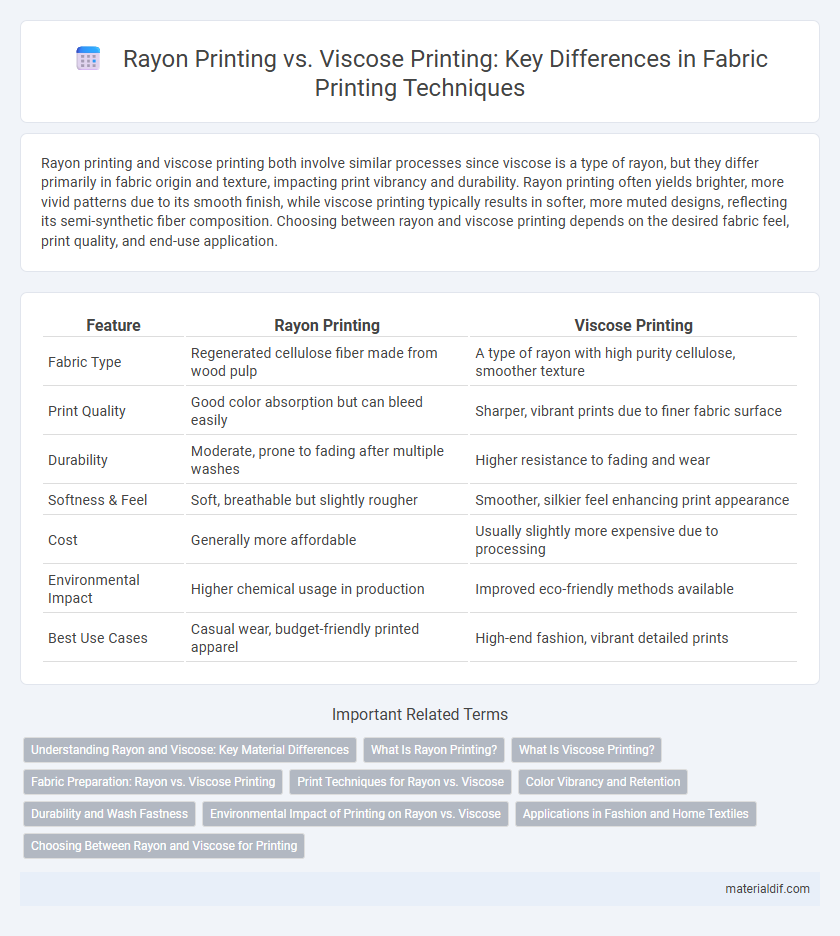

Table of Comparison

| Feature | Rayon Printing | Viscose Printing |

|---|---|---|

| Fabric Type | Regenerated cellulose fiber made from wood pulp | A type of rayon with high purity cellulose, smoother texture |

| Print Quality | Good color absorption but can bleed easily | Sharper, vibrant prints due to finer fabric surface |

| Durability | Moderate, prone to fading after multiple washes | Higher resistance to fading and wear |

| Softness & Feel | Soft, breathable but slightly rougher | Smoother, silkier feel enhancing print appearance |

| Cost | Generally more affordable | Usually slightly more expensive due to processing |

| Environmental Impact | Higher chemical usage in production | Improved eco-friendly methods available |

| Best Use Cases | Casual wear, budget-friendly printed apparel | High-end fashion, vibrant detailed prints |

Understanding Rayon and Viscose: Key Material Differences

Rayon and viscose are both semi-synthetic fibers derived from cellulose, but rayon encompasses a broader category that includes viscose as its most common type. Unlike viscose, which is produced through a specific chemical process involving carbon disulfide, other forms of rayon may use alternative methods resulting in variations in fiber strength, texture, and environmental impact. These material differences directly influence printing quality, color retention, and fabric durability, making it critical to understand the specific type of rayon when selecting fabric for printing purposes.

What Is Rayon Printing?

Rayon printing involves applying vibrant and detailed designs onto rayon fabric, a semi-synthetic fiber made from regenerated cellulose, known for its smooth texture and breathability. Unlike viscose printing, which specifically targets viscose fibers--a common type of rayon--rayon printing encompasses a broader range of cellulose-based fibers, ensuring compatibility with various fabric blends. This printing method enhances the fabric's aesthetic appeal while maintaining its softness and drape, making it ideal for fashion and home textiles.

What Is Viscose Printing?

Viscose printing involves applying designs onto viscose fabric, a type of rayon made from regenerated cellulose fibers derived from wood pulp. This printing technique enhances the smooth, silky texture and vibrant color absorption properties unique to viscose fibers, resulting in high-quality printed textiles. Compared to other rayon fabrics, viscose printing demands specific ink formulations to maintain fabric breathability and avoid fiber damage during the dyeing process.

Fabric Preparation: Rayon vs. Viscose Printing

Rayon fabric preparation for printing involves thorough cleaning and steaming to enhance dye absorption and prevent color bleeding, as its cellulose fibers are more delicate compared to viscose. Viscose printing preparation requires less intensive washing but emphasizes moisture control to maintain fabric integrity and improve print definition. Both fabrics benefit from precise temperature and humidity regulation during preparation to ensure vibrant, long-lasting prints.

Print Techniques for Rayon vs. Viscose

Rayon printing often utilizes direct printing and discharge printing techniques due to its smooth texture and absorbency, enabling vibrant and detailed designs. Viscose printing, while similar, requires adjusted ink formulations and lower heat settings during fixation to prevent fiber damage and maintain fabric integrity. Both fabrics benefit from digital printing methods, but the choice of printing technique depends on the specific fiber treatment and desired print durability.

Color Vibrancy and Retention

Rayon printing often results in more vibrant colors due to its smooth fiber surface, which allows dyes to adhere effectively, enhancing color intensity. Viscose printing provides good initial color vibrancy but may experience faster fading over time because of its slightly hollow fiber structure that absorbs dyes less uniformly. Retention is typically higher in rayon prints, making them preferable for applications requiring long-lasting color brilliance in textiles.

Durability and Wash Fastness

Rayon printing offers moderate durability but tends to fade faster compared to viscose printing, which is known for superior wash fastness and color retention. Viscose printing maintains its vibrancy through multiple washes due to its denser fiber structure, making it more resistant to wear and tear. The enhanced durability of viscose printing makes it the preferred choice for garments requiring longevity and frequent laundering.

Environmental Impact of Printing on Rayon vs. Viscose

Printing on rayon typically results in lower environmental impact compared to viscose printing due to rayon's renewable cellulose base and more eco-friendly manufacturing processes. Viscose production involves chemically intensive steps that can release harmful pollutants, whereas rayon printing often utilizes water-based inks that reduce chemical runoff. Both fabrics benefit from sustainable printing innovations, but rayon's inherently cleaner production makes its printing footprint comparatively smaller.

Applications in Fashion and Home Textiles

Rayon printing offers vibrant color retention and smooth texture, making it ideal for fashionable apparel such as dresses and blouses that require breathable fabrics with a luxurious feel. Viscose printing, often used in both fashion and home textiles, provides a soft drape and high absorbency, perfect for curtains, upholstery, and casual wear. The choice between rayon and viscose printing depends on fabric composition and end-use, with rayon favored for lightweight, flowy garments and viscose for durable home decor items.

Choosing Between Rayon and Viscose for Printing

Rayon and viscose, both semi-synthetic fibers derived from cellulose, offer distinct printing characteristics that influence fabric choice. Rayon printing typically yields vibrant colors and a smooth finish due to its high absorbency and fine fiber structure, making it ideal for intricate designs. Viscose printing, while similar, may result in slightly less color intensity but provides a softer hand feel and better durability, guiding decisions based on the desired texture and fabric longevity.

Rayon Printing vs Viscose Printing Infographic

materialdif.com

materialdif.com