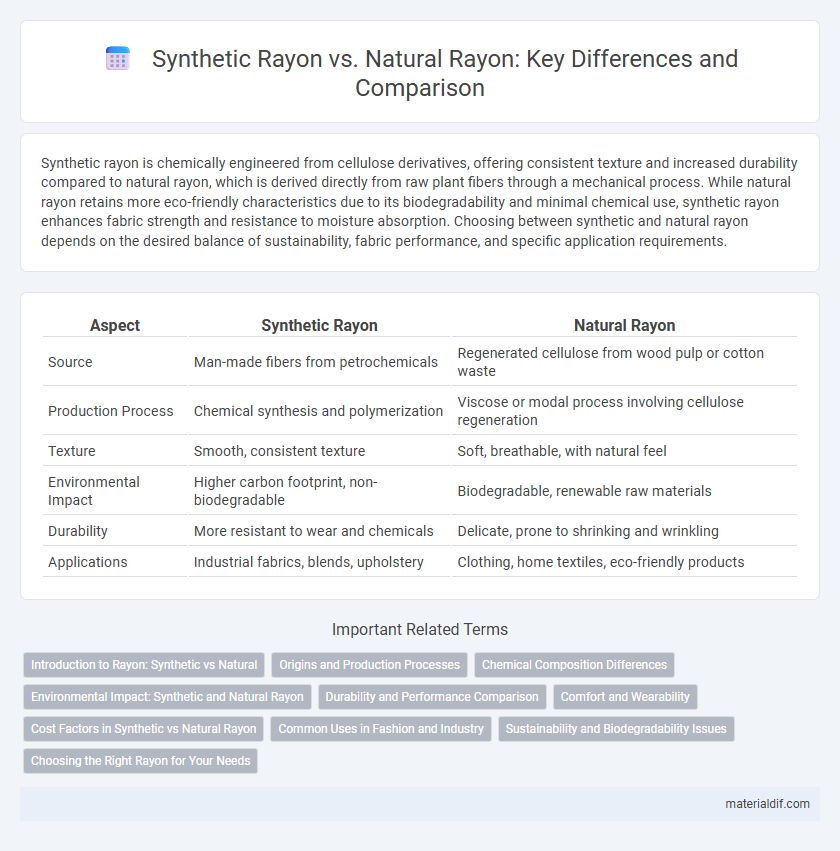

Synthetic rayon is chemically engineered from cellulose derivatives, offering consistent texture and increased durability compared to natural rayon, which is derived directly from raw plant fibers through a mechanical process. While natural rayon retains more eco-friendly characteristics due to its biodegradability and minimal chemical use, synthetic rayon enhances fabric strength and resistance to moisture absorption. Choosing between synthetic and natural rayon depends on the desired balance of sustainability, fabric performance, and specific application requirements.

Table of Comparison

| Aspect | Synthetic Rayon | Natural Rayon |

|---|---|---|

| Source | Man-made fibers from petrochemicals | Regenerated cellulose from wood pulp or cotton waste |

| Production Process | Chemical synthesis and polymerization | Viscose or modal process involving cellulose regeneration |

| Texture | Smooth, consistent texture | Soft, breathable, with natural feel |

| Environmental Impact | Higher carbon footprint, non-biodegradable | Biodegradable, renewable raw materials |

| Durability | More resistant to wear and chemicals | Delicate, prone to shrinking and wrinkling |

| Applications | Industrial fabrics, blends, upholstery | Clothing, home textiles, eco-friendly products |

Introduction to Rayon: Synthetic vs Natural

Rayon is a semi-synthetic fiber derived from natural cellulose, primarily sourced from wood pulp, making it distinct from purely synthetic fibers produced from petrochemicals. Natural rayon, often referred to as viscose, undergoes chemical processing to regenerate cellulose into fiber, offering a breathable and biodegradable alternative to fully synthetic textiles like polyester. Synthetic rayon variants, such as modal and lyocell, have enhanced durability and moisture-wicking properties due to advanced production techniques, bridging the gap between natural fiber comfort and synthetic fiber performance.

Origins and Production Processes

Synthetic rayon is derived from chemically processed cellulose fibers, primarily sourced from wood pulp combined with synthetic chemicals to enhance durability and uniformity. Natural rayon, also known as regenerated cellulose fiber, originates from natural cellulose extracted from plants like bamboo, cotton, or beech trees, undergoing fewer chemical treatments during production. The production process for synthetic rayon involves extensive chemical modifications to create fibers that mimic natural ones, whereas natural rayon production emphasizes mechanical and mild chemical processes to retain more natural fiber properties.

Chemical Composition Differences

Synthetic rayon, primarily made from chemically processed cellulose derived from wood pulp, differs from natural rayon in its extensive use of chemical solvents like carbon disulfide and sodium hydroxide during production, altering its molecular structure. Natural rayon, often referred to as viscose, retains more of the original cellulose's polymer chains with fewer chemical modifications, resulting in a fiber closer to natural cellulose in composition. These chemical differences impact properties such as tensile strength, moisture absorption, and dye affinity, distinguishing synthetic rayon as more uniform and durable compared to natural rayon's biodegradable and softer characteristics.

Environmental Impact: Synthetic and Natural Rayon

Synthetic rayon, often derived from petrochemicals, contributes significantly to environmental pollution due to its non-biodegradable nature and high energy consumption during production. Natural rayon, produced from cellulose sources like wood pulp, generally has a lower carbon footprint but can still impact forests through deforestation and chemical use in processing. Choosing sustainably sourced natural rayon with eco-friendly manufacturing processes minimizes ecological damage compared to synthetic variants.

Durability and Performance Comparison

Synthetic rayon exhibits superior durability compared to natural rayon due to its enhanced resistance to wear, moisture, and chemicals, making it ideal for high-performance applications. Natural rayon, derived from cellulose fibers, tends to absorb moisture and weaken over time, resulting in reduced tensile strength and faster degradation. Performance-wise, synthetic rayon maintains color vibrancy and structural integrity after repeated washing, while natural rayon requires more delicate care to preserve its quality.

Comfort and Wearability

Synthetic rayon offers enhanced moisture-wicking properties and greater durability, making it ideal for activewear and prolonged use. Natural rayon, derived from cellulose fibers, provides superior breathability and softness, promoting comfort in everyday wear. Both types maintain a smooth texture, but natural rayon excels in thermal regulation, ensuring better wearability in warm climates.

Cost Factors in Synthetic vs Natural Rayon

Synthetic rayon typically incurs lower production costs due to cheaper raw materials like petroleum-based chemicals and streamlined manufacturing processes. In contrast, natural rayon, derived from cellulose sources such as wood pulp, involves higher expenses related to sustainable sourcing and more complex chemical treatments. These cost differences significantly influence pricing strategies and market positioning between synthetic and natural rayon fibers.

Common Uses in Fashion and Industry

Synthetic rayon, often derived from chemically modified cellulose fibers like viscose or modal, dominates fashion for its smooth texture and ability to mimic silk, commonly used in affordable luxury dresses and linings. Natural rayon, made from untreated cellulose such as from bamboo or wood pulp, is favored in eco-conscious fashion brands for its biodegradable properties and breathability, suitable for casual wear and sustainable activewear. In industry, synthetic rayon's durability makes it ideal for upholstery, tire cords, and industrial threads, whereas natural rayon's softness is preferred for medical gauze and hygiene products.

Sustainability and Biodegradability Issues

Synthetic rayon, derived from chemically treated cellulose fibers, poses sustainability challenges due to its energy-intensive production and reliance on non-renewable resources, resulting in limited biodegradability and environmental persistence. Natural rayon, produced from sustainably sourced wood pulp with fewer chemical treatments, offers improved biodegradability and a lower carbon footprint, making it a more eco-friendly textile option. However, both types require advancements in sustainable forestry and chemical recovery processes to minimize ecological impact and enhance circularity in the textile industry.

Choosing the Right Rayon for Your Needs

Synthetic rayon, often derived from chemically treated cellulose fibers, offers enhanced durability and consistent quality, making it ideal for activewear and industrial applications. Natural rayon, produced from raw plant materials like wood pulp, provides superior breathability and softness, preferred in fashion and home textiles for comfort and eco-friendliness. Selecting the right rayon depends on balancing factors like application, desired texture, environmental impact, and performance requirements.

Synthetic Rayon vs Natural Rayon Infographic

materialdif.com

materialdif.com