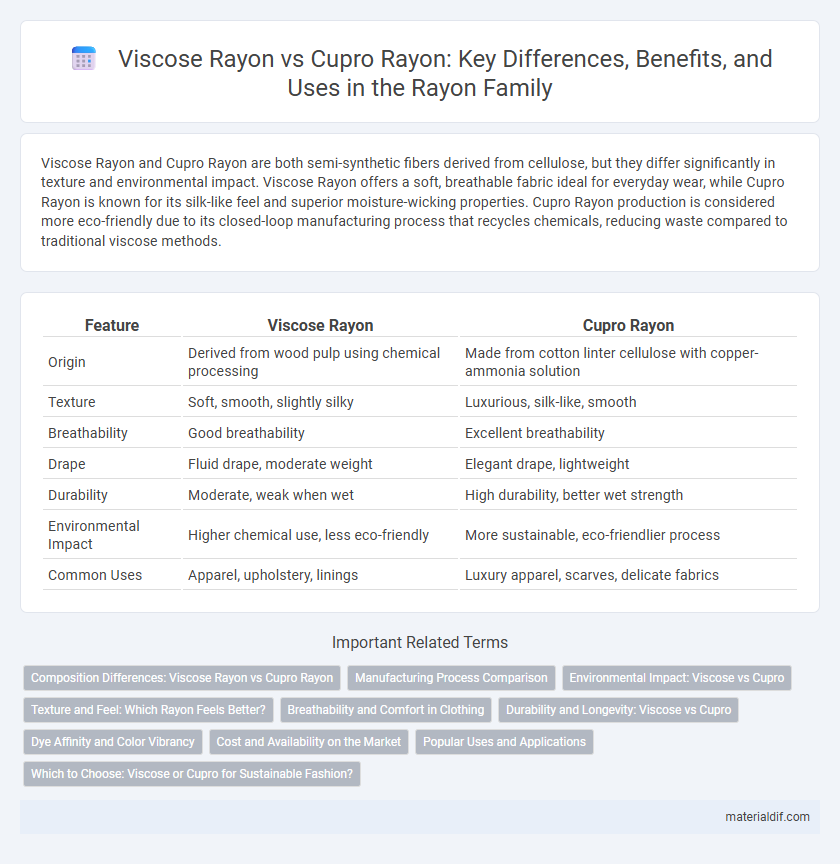

Viscose Rayon and Cupro Rayon are both semi-synthetic fibers derived from cellulose, but they differ significantly in texture and environmental impact. Viscose Rayon offers a soft, breathable fabric ideal for everyday wear, while Cupro Rayon is known for its silk-like feel and superior moisture-wicking properties. Cupro Rayon production is considered more eco-friendly due to its closed-loop manufacturing process that recycles chemicals, reducing waste compared to traditional viscose methods.

Table of Comparison

| Feature | Viscose Rayon | Cupro Rayon |

|---|---|---|

| Origin | Derived from wood pulp using chemical processing | Made from cotton linter cellulose with copper-ammonia solution |

| Texture | Soft, smooth, slightly silky | Luxurious, silk-like, smooth |

| Breathability | Good breathability | Excellent breathability |

| Drape | Fluid drape, moderate weight | Elegant drape, lightweight |

| Durability | Moderate, weak when wet | High durability, better wet strength |

| Environmental Impact | Higher chemical use, less eco-friendly | More sustainable, eco-friendlier process |

| Common Uses | Apparel, upholstery, linings | Luxury apparel, scarves, delicate fabrics |

Composition Differences: Viscose Rayon vs Cupro Rayon

Viscose rayon is primarily made from regenerated cellulose derived from wood pulp, while cupro rayon is produced using cotton linter, the fluffy fiber surrounding cotton seeds. The cellulose in viscose undergoes chemical treatment with sodium hydroxide and carbon disulfide, resulting in a semi-synthetic fabric, whereas cupro rayon involves copper ammonium solution in its regeneration process, giving it unique silk-like properties. These compositional differences influence the texture, breathability, and sustainability profiles of both fibers, making viscose versatile and cupro valued for its smooth drape and biodegradability.

Manufacturing Process Comparison

Viscose rayon is produced through the chemical treatment of cellulose with sodium hydroxide and carbon disulfide, resulting in a viscous solution that is extruded into fibers, whereas cupro rayon involves dissolving cotton linter cellulose in a copper-ammonium complex before fiber regeneration. The viscose process is more chemically intensive and environmentally taxing due to the use of carbon disulfide, while cupro rayon manufacturing employs a more sustainable solvent system with lower emissions. Both methods regenerate cellulose into semi-synthetic fibers, but cupro rayon's manufacturing offers finer fiber quality and superior moisture absorption due to its unique solvent system.

Environmental Impact: Viscose vs Cupro

Viscose rayon production involves intensive chemical processing and significant deforestation, leading to higher environmental degradation and substantial water pollution. Cupro rayon, derived from cotton linter waste, offers a more sustainable alternative with biodegradable properties and lower environmental footprint due to closed-loop chemical recovery systems. Choosing cupro rayon helps reduce resource consumption and minimizes ecological harm compared to traditional viscose rayon manufacturing.

Texture and Feel: Which Rayon Feels Better?

Viscose rayon offers a soft, smooth texture with a silky sheen, making it lightweight and breathable, ideal for comfortable everyday wear. Cupro rayon features a luxurious, silky feel with a slight stretch and a more refined, satin-like finish that drapes elegantly on the skin. While viscose rayon feels breathable and soft, cupro rayon is often preferred for its silky, smooth texture and premium hand feel.

Breathability and Comfort in Clothing

Viscose rayon offers moderate breathability and softness, making it suitable for lightweight, comfortable clothing that absorbs moisture well. Cupro rayon excels in breathability due to its fine fiber structure and smooth texture, providing superior comfort and a cool feel on the skin. Both fibers enhance fabric drape, but Cupro's natural breathability and hypoallergenic properties make it ideal for sensitive skin and warm climates.

Durability and Longevity: Viscose vs Cupro

Viscose rayon offers moderate durability with a soft texture that may weaken after repeated washing, while cupro rayon demonstrates superior longevity due to its strong fiber structure and resistance to shrinkage and pilling. Cupro maintains fabric integrity longer even under frequent use and exposure to moisture, making it a preferred choice for garments requiring extended wear. Viscose tends to degrade faster in comparison, especially when subjected to harsh laundering or abrasion.

Dye Affinity and Color Vibrancy

Viscose rayon exhibits strong dye affinity due to its hydrophilic cellulose structure, allowing vibrant and deep color absorption in fabrics. Cupro rayon, derived from regenerated cotton linter cellulose, offers exceptional color vibrancy with a smooth surface that enhances dye reflection and brightness. Both fibers achieve rich coloration, but Cupro's unique manufacturing process results in glossier and more luminous hues compared to the softer, matte finish of viscose rayon.

Cost and Availability on the Market

Viscose rayon is widely available and cost-effective due to its mass production from wood pulp, making it a popular choice in the textile industry. Cupro rayon, derived from cotton linter, tends to be more expensive because of its complex manufacturing process and limited supply. Market availability of viscose rayon is significantly higher, while cupro rayon occupies a niche segment favored for premium fabrics.

Popular Uses and Applications

Viscose rayon is widely used in apparel such as dresses, linings, and blouses due to its silky texture and breathability. Cupro rayon, derived from cotton linter, is popular in luxury fashion and high-end linings because of its smooth feel and excellent drape. Both fibers serve key roles in textile manufacturing, with viscose favored for everyday wear and cupro for premium garments.

Which to Choose: Viscose or Cupro for Sustainable Fashion?

Viscose rayon, derived from wood pulp and commonly used in fast fashion, offers breathability and affordability but often involves chemical-intensive processes that impact sustainability. Cupro rayon, made from regenerated cellulose fibers of cotton linter, provides a smoother texture, biodegradability, and a lower environmental footprint due to its closed-loop production method. For sustainable fashion, Cupro's eco-friendly manufacturing and superior quality make it a preferred choice over conventional viscose rayon.

Viscose Rayon vs Cupro Rayon Infographic

materialdif.com

materialdif.com