Eco Rayon is produced using environmentally friendly methods that minimize chemical usage and reduce water consumption compared to conventional rayon. This sustainable process lowers the ecological footprint by utilizing renewable raw materials and adopting closed-loop systems for solvent recovery. As a result, Eco Rayon offers a greener alternative while maintaining the soft texture and breathability associated with traditional rayon fabrics.

Table of Comparison

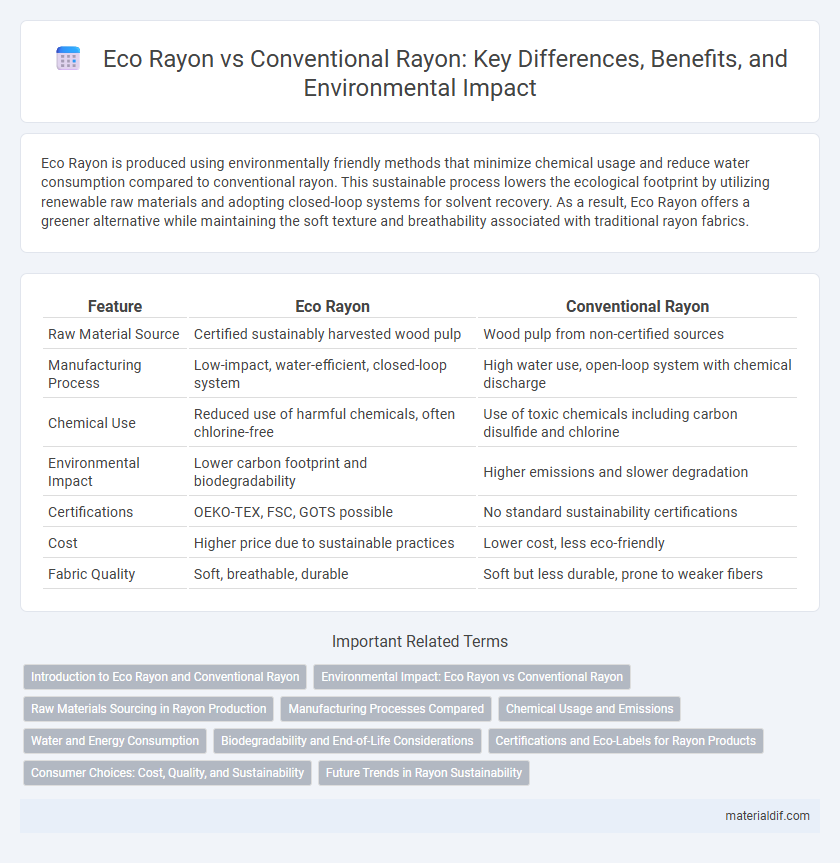

| Feature | Eco Rayon | Conventional Rayon |

|---|---|---|

| Raw Material Source | Certified sustainably harvested wood pulp | Wood pulp from non-certified sources |

| Manufacturing Process | Low-impact, water-efficient, closed-loop system | High water use, open-loop system with chemical discharge |

| Chemical Use | Reduced use of harmful chemicals, often chlorine-free | Use of toxic chemicals including carbon disulfide and chlorine |

| Environmental Impact | Lower carbon footprint and biodegradability | Higher emissions and slower degradation |

| Certifications | OEKO-TEX, FSC, GOTS possible | No standard sustainability certifications |

| Cost | Higher price due to sustainable practices | Lower cost, less eco-friendly |

| Fabric Quality | Soft, breathable, durable | Soft but less durable, prone to weaker fibers |

Introduction to Eco Rayon and Conventional Rayon

Eco Rayon is a sustainable alternative to conventional rayon, produced using environmentally friendly processes that reduce chemical use and water consumption. Conventional rayon, also known as viscose, involves intensive chemical treatment of wood pulp, often causing environmental pollution and resource depletion. The shift towards Eco Rayon reflects increasing consumer demand for eco-conscious textiles with lower ecological impact.

Environmental Impact: Eco Rayon vs Conventional Rayon

Eco Rayon significantly reduces environmental impact compared to conventional rayon by utilizing closed-loop production processes that recycle chemicals and minimize water pollution. Conventional rayon manufacturing often involves toxic solvents like carbon disulfide, resulting in high emissions and deforestation due to intensive wood pulp sourcing. Choosing eco-friendly rayon supports sustainable forestry and lowers greenhouse gas emissions, promoting a healthier ecosystem and reducing industrial waste.

Raw Materials Sourcing in Rayon Production

Eco Rayon differentiates itself from conventional rayon through sustainable raw material sourcing, primarily using wood pulp from certified responsibly managed forests such as FSC or PEFC. Conventional rayon typically relies on pulp sourced from non-certified forests, contributing to deforestation and loss of biodiversity. The use of renewable and traceable raw materials in Eco Rayon reduces environmental impact and supports ethical forestry practices.

Manufacturing Processes Compared

Eco Rayon is produced using closed-loop manufacturing processes that recycle chemicals and minimize water and energy consumption, significantly reducing environmental impact. Conventional Rayon typically uses open-loop processes with toxic chemicals like carbon disulfide, resulting in higher emissions and waste generation. The sustainable approach in Eco Rayon manufacturing enhances resource efficiency and reduces pollution compared to traditional methods.

Chemical Usage and Emissions

Eco rayon significantly reduces chemical usage by employing closed-loop processes that recycle solvents like carbon disulfide, minimizing environmental pollution. Conventional rayon involves extensive use of toxic chemicals such as carbon disulfide and sulfuric acid, leading to higher emissions and greater ecological harm. The improved chemical management in eco rayon production results in lower greenhouse gas emissions and reduced contamination of air and water resources.

Water and Energy Consumption

Eco Rayon production significantly reduces water consumption by using closed-loop processes that recycle water, contrasting with conventional Rayon manufacturing which consumes large quantities of fresh water. Energy usage in Eco Rayon is optimized through sustainable practices and renewable energy sources, whereas conventional Rayon relies heavily on energy-intensive chemical treatments and fossil fuels. These efficiencies in Eco Rayon contribute to a lower environmental footprint and support sustainable textile production.

Biodegradability and End-of-Life Considerations

Eco rayon demonstrates superior biodegradability compared to conventional rayon due to its production from sustainably sourced raw materials and reduced chemical treatments. The end-of-life impact of eco rayon is significantly lower, as it decomposes more efficiently in natural environments, minimizing landfill accumulation and environmental pollution. Conventional rayon often involves harsher chemicals and less sustainable practices, resulting in slower degradation and more ecological burden during disposal.

Certifications and Eco-Labels for Rayon Products

Eco Rayon products often carry certifications such as OEKO-TEX Standard 100, GOTS (Global Organic Textile Standard), and FSC (Forest Stewardship Council), ensuring sustainable sourcing and low environmental impact. Conventional Rayon typically lacks these eco-labels, reflecting less stringent controls on chemical usage and deforestation practices. Certifications play a crucial role in verifying the eco-friendliness of rayon by promoting responsible forestry and non-toxic production processes.

Consumer Choices: Cost, Quality, and Sustainability

Eco rayon offers consumers a sustainable alternative to conventional rayon by utilizing environmentally friendly processes that reduce toxic chemical use and water consumption. While conventional rayon tends to be more affordable, eco rayon often justifies a higher price through improved quality and reduced environmental impact, appealing to environmentally conscious buyers. Consumer choices increasingly favor eco rayon for its balance of durability, softness, and contribution to sustainable fashion practices.

Future Trends in Rayon Sustainability

Eco rayon production employs closed-loop processes that significantly reduce chemical waste and water consumption compared to conventional rayon, addressing critical environmental concerns. Innovations in bio-based solvents and regenerative agriculture for cellulose sourcing are driving the future of sustainable rayon, enhancing biodegradability and carbon footprint reduction. Industry investments in transparent supply chains and recyclable fabric technologies signal a shift towards circular economy models for rayon materials.

Eco Rayon vs Conventional Rayon Infographic

materialdif.com

materialdif.com